Thin film form control device based on visual camera shooting detection technology

A detection technology and control device technology, which is applied in the field of thin film shape control devices, can solve problems such as low rigidity and lack of mechanical analysis of film bending strength, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

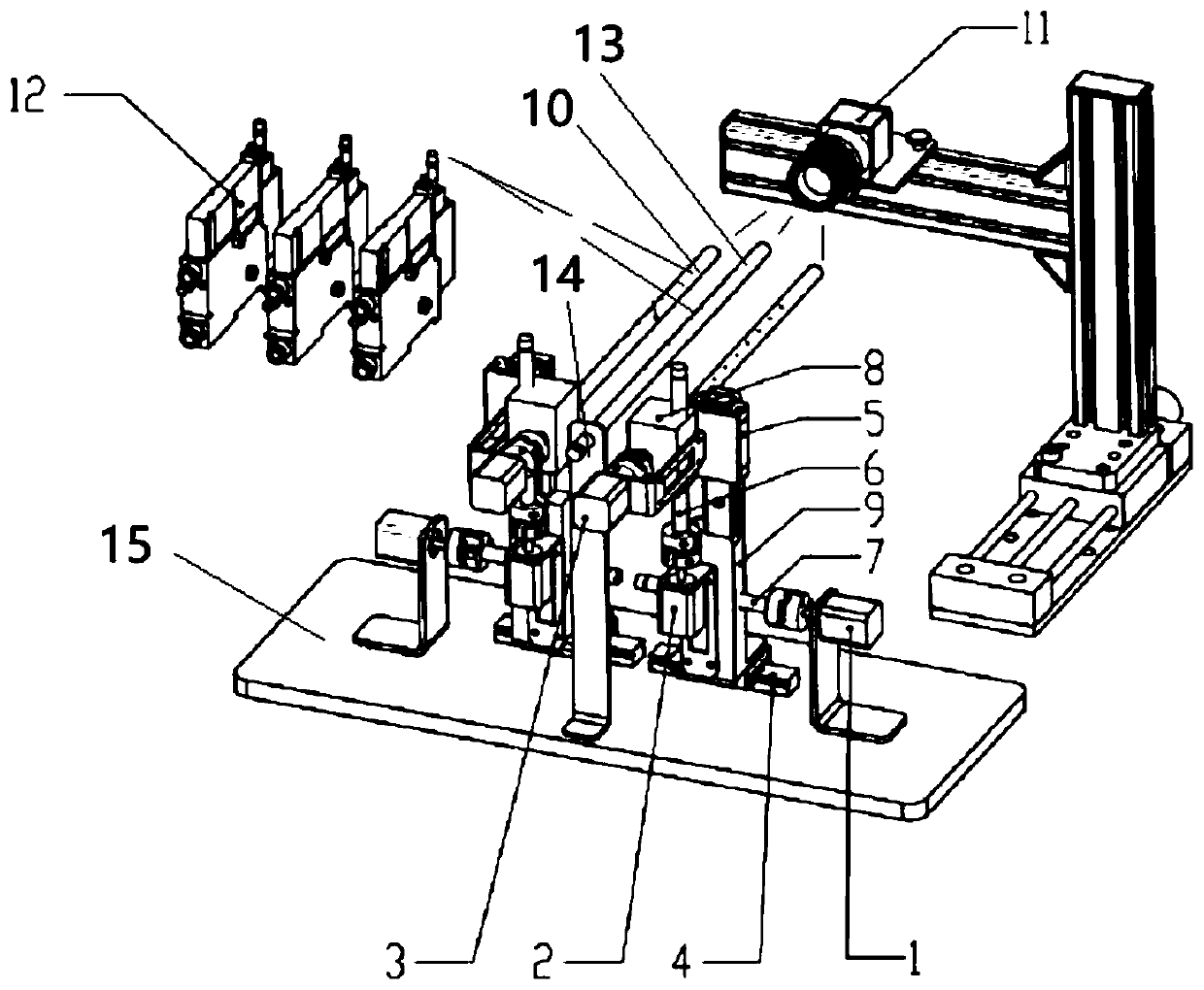

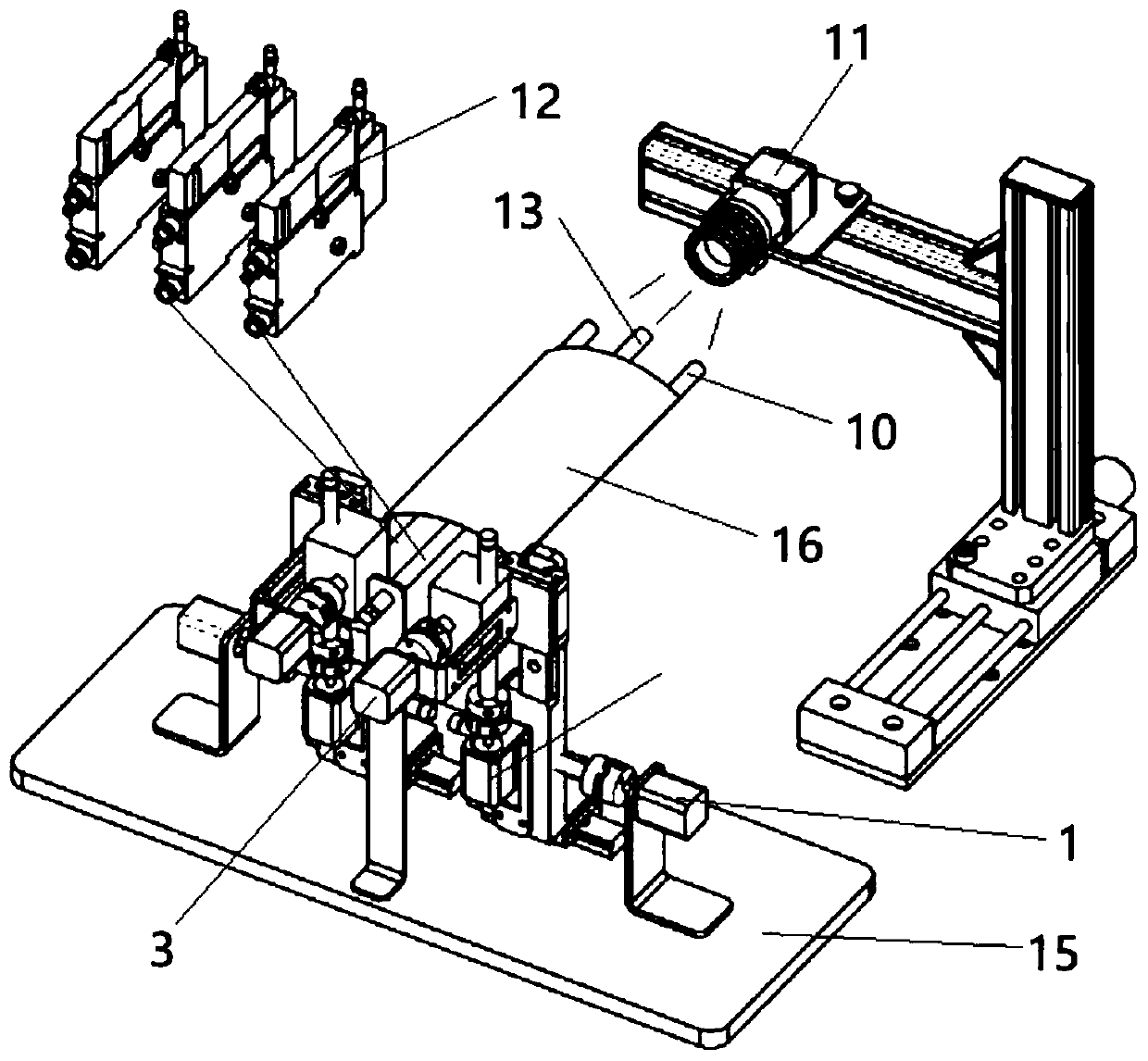

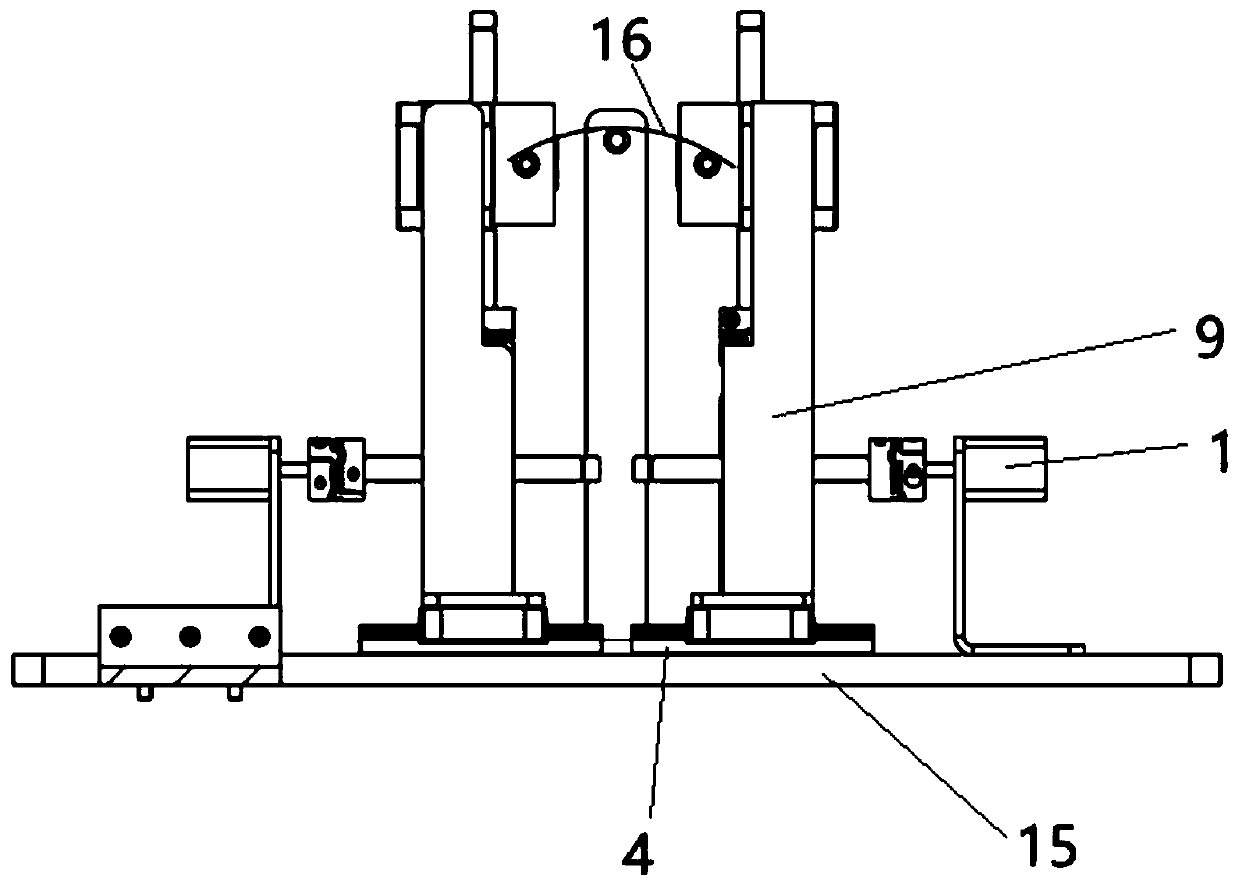

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Figure 1-3 , including X-axis motor 1, Y-axis motor 2, Z-axis motor 3, X-axis moving rail 4, Y-axis moving rail 5, Y-axis moving screw 6, X-axis moving screw 7, Y-axis moving block 8, X-axis moving block 9, lateral trachea 10, high-speed camera 11, vacuum generator module 12, median trachea 13, median ventilation tube installation frame 14, working surface 15, film 16, etc.

[0020] Such as figure 1 As shown, the present invention is a film shape control device based on visual camera detection technology, including a median trachea 13, and the median trachea 13 is horizontally arranged above the workbench 15 through a median ventilation tube installation frame 14. The median trachea 13 There is a small hole for the median ventilator on the top, and the small hole for the median ventilator is located at the top of the median trachea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com