Coke quenching control method and device for coke cooling table, terminal and coke quenching system

A control method and coke quenching technology, which is applied in the field of coke quenching system, can solve problems such as burn-through, belt burnout, and production impact, and achieve the effect of improving efficiency and avoiding missed judgments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

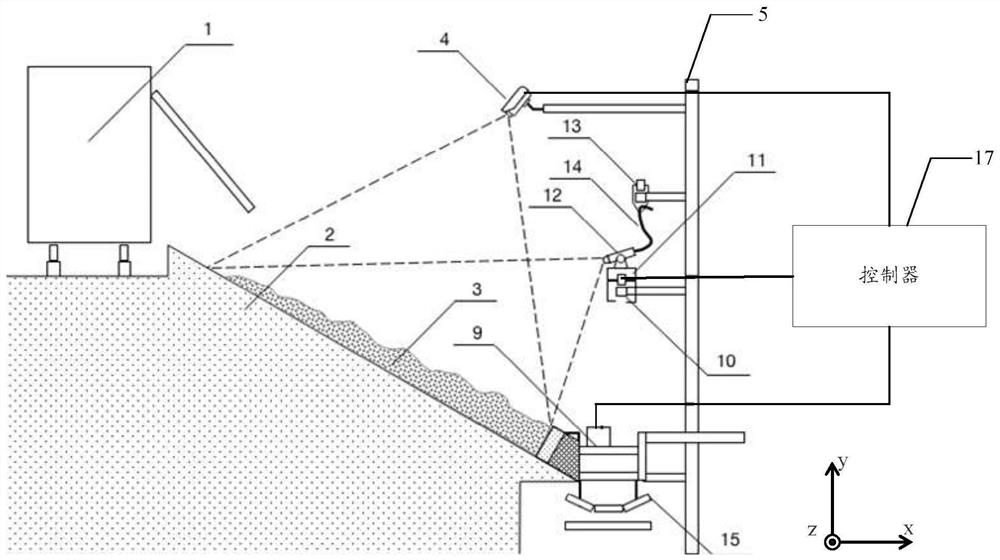

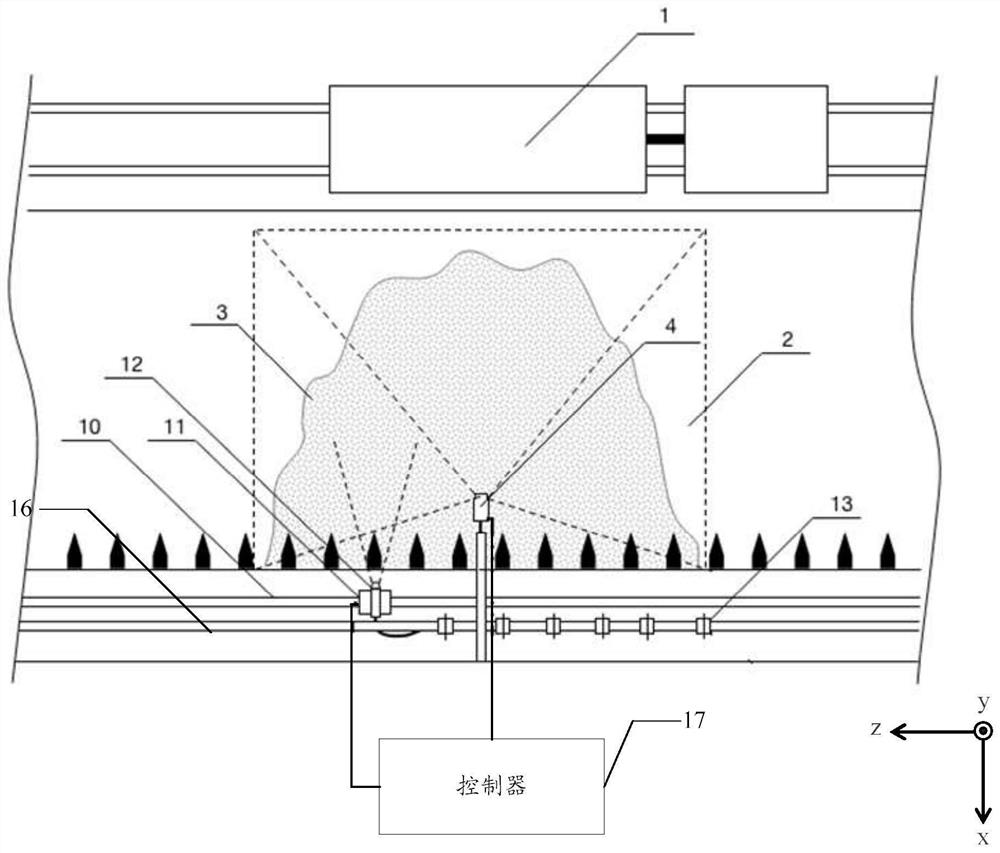

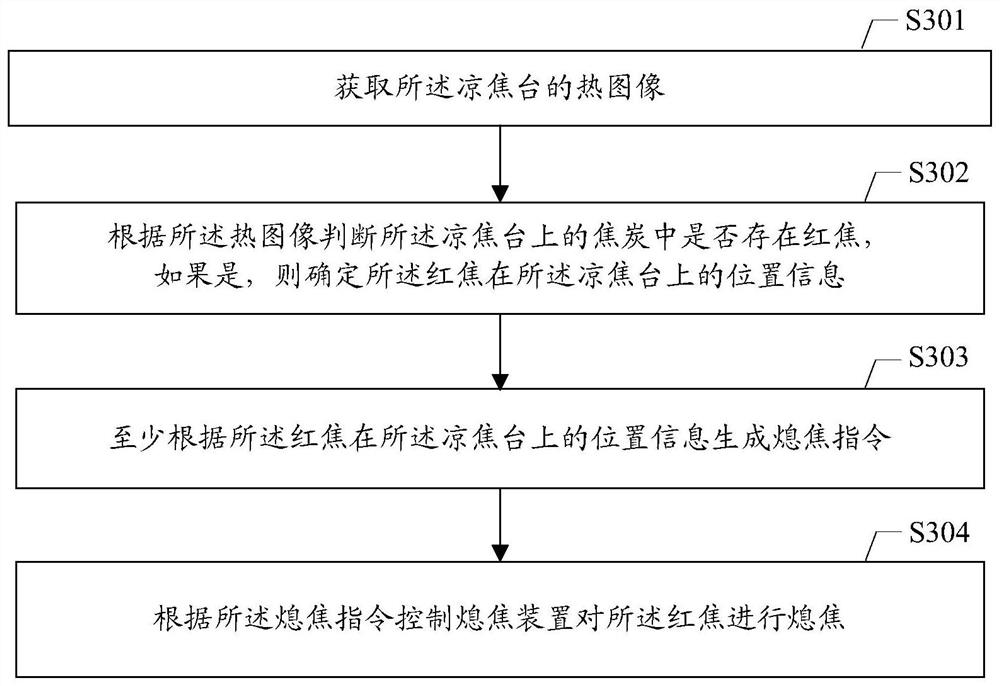

[0031] As mentioned in the background technology, there is an urgent need for a coke quenching method that can fully identify the red coke in the coke on the coke cooling platform, and perform secondary quenching to avoid safety accidents caused by red coke.

[0032]The inventors of the present invention have found through research that in the prior art, the coke on the coke cooling platform is usually observed manually and the coke is quenched twice. Specifically, water pipes are laid on the coke cooling platform, a water supply point is set at a certain distance, and a nozzle and a rubber hose are installed at each water supply point. After each unloading of coke, the on-site personnel will monitor whether there is red coke on the coke cooling platform. When red coke is found, open the nearest water supply valve, drag the nozzle to the red coke and aim at the spray water until no red coke is observed. After the coking phenomenon, close the valve and continue to patrol. Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com