Aluminum ash-based porous ceramic material and preparation method thereof

A technology of porous ceramics and aluminum ash, which is applied in the preparation of porous ceramic materials and the field of porous ceramic materials, can solve the problems of unreasonable disposal and utilization of residues, and achieve the effect of reasonable design, avoiding toxic and dangerous gases, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

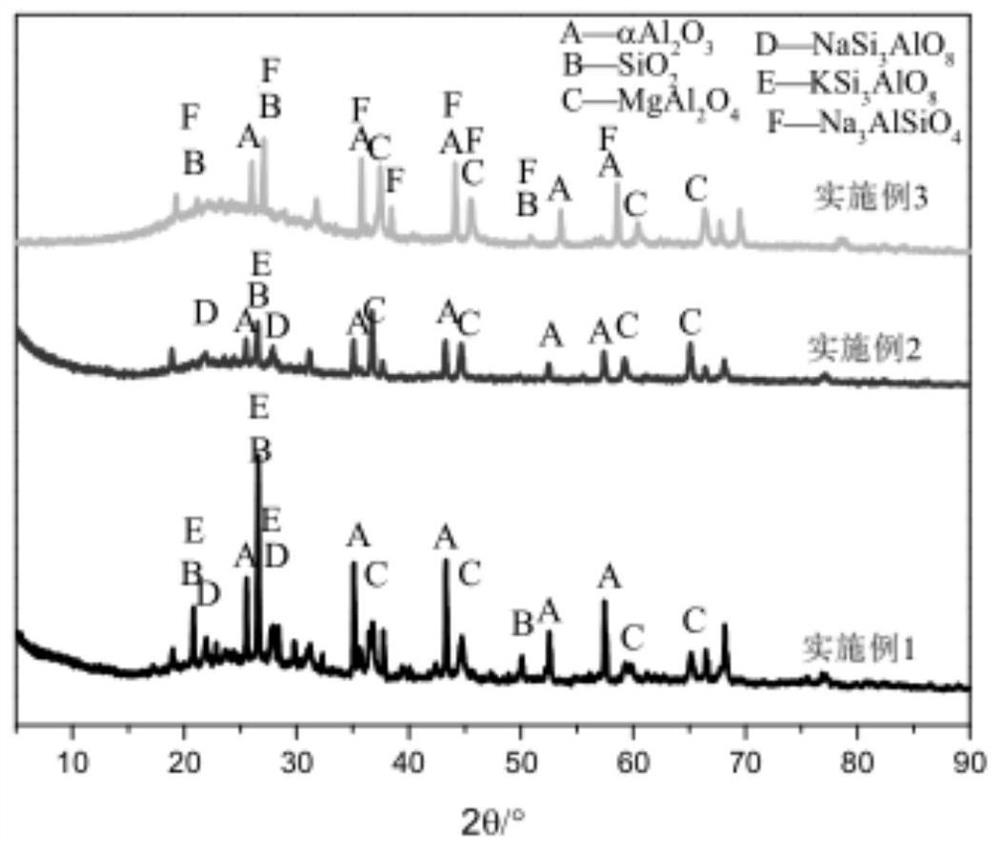

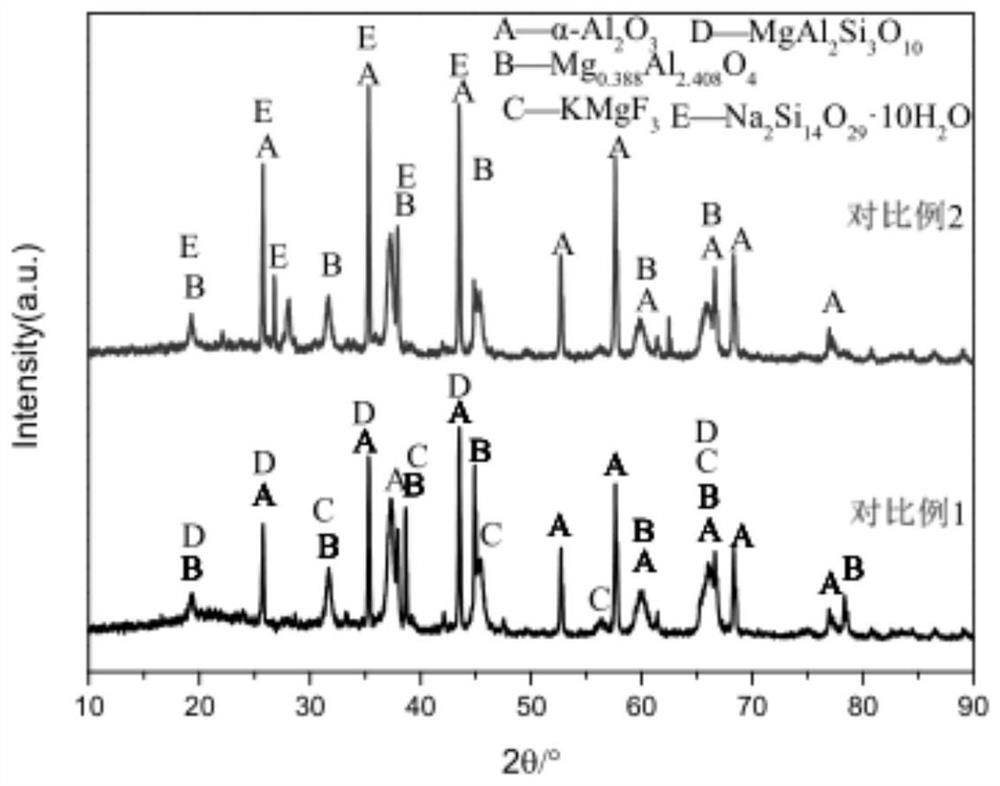

Embodiment 1

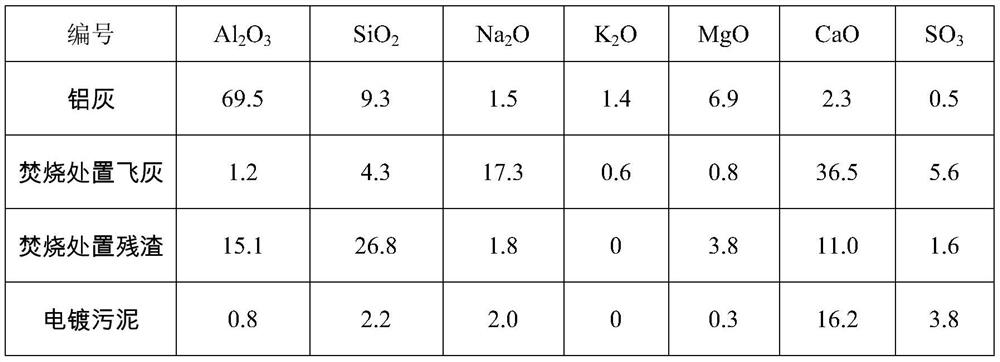

[0037] Aluminum ash, incineration and disposal of fly ash, incineration and disposal of slag, electroplating sludge, and other solid waste (waste glass) in the proportion of 25wt%, 10wt%, 12wt%, 6wt%, 47wt% (based on the solid matter after drying , the main chemical composition of hazardous waste raw materials is shown in Table 1), mixed with 5% waste mineral oil, put it into a ball mill, and ball milled for 20 minutes according to the ball-to-material ratio of 4:1. Die-cast the powder obtained by grinding at a die-casting strength of 7 MPa and a die-casting time of 3 minutes. Put the formed blank into a high-temperature furnace, raise the temperature to 1000°C at a heating rate of 8°C / min, and then raise the temperature to 1150°C at a rate of 5°C / min, and after firing for 30 minutes, cool it to room temperature at 10°C / min to obtain aluminum ash based porous ceramic materials.

[0038] Table 1 Main chemical composition of hazardous waste raw materials

[0039]

[0040] ...

Embodiment 2

[0046] The components of aluminum ash, incineration fly ash, incineration slag and electroplating sludge refer to Example 1.

[0047] Aluminum ash, incineration and disposal of fly ash, incineration and disposal of slag, electroplating sludge, and other solid waste (waste glass) in proportions of 35wt%, 15wt%, 15wt%, 5wt%, and 30wt% (based on the solid matter after drying) ), mixed with 6% waste mineral oil, put it into a ball mill, and ball milled for 15 minutes according to the ball-to-material ratio of 5:1. Die-cast the powder obtained by grinding at a die-casting strength of 6 MPa and a die-casting time of 2 min. Put the formed blank into a high-temperature furnace, raise the temperature to 1000°C at a heating rate of 10°C / min, then raise the temperature to 1180°C at a rate of 5°C / min, and cool to room temperature at 20°C / min after firing for 40 minutes to obtain an aluminum ash base porous ceramic material.

[0048] The volume expansion of the fired aluminum ash-based p...

Embodiment 3

[0053] The components of aluminum ash, incineration fly ash, incineration slag and electroplating sludge refer to Example 1.

[0054] Aluminum ash, incineration fly ash, incineration slag, electroplating sludge, and other solid waste (waste glass) are 40wt%, 20wt%, 20wt%, 5wt%, 15wt% (based on the solid matter after drying), Put 6% waste mineral oil into the ball mill, and ball mill for 10 minutes according to the ball-to-material ratio of 6:1. Die-cast the powder obtained by grinding at a die-casting strength of 5 MPa and a die-casting time of 2 min. Put the formed blank into a high-temperature furnace, raise the temperature to 1000°C at a heating rate of 15°C / min, then raise the temperature to 1150°C at a rate of 3°C / min, and cool to room temperature at 30°C / min after firing for 60 minutes to obtain aluminum ash base porous ceramic material.

[0055] The volume expansion of the fired aluminum ash-based porous ceramic material is remarkable, and its section has a uniform an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com