Method for improving yield of iron casting product inoculation nodulizer

A nodulizer and iron casting technology, which is applied in the field of improving the yield of inoculant nodulizers for iron castings, can solve problems such as slag inclusion in castings, affecting the quality of castings, and improper handling of slag removal, so as to slow down the melting speed and reduce Quality risk, effect of increasing float time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

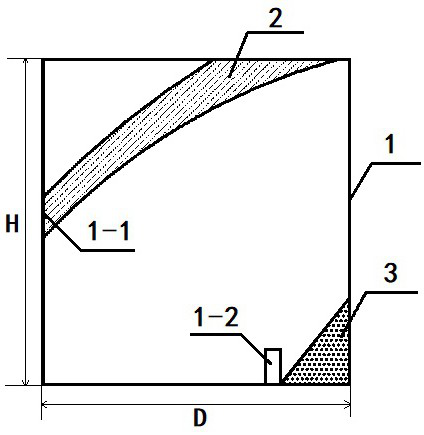

[0026] Such as figure 1 As shown, a method for improving the yield of inoculant nodularizing agent for cast iron products comprises the following steps:

[0027] Step 1, optimize the structure of the ladle 1; the optimization of the structure of the ladle 1 specifically means that the position of the molten iron 2 of the ladle 1 corresponds to the middle part of the ladle 1-1; the height-diameter ratio H:D of the ladle 1 is reduced; the bottom of the ladle dam 1 -2 is set on the backwater side of the ladle bottom (the side where the covering chips, inoculants and nodulizers are placed), and adjust the height of the dam 1-2 at the bottom of the ladle; the height-to-diameter ratio H:D of ladle 1 is 0.9 to 1.0 ; The height of the bottom retaining dam 1-2 is set to 200mm.

[0028] Step 2, put the covering chips, inoculants, and nodulizers on the side of the ladle bottom dam 1-2 at position 3 where the covering chips, inoculants, and nodulizers are placed; The overall height is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com