Tunnel karst fracture zone slip collapse half-section curtain advancing type grouting reinforcement treatment method

A technology of grouting reinforcement and processing method, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as lack of construction case guidance, affect the construction period of the whole line, increase material waste, etc., so as to ensure the effect of grouting reinforcement and speed up construction The effect of processing progress and reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

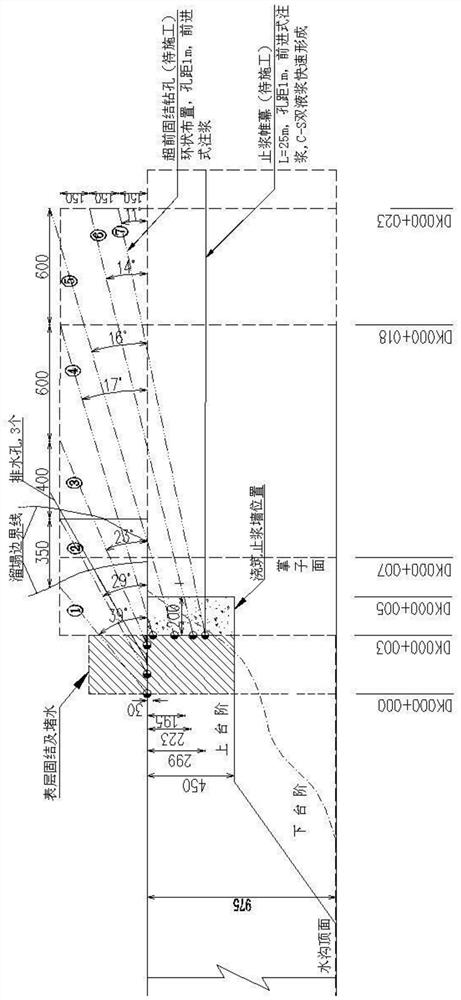

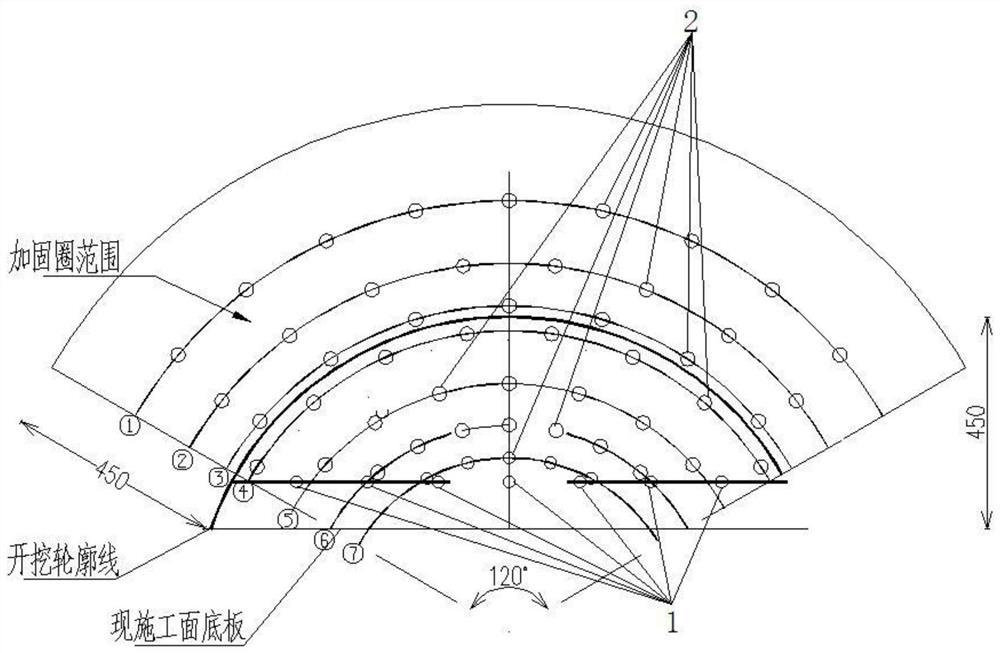

[0024] As shown in the attached figure, the unfavorable geology of this construction case is a karst fracture zone, mainly composed of dolomite and dolomitic limestone interbedded with marl, with extremely well-developed joints and fissures in the form of fragmentation and looseness, and the surrounding rock is broken to extremely broken; Small dissolution pores are seen in the rock, the dissolution is relatively developed, and the karst fissure water is developed; the tunnel is excavated to form an empty surface, and the loose vault is affected by the fissure water and collapses, and the maximum water inflow is about 12000m 3 / d, the normal water inflow is about 6000m 3 / d.

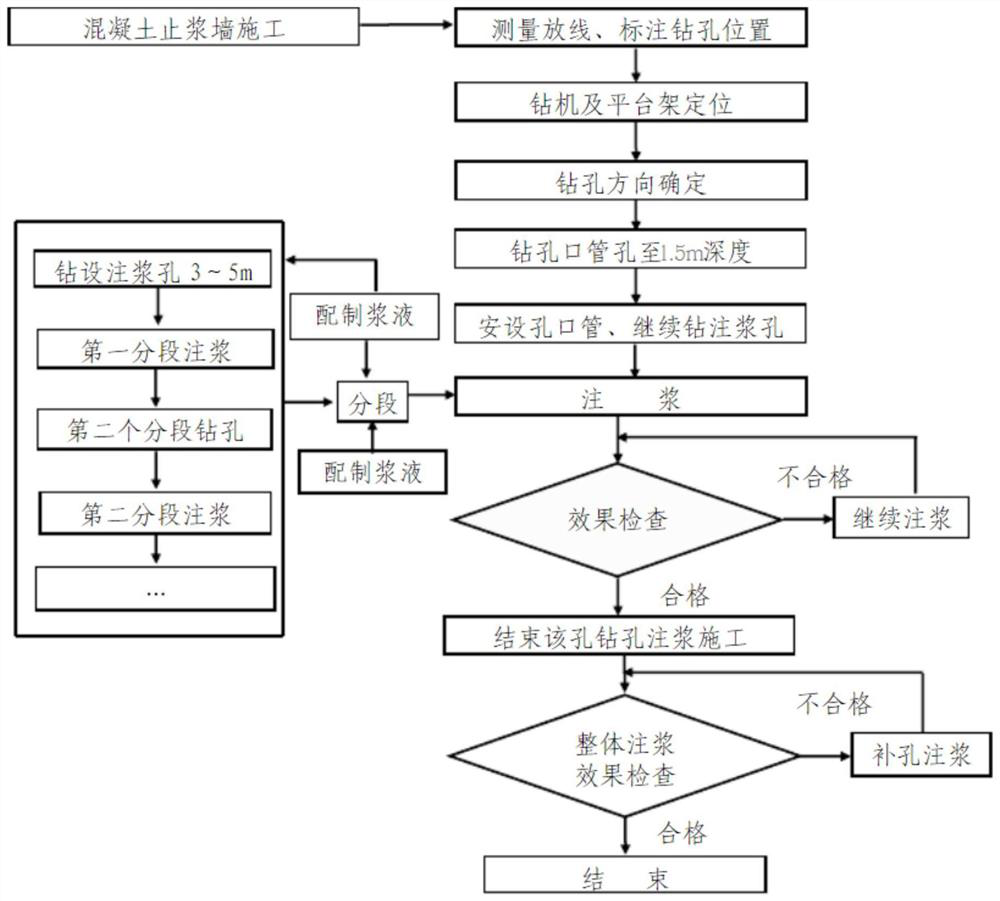

[0025] Main construction procedures and construction steps:

[0026] Emergency backfilling and plugging of the face of the tunnel → grouting consolidation of the slump bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com