Device for expanding compaction contact surface of road roller

A road roller and contact surface technology, which is applied in the field of roadbed filling construction, can solve the problems of fragility, weak cohesion, environmental problems, etc., and achieve the effect of expanding the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

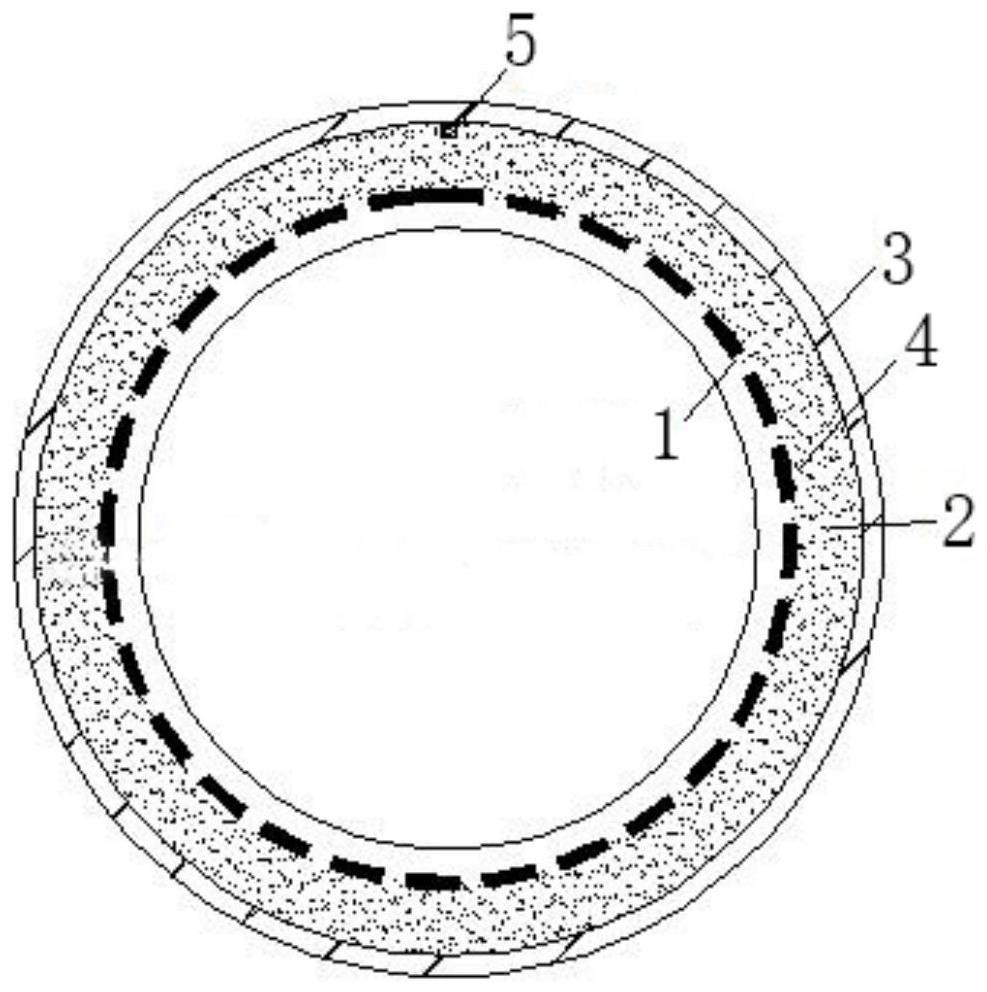

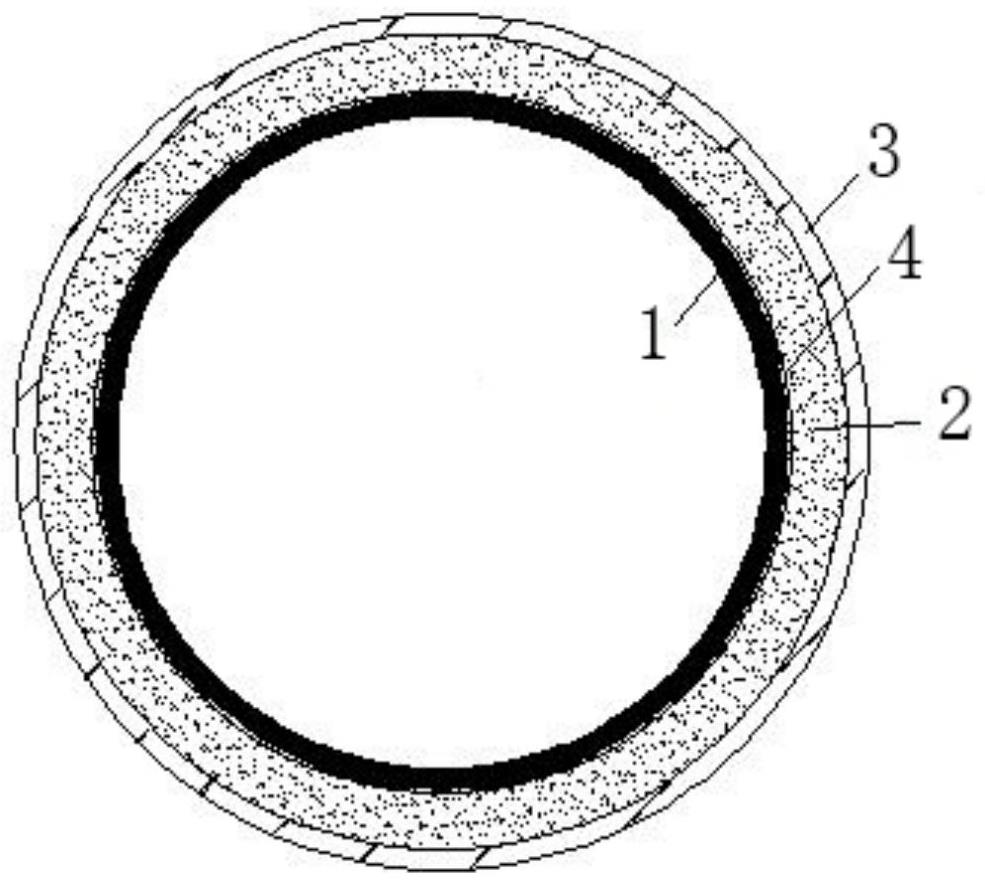

[0015] Such as figure 1 and 2 The shown device for enlarging the compaction contact surface of the road roller includes a sealing bag and a rubber pad layer nested sequentially from the inside to the outside; the sealing bag also includes a sealing layer that closely fits the outer peripheral surface of the vibrating wheel of the road roller and Zircon sand filled in the capsule; specifically, the thickness of the sealing layer is 0.5cm; the total thickness of the sealed capsule and the zircon sand cushion after filling is 6cm; the rubber cushion is made of wear-resistant rubber with a thickness of 1.5cm .

[0016] When fully weathered red sandstone or silty sand is used as subgrade filler, in order to avoid poor cohesion and uniform particle size that cannot be effectively compacted, it is necessary to provide certain lateral constraints ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com