Glass edge detection method and system based on machine vision

A technology of glass edge and machine vision, applied in instruments, image data processing, computing, etc., can solve the problems of high missed detection rate, high labor cost, low accuracy of manual inspection, etc., achieve controllable size and specification, reduce labor cost, The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of the present application.

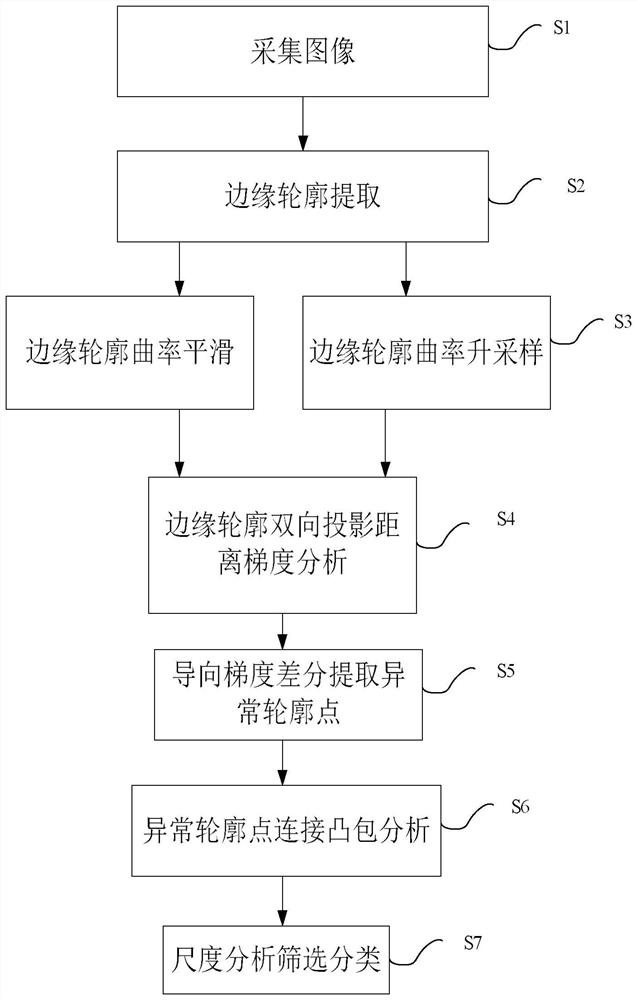

[0047] see figure 1 , in one embodiment, the method for glass edge defect detection based on machine vision of the present invention comprises the following steps:

[0048] S1: Use a line-scan camera to scan and image the edge of the glass in the measurement area to obtain an image of the edge of the glass.

[0049] S2: Using the gradient analysis method to analyze the glass edge image, and extract the glass edge profile.

[0050] The extraction of edge contours is divided into four parts:

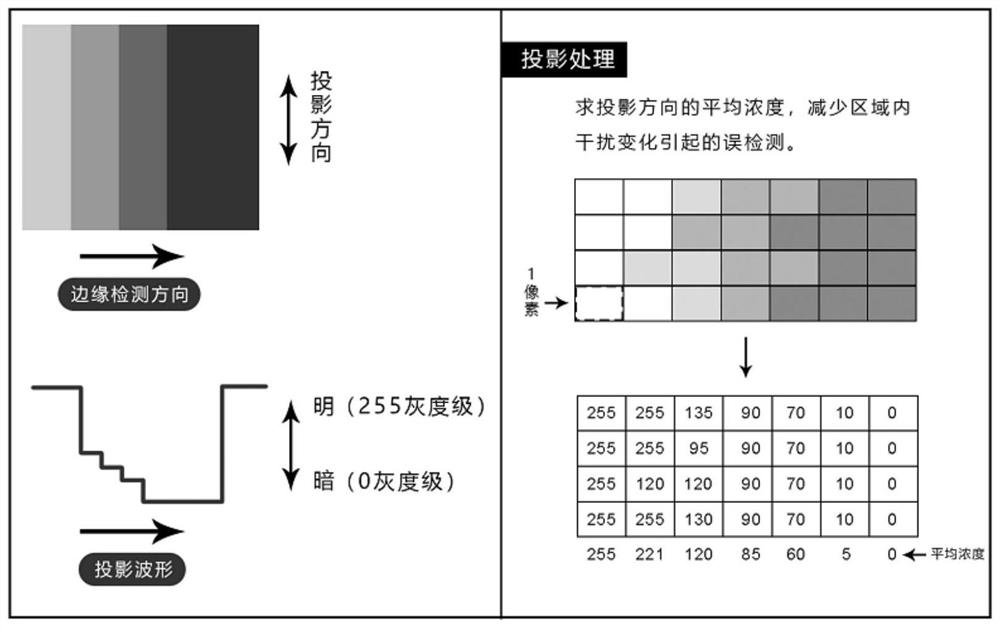

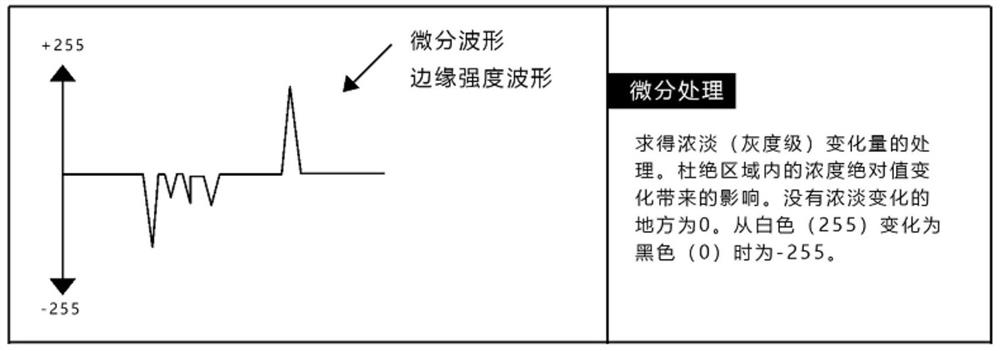

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com