Concrete support servo system and construction monitoring and control method thereof

A technology of servo system and control method, which is applied in excavation, measuring devices, infrastructure engineering, etc., can solve the problems that the safety of the foundation pit cannot be better guaranteed, the supporting axial force cannot be adjusted actively, and the time is uncontrollable, etc., to achieve Ensure the safety of foundation pit construction, reduce the laying of cables, and ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

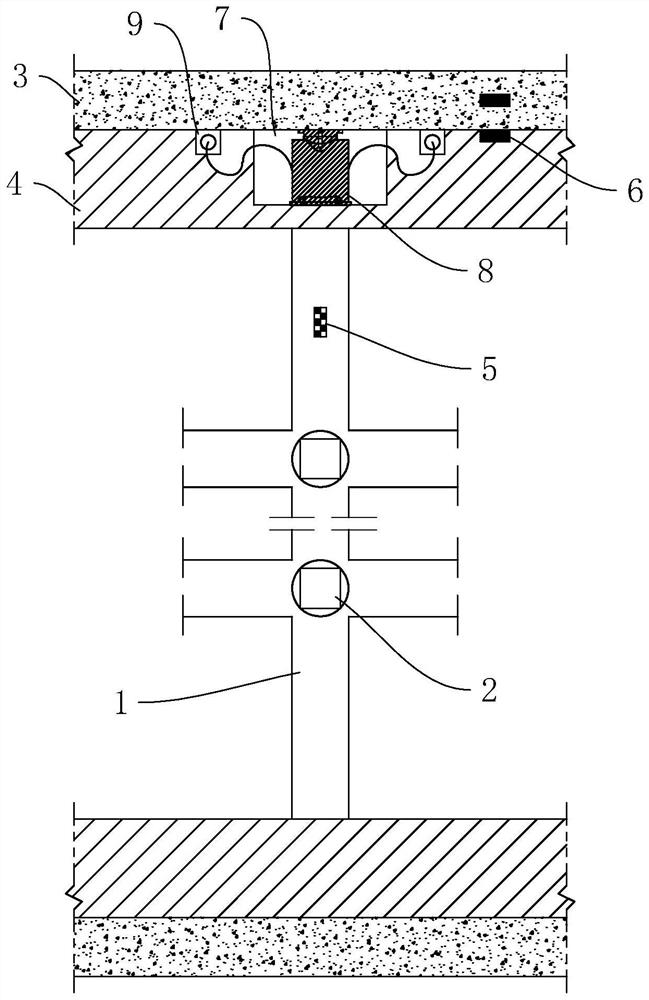

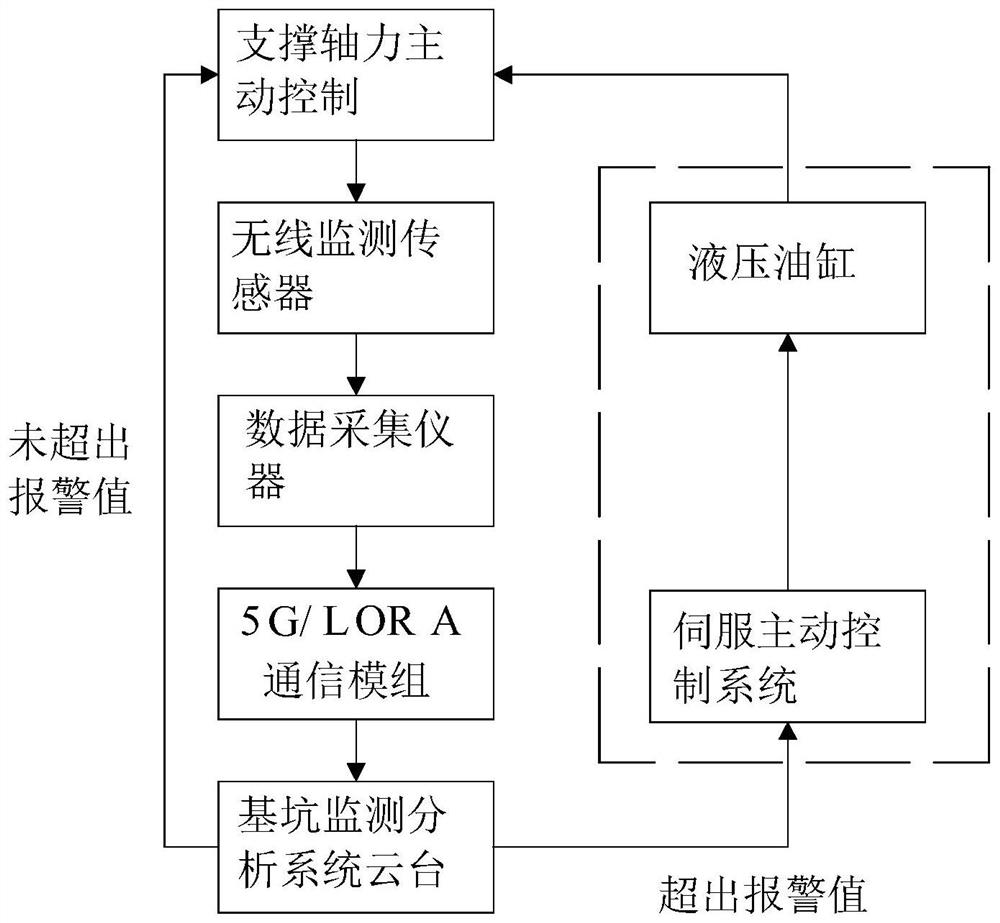

[0045] The following conjunction with the accompanying Figure 1-4 The present application as described in further detail.

[0046] A support for a concrete embodiment of the servo system disclosed herein.

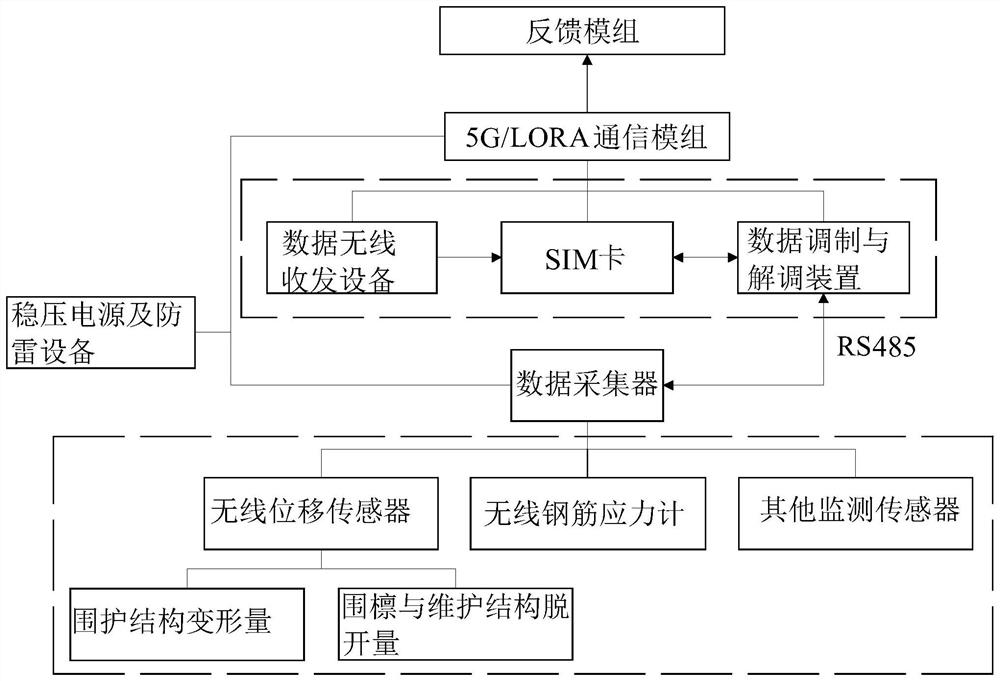

[0047] Refer figure 1 and figure 2 A concrete support of the servo system, and a data structure including dispatched feedback system.

[0048] Refer figure 1 and figure 2 The data feedback system includes a data collector, the data collector is a wireless steel stress meter 5 and a wireless displacement sensor 6, which is mainly used to collect monitoring data in the foundation pit;

[0049] Refer figure 1 and figure 2 , Communication module, communication module is 5G / LORA module, communication module includes SIM card, data transmission and receiving equipment, and data modulation and demodulation devices, data modulation and demodulation devices pass the monitoring of data acquisition instruments through the RS485 protocol The data is processed, realizing the conversion of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com