Preparation method of perovskite precursor solution and perovskite thin film

A perovskite precursor and perovskite technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as complex methods, achieve simple process costs, avoid uneven nucleation, prolong Effect of wet film post-processing time window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of perovskite film of the present invention comprises the following steps:

[0036] a, providing the above-mentioned perovskite precursor solution;

[0037] b. Film production: apply the perovskite precursor solution on the substrate to obtain a wet film, then process the wet film to obtain a perovskite dry film, and finally perform annealing to obtain a perovskite film.

[0038] Commonly used methods of applying solutions to substrates can be used in the present invention. In some embodiments of the present invention, the perovskite precursor solution is coated on the substrate by coating, blade coating or spin coating.

[0039] The substrate material is a conventional material in the art, including but not limited to rigid substrates such as glass substrates and flexible plastic substrates, such as polyimide (PI), polyamide (PA), polyethylene terephthalate (PET), Polytetrafluoroethylene (PTFE), polypropylene (PP), various modified polystyrene ...

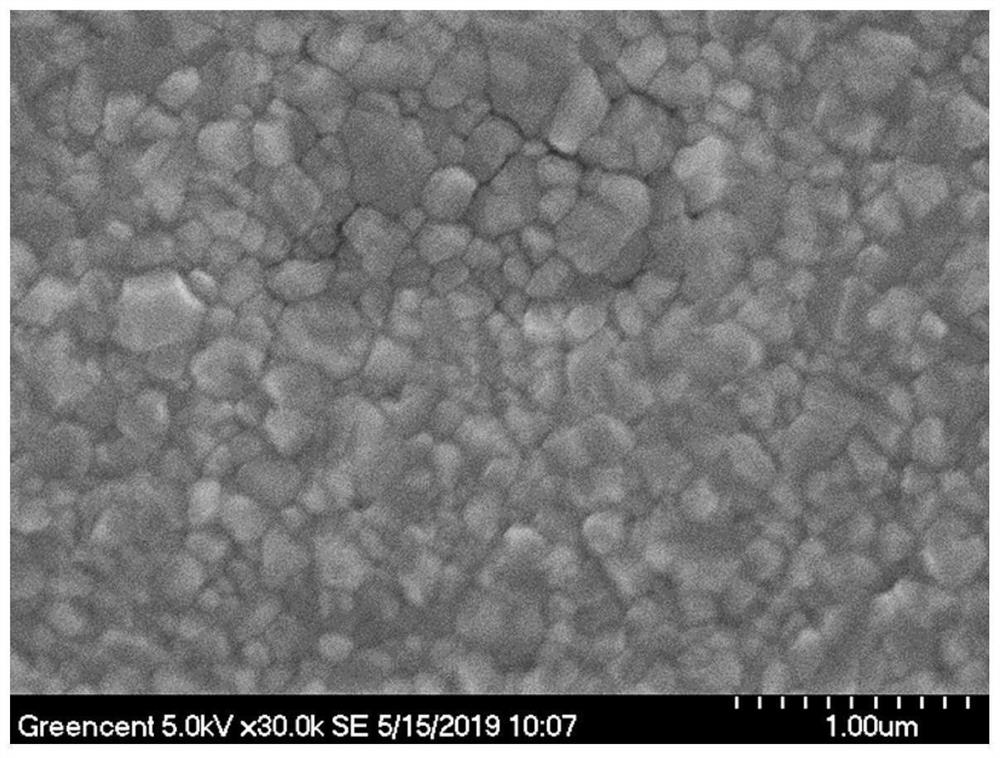

Embodiment 1

[0043] A mixed solvent with a component of DMF:NMP=1:0.05 is used, and the solute component is Cs 0.2 FA 0.8 Pb(I 0.95 Br 0.05 ) 3 perovskite precursor solution, the concentration of the solution is 0.5mol / L, and the perovskite film is prepared by using the method of scrape coating and gas blowing. The surface SEM image of the obtained film is shown in figure 1 , it can be seen that there is no hole on the surface of the film and the coverage is comprehensive.

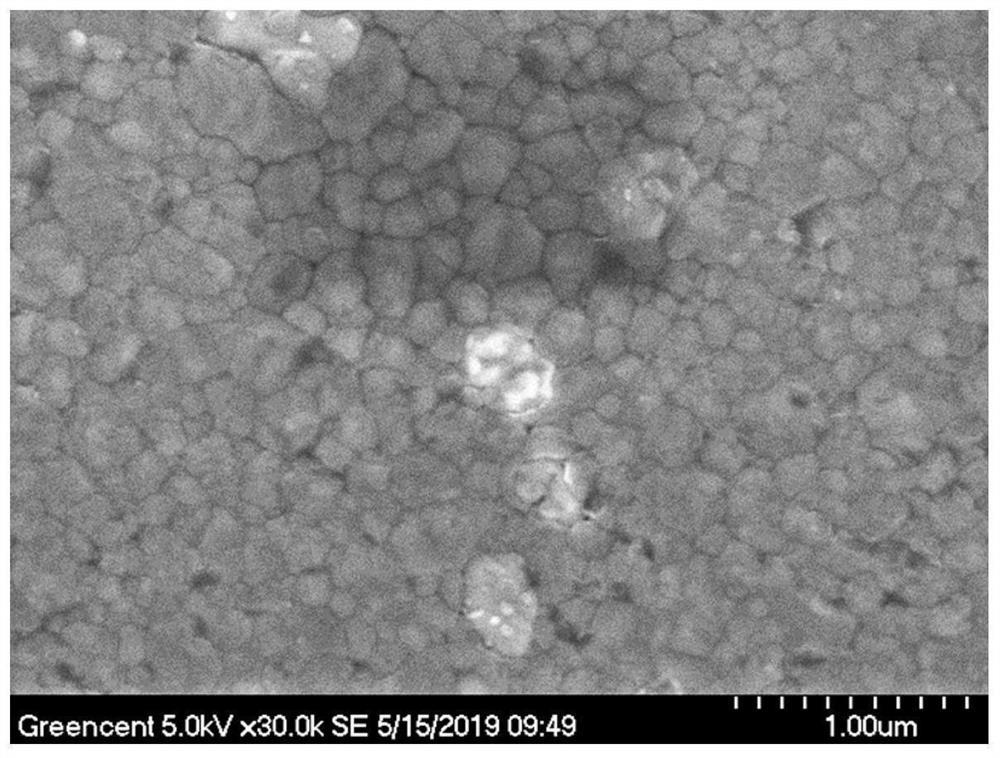

Embodiment 2

[0045] Adopt the mixed solvent that the component is DMF:NMP=1:0.10, equip the solute component as Cs 0.2 FA 0.8 Pb(I0.95 Br 0.05 ) 3 perovskite precursor solution, and the perovskite film was prepared by using the scrape coating process and blowing assistance method, the surface SEM image of the obtained film is shown in figure 2 , it can be seen that there is no hole on the surface of the film, and the coverage is comprehensive, but there are a few impurity grains on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com