Clamping tool for track link section finish machining

A technology for clamping tooling and chain rail links, which is applied to metal processing equipment, metal processing machine parts, clamping, etc., and can solve problems affecting the processing accuracy of chain rail links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

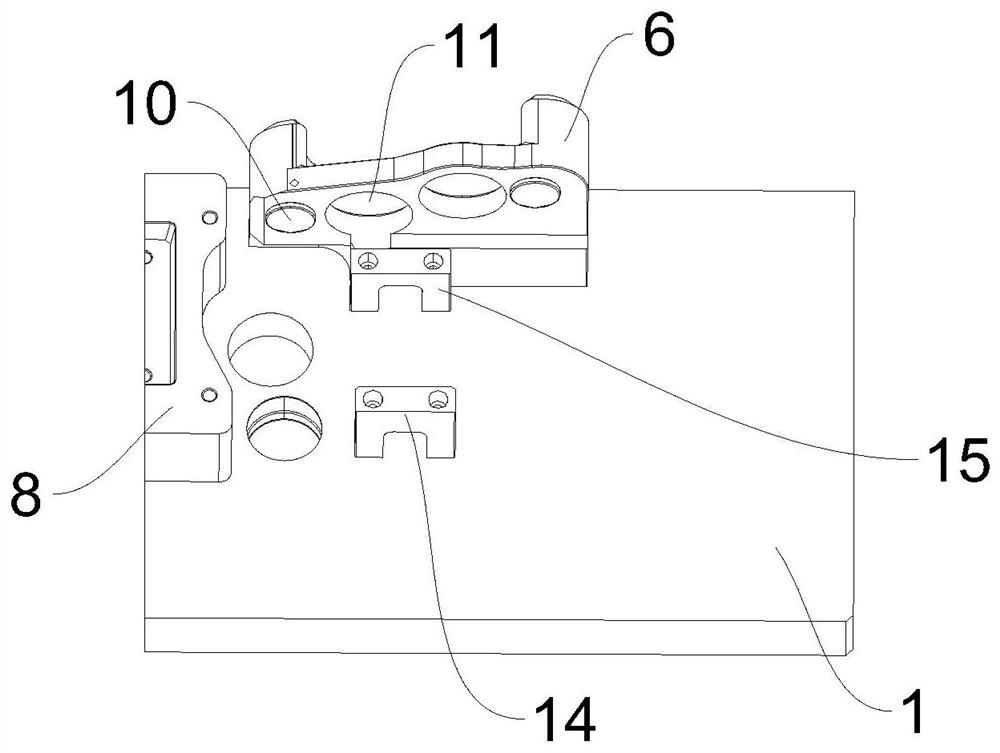

[0032] Please refer to Figure 1-Figure 3 shown. This embodiment provides a clamping tool for the finishing of chain rail links, including a mounting base 1, a first hydraulic cylinder 13 disposed on one side of the mounting base 1, and a second hydraulic cylinder 12 disposed on the other side of the mounting base 1, One side of the installation base plate 1 is provided with a rotary cylinder 3 that cooperates with the first hydraulic cylinder 13, and the output end of the rotary cylinder 3 is connected with a rotary platen 4, and the other side of the installation base plate 1 is provided with a limiter that cooperates with the second hydraulic cylinder 12. bit piece 8.

[0033]In the above-mentioned embodiment, the clamping tool for the finishing of the chain rail link 2 is composed of the installation base plate 1, the first hydraulic cylinder 13 and the second hydraulic cylinder 12, wherein the first hydraulic cylinder 13 is located on one side of the installation base pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com