Multi-core plastic optical fibers and plastic optical fiber cable

A technology for plastic optical fibers and optical cables, applied in the directions of light guides, optics, optical components, etc., can solve the problems of difficulty in further reducing the cost, difficult to increase the transmission rate, messy wiring, etc., and achieve the effect of low installation cost, large bending radius, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] An embodiment of the multi-core plastic optical fiber provided by the present invention is as follows:

[0041] A multi-core plastic optical fiber includes a solid cladding, a plurality of plastic optical fiber cores and a mark for identifying the relative position of the plastic optical fiber core. The refractive index of the cladding is less than that of the plastic optical fiber core. All plastic optical fiber cores are located inside the cladding, extend radially along the cladding, and penetrate the cladding. The distance between the cores of the plastic optical fiber is between 2um and 20000um, identification mark Extend parallel to the plastic optical fiber core.

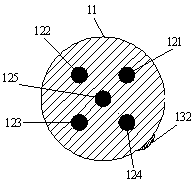

[0042] Another embodiment of the multi-core plastic optical fiber provided by the present invention is as follows:

[0043] A multi-core plastic optical fiber includes a cladding, a plurality of plastic optical fiber cores, a plurality of hollow holes and a mark for identifying the relative position of the ...

Embodiment approach

[0053] An embodiment of the plastic optical fiber optical cable provided by the present invention is:

[0054] A plastic optical fiber cable, including one or more cable cores, one or more sheaths and a sheath. All cable cores and sheaths are in a one-to-one correspondence. Each cable core and the corresponding sheath form one Concentric cable, that is, the periphery of the cable core is surrounded by a sheath, and all the sheaths are circumferentially distributed in the outer sheath, that is, the outer sheath radially surrounds all the sheaths and the inner cable core, forming a cylindrical multi-core optical cable. In the specific implementation of this solution, a protective layer can be added between the cable core and the sheath, and the cable core can be a multi-core plastic optical fiber.

[0055] In the above embodiment, when the number of cable cores is one, the outer sheath and the sheath are combined into one, that is, the plastic optical fiber cable only includes a cabl...

Embodiment 1

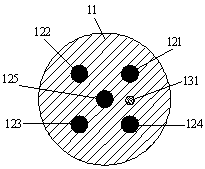

[0062] Embodiment 1: A five-core plastic optical fiber.

[0063] figure 2 Shown is a five-core plastic optical fiber, which includes a cladding 11, plastic optical fiber cores 121-125, and a colored marking core 131. In this embodiment, the cladding 11 is a solid structure, and the plastic optical fiber cores 121 to 125 and the colored marking core wires 131 are enclosed in the cladding 11. The cladding 11 combines the plastic optical fiber cores 121 to 125 and the colored marking core wires 131 package. The four plastic optical fiber cores 121 to 124 of the five-core plastic optical fiber shown in this embodiment are located on the four vertices of an imaginary square that coincides with the center of the cladding, and the fifth plastic optical fiber core 125 is located on the plastic optical fiber core 121 to At the center of 124, the colored marking core wire 131 is located in the middle of the plastic optical fiber cores 121 and 124. In this embodiment, the materials of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com