System and method for realizing material allocation integration based on ERP (Enterprise Resource Planning) system

An ERP system and material technology, applied in manufacturing computing systems, logistics, office automation, etc., can solve problems affecting the timely delivery of orders, affect the work efficiency of multiple departments, and the progress of material allocation is not intuitive, so as to improve the timely delivery and , Realize the effect of timely delivery and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

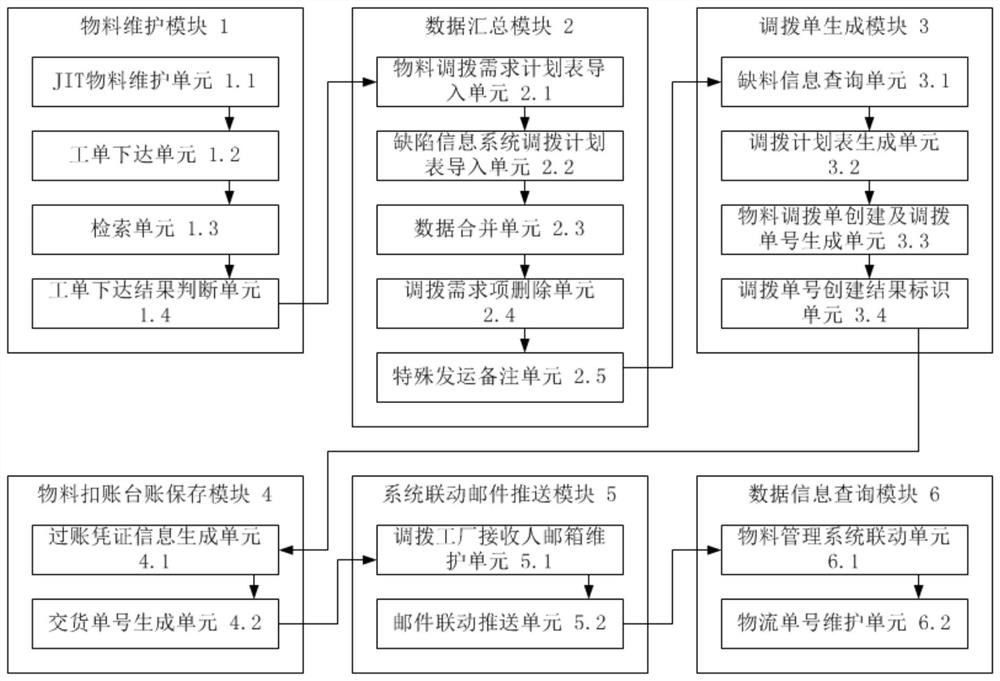

[0085] Such as figure 1 As shown, the present invention provides a system based on the ERP system to realize the integration of material allocation, including:

[0086] Material maintenance module 1 is used to maintain JIT materials. According to the APO work order requirements, retrieve the BOM material information of the work order to judge whether the materials are complete, and create and release the APO work order when the materials are complete, and when the materials are missing, Identify the material shortage information, and send the material shortage information to the material allocation demand plan;

[0087] Data summary module 2, which is used to summarize the material allocation demand schedule and the imported allocation schedule of the material shortage information system, and merge the quantities of the same PN materials in the material shortage information;

[0088] The transfer order generation module 3 is used to retrieve factory inventory and storage loca...

Embodiment 2

[0093] Such as figure 1 As shown, the present invention provides a system based on the ERP system to realize the integration of material allocation, including:

[0094] Material maintenance module 1 is used to maintain JIT materials. According to the APO work order requirements, retrieve the BOM material information of the work order to judge whether the materials are complete, and create and release the APO work order when the materials are complete, and when the materials are missing, Identify material shortage information and send the material shortage information to the material allocation demand plan; material maintenance module 1 includes:

[0095] JIT material maintenance unit 1.1, used to create transaction codes and maintain JIT materials in the ERP system;

[0096] The work order release unit 1.2 is used to release the APO work order according to the requirements of the APO work order;

[0097] Retrieval unit 1.3 is used to automatically retrieve the work order BOM m...

Embodiment 3

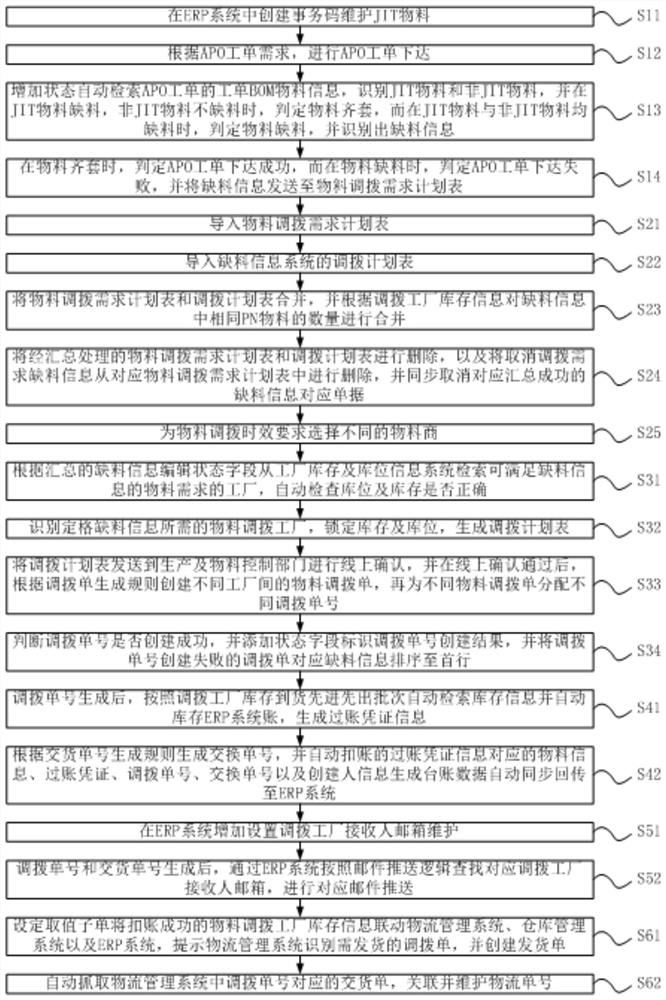

[0120] Such as figure 2 As shown, the present invention provides a method for realizing the integration of material allocation based on the ERP system, comprising the following steps:

[0121] S 1. Maintain JIT materials, retrieve the BOM material information of the work order to determine whether the materials are complete according to the APO work order requirements, and create and issue the APO work order when the materials are complete, and identify the lack of material information when the material is missing , and send the material shortage information to the material allocation demand schedule;

[0122] S2. Summarize the material allocation demand schedule and the imported allocation schedule of the material shortage information system, and merge the quantities of the same PN materials in the material shortage information;

[0123] S3. Retrieve factory inventory and location information The system searches for factories that can meet the material demand for material s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com