Steel bar truss floor bearing hollow composite board and construction method thereof

A steel truss and hollow slab technology, applied in the field of steel truss floor decks, can solve the problems of limited span, mismatched quantity, material waste, etc. of steel truss floor decks, and achieves easy construction quality assurance, light weight, and good economy. The effect of the indicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

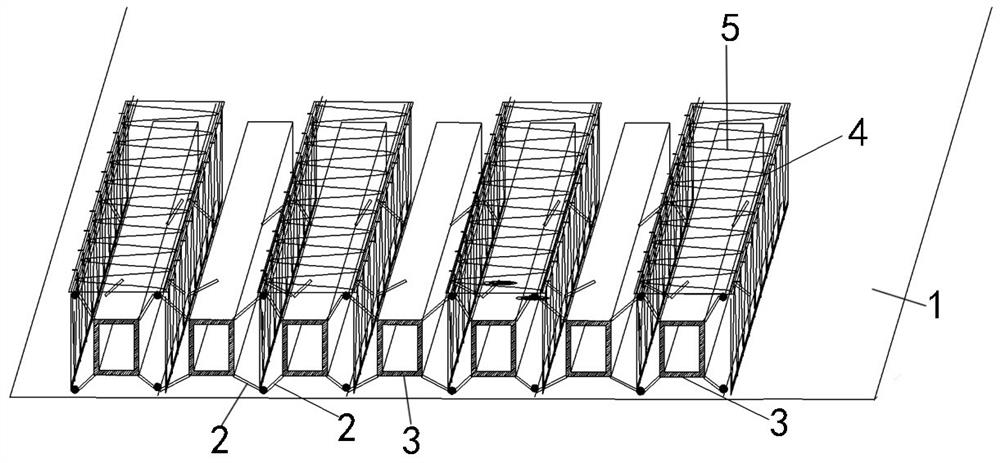

[0047] Example to participate Figure 1-7 As shown, a reinforced truss floor bearing composite hollow slab includes a slab body, and the slab body includes a bottom profiled steel plate 1 , a steel bar composite frame, a hollow formwork 3 and formwork connectors 2 . Bottom profiled steel plate 1 can change and adopt closed type, low wave high pressure type steel plate.

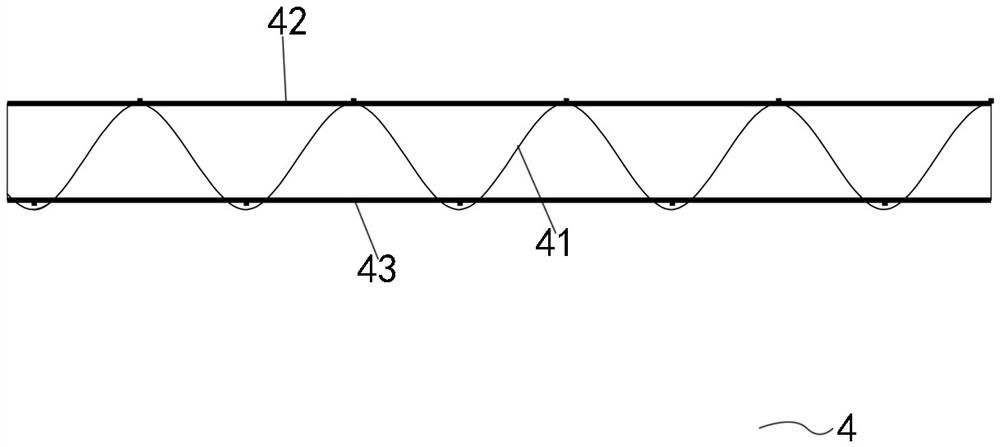

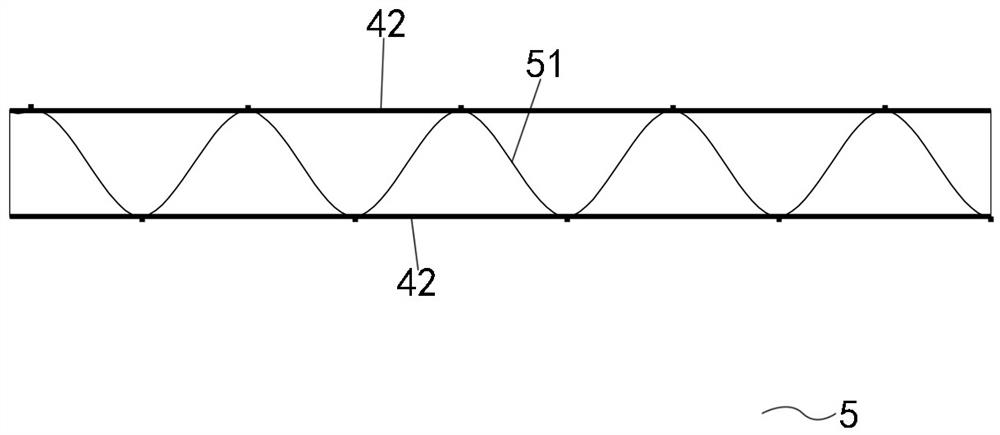

[0048]The steel bar composite frame is arranged along the longitudinal length of the profiled steel plate 1 at the bottom, and is arranged at intervals along the transverse direction. Each steel bar composite frame is formed by three planar trusses, and the cross section is a door-shaped composite frame. The hollow formwork 3 is arranged along the The bottom profiled steel plate 1 is arranged longitudinally and at intervals along the transverse direction, and the hollow formwork 3 includes an inner formwork 31 centrally arranged in the steel bar composite frame and a frame inner formwork 31 arranged in the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com