Finishing process of natural antibacterial medical colored cotton bleached gauze

A technology of colored cotton and gauze, applied in the field of medical gauze, can solve the problems such as the inability of bacteriostatic substances to migrate from the inside and the inability to reflect the bacteriostatic properties of colored cotton fibers, so as to accelerate wound healing, reduce bacterial infection, and achieve high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

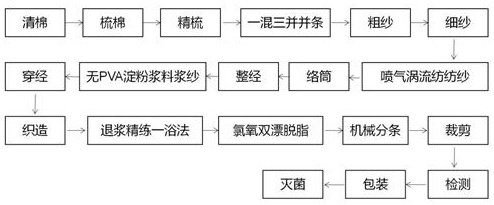

[0022] Process flow of the present invention such as figure 1 As shown, the specific process is described as follows:

[0023] The colored cotton fiber is sequentially subjected to the processes of cleaning, carding, combing, one-mixing and three-drawing, roving, and spun yarn, and the yarn is made by vortex spinning technology, and then the yarn is wound, warped, PVA-free starch sizing, and threaded. It is woven into colored cotton gauze through the weaving and weaving processes.

[0024] The colored cotton gauze is subjected to desizing and refining one-bath treatment. The process formula is: α-amylase 2.5-3g / L, glucose oxidase 2.5-3g / L, cellulase 2.5-3g / L, the original fruit Glue enzyme (PPASE) is 2.5-3g / L, D-limonene is 1-1.5g / L, scouring agent GX-2021 is 1-1.5g / L, bath ratio is 1:15-20, pH value is 7 -8, the scouring temperature is 65-75°C, the scouring time is 60-70min, and bleaching is carried out after washing.

[0025] In this process, the role of α-amylase is to h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com