Method for degrading azo dye through photo-enzyme catalysis

A photo-enzyme catalyzed azo and azo technology, applied in chemical instruments and methods, water pollutants, water treatment of special compounds, etc. The effect of high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Photocatalyst Au-TiO 2 preparation of

[0029] The AuCl used in this example 3 and TiO 2 (Anatase or rutile, 10-25nm) were purchased from Anaiji Chemical. Photocatalyst Au-TiO 2 The preparation method is as follows: 5mM AuCl 3 The solution (77.5mg 98% gold chloride dissolved in 50mL deionized water) was heated to 70°C, and the pH was adjusted to 7.2 with 0.1M NaOH solution; 97mL deionized water was taken and heated to 70°C, and 11mL of the above-mentioned AuCl was added 3 solution, stirred for 10 minutes, added 1g TiO 2 Granulate and stir at 70°C for 1 hour. Cool to room temperature, centrifuge at a rate of 6000rpm for 15 minutes, wash three times with deionized water and centrifuge to remove the supernatant, dry overnight at 70°C (about 1.1% Au), photocatalyst Au-TiO 2 (According to the different raw materials, it is divided into anatase Au-TiO 2 or rutile Au-TiO 2 ).

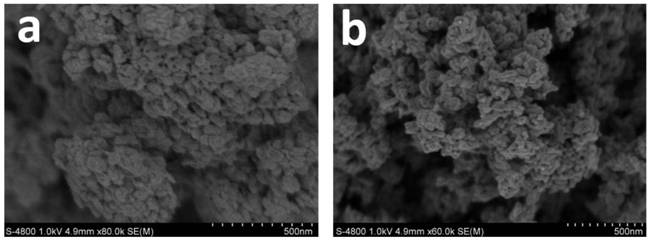

[0030] Under the scanning electron microscope, we found that the anatase and rut...

Embodiment 2

[0031] Embodiment 2 light-enzyme catalyzes the degradation of acid red 1

[0032] The reaction conditions were: Acid Red 1 dye concentration of 0.05 mml / L, disodium phosphate-citrate buffer at pH=4, 0.2 mg / mL HRP and 0.5 mg / mL Au-TiO 2 As a catalyst, react at 25°C to investigate the catalytic effect of two different crystal photocatalysts, the results are shown in Table 1. We found that under the same conditions, the anatase Au-TiO 2 With high catalytic activity, 80% of acid red dye can be degraded in 5 minutes when combined with HRP, and the degradation rate can be increased to 85% if the time is extended to 15 minutes; while rutile Au-TiO 2 It can also cooperate with enzymes to catalyze the degradation of dyes, with degradation rates of 62% and 81% in 5 minutes and 15 minutes, respectively. combine Figure 4 The scanning electron microscope image, we speculate that it may be anatase Au-TiO 2 Has a regular surface structure, large specific surface area, high catalytic eff...

Embodiment 3

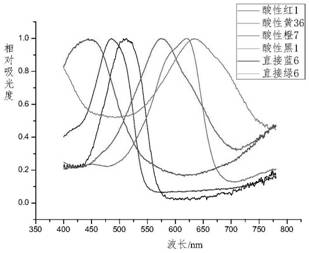

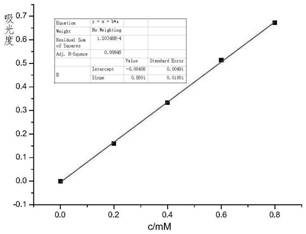

[0037] Embodiment 3 photo-enzyme catalytic system is to the degradation effect of various dyes

[0038] Under this catalytic system, we selected 5 kinds of dyes for degradation test, the results are as follows: Image 6 shown. Regardless of the dyes with monoazo, disazo or trisazo structures, no matter what color system the dyes are, the photo-enzyme catalytic system established in this study has a good catalytic degradation effect. Among them, Direct Green 6, which has the most complex structure and the largest molecular weight, has the highest degradation rate of 86%, while Acid Orange 7, which has the smallest molecular mass and the simplest structure, has the lowest degradation rate of only 49%. In the system, the influence of the type of dye on the catalytic efficiency is actually multifaceted. On the one hand, the color of the dye will affect the wavelength and energy of light absorbed by the photocatalyst. On the other hand, the dye is catalyzed and degraded in the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com