Method for removing bitter taste in oat bran dairy product

A technology of oat bran and oat bran powder, applied in dairy products, milk substitutes, applications, etc., can solve problems such as rough taste of oat bran, no high calorie of oatmeal, and no treatment method, so as to improve nutritional value , Improve product quality and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

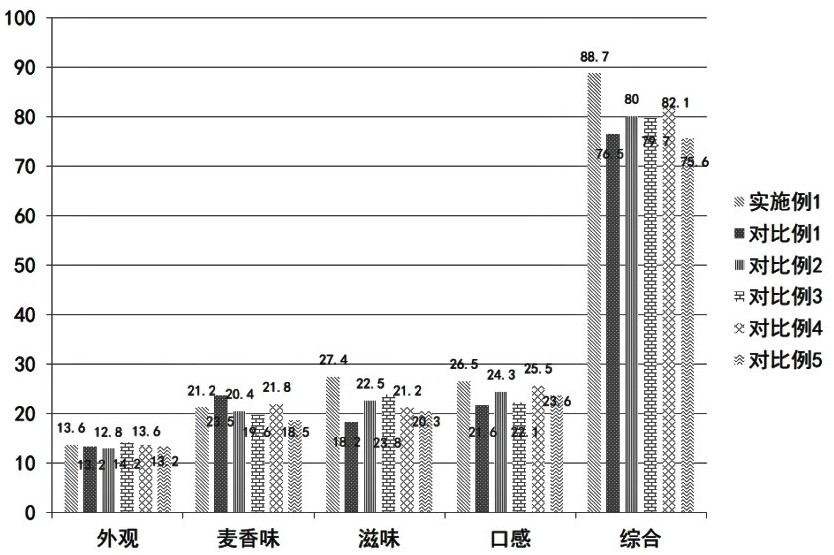

Examples

Embodiment 1

[0038] A way to remove bitterness from oat bran dairy products:

[0039] (1) Raw material acceptance: select 80 mesh oat bran powder;

[0040] (2) Baking: Pour the oat bran powder into the baking tray, spread it evenly, with a thickness of 1.5cm, put it in the oven to bake, the baking temperature is 150°C, and the baking time is 10 minutes;

[0041] (3) Wet beating: Put the baked oat bran powder into the wall breaking machine, add water 5 times the weight of the oat bran powder, stir evenly, turn on the beating, until the slurry is in a uniform state without obvious particles That’s it, get the oat bran slurry, pour it out for later use;

[0042] (4) Enzymolysis:

[0043] ①The first step of enzymatic hydrolysis: Weigh 800 parts of oat bran slurry into a container, weigh 0.7 parts of α-amylase (ALT), dilute and mix α-amylase (ALT) with warm water 10 times its weight, Add the fermented oat bran slurry and mix well, put it in an incubator to start enzymolysis, the temperature ...

Embodiment 2

[0052] A way to remove bitterness from oat bran dairy products:

[0053] (1) Raw material acceptance: select 80 mesh oat bran powder;

[0054] (2) Baking: Pour the oat bran powder into the baking tray, spread it evenly, with a thickness of 1cm, put it in the oven to bake, the baking temperature is 155°C, and the baking time is 9 minutes;

[0055] (3) Wet beating: Put the baked oat bran powder into the wall breaking machine, add water 5 times the weight of the oat bran powder, stir evenly, turn on the beating, until the slurry is in a uniform state without obvious particles That’s it, get the oat bran slurry, pour it out for later use;

[0056] (4) Enzymolysis:

[0057] ①The first step of enzymatic hydrolysis: Weigh 800 parts of oat bran slurry into a container, weigh 0.8 parts of α-amylase (ALT), dilute and mix α-amylase (ALT) with warm water 10 times its weight, Add the fermented oat bran slurry and mix well, put it in an incubator to start enzymolysis, the temperature is ...

Embodiment 3

[0066] A way to remove bitterness from oat bran dairy products:

[0067] (1) Raw material acceptance: select 80 mesh oat bran powder;

[0068] (2) Baking: Pour the oat bran powder into the baking tray, spread it evenly, with a thickness of 1.5cm, put it in the oven to bake, the baking temperature is 160°C, and the baking time is 8 minutes;

[0069] (3) Wet beating: Put the baked oat bran powder into the wall breaking machine, add water 6 times the weight of the oat bran powder, stir evenly, turn on the beating, until the slurry state is uniform without obvious particles That’s it, get the oat bran slurry, pour it out for later use;

[0070] (4) Enzymolysis:

[0071] ①The first step of enzymatic hydrolysis: Weigh 600 parts of oat bran slurry into a container, weigh 0.8 parts of α-amylase (ALT), dilute and mix α-amylase (ALT) with warm water 10 times its weight, Add the fermented oat bran slurry and mix well, place it in an incubator to start enzymolysis, the temperature is 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com