Intelligent detection system and method for looseness and fracture of bolts of wind driven generator

A technology for wind turbines and bolt loosening, which is applied in wind turbines, monitoring of wind turbines, and wind power generation. Single bolt detection method and other problems, to achieve the effect of easy procurement, high sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with specific embodiment the present invention is described in further detail, described is explanation of the present invention rather than limitation.

[0061] The present invention can solve the problem of non-intelligent detection of bolt looseness and fracture in existing wind turbines, and provides a more comprehensive and intelligent detection system for looseness and fracture of wind turbine bolts, which can replace manual methods, avoid existing problems in existing detection, and improve work efficiency.

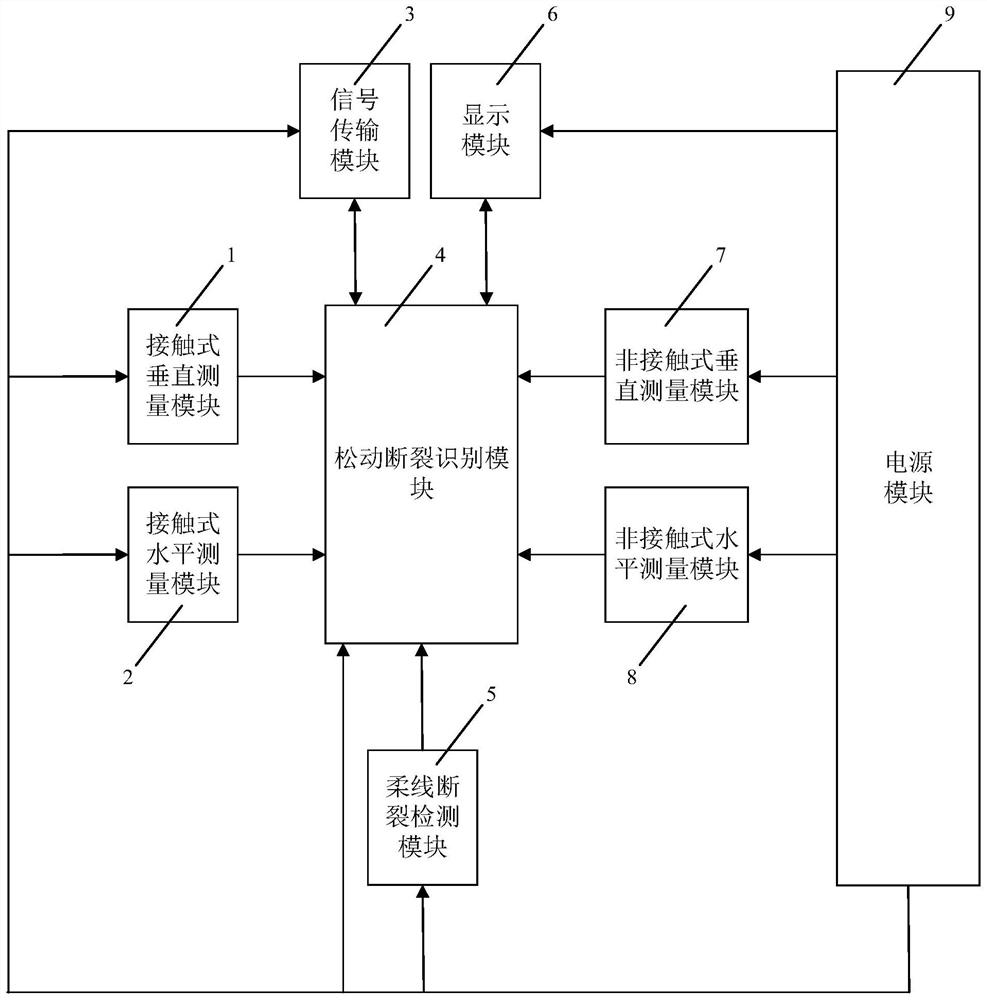

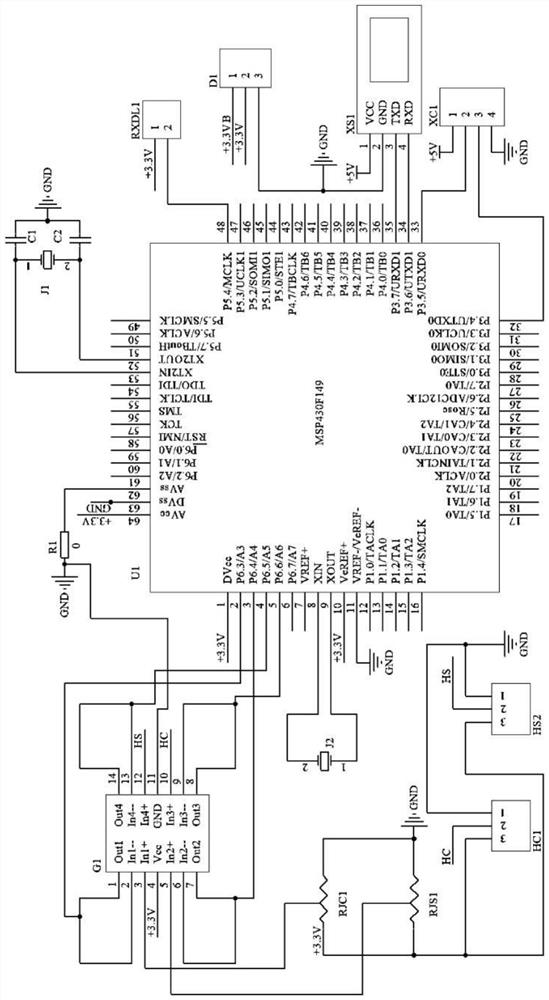

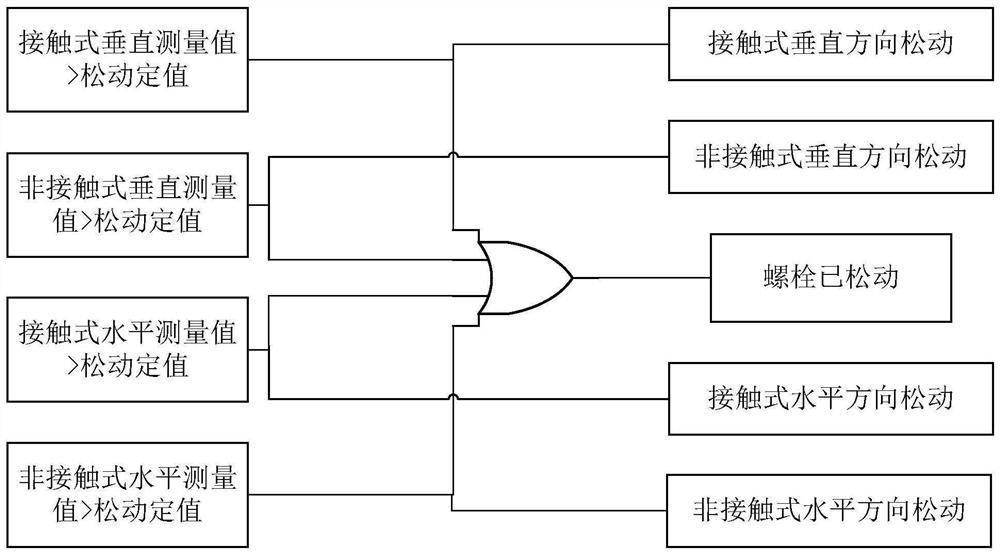

[0062] The present invention is an intelligent detection system for loosening and fracture of wind turbine bolts, such as figure 1 As shown, it includes a contact vertical measurement module 1, a contact horizontal measurement module 2, a signal transmission module 3, a loose fracture identification module 4, a flexible line fracture detection module 5, a display module 6, a non-contact vertical measurement module 7 and a non-contact Ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com