Intelligent driving drive-by-wire chassis

A technology of intelligent driving and chassis, applied in the direction of circuit or fluid pipeline, substructure, transportation and packaging, etc., can solve the problems of unfavorable maintenance, inconvenient cable combing, and disordered cables, etc., to achieve convenient maintenance, convenient combing, The effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

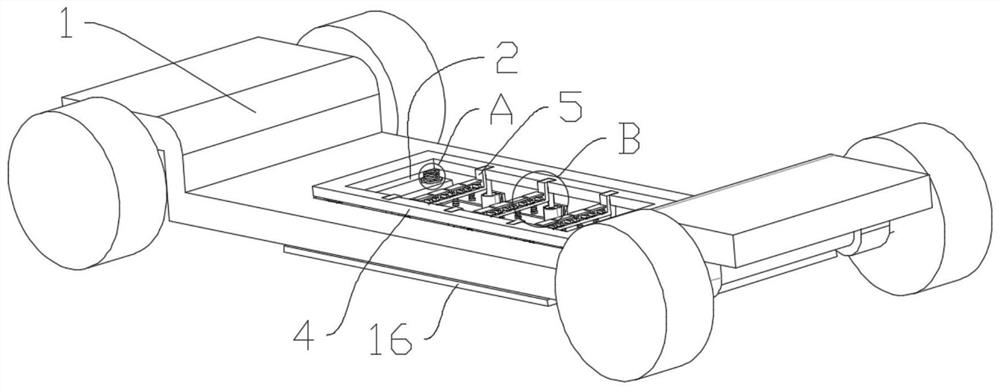

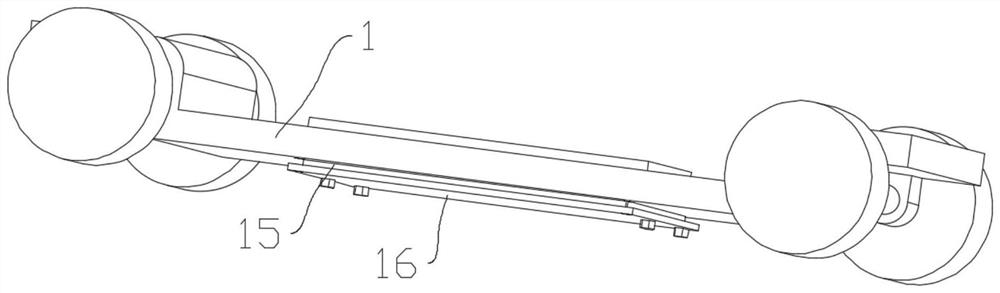

[0033] refer to Figure 1-Figure 4 , an intelligent drive-by-wire chassis, comprising a chassis body 1, a stepped groove 2 is arranged on one side of the chassis body 1, a buffer mechanism 3 is arranged on the stepped groove 2, an installation frame 4 is installed on the buffer mechanism 3, and an installation frame 4 is installed on the installation frame 4 A plurality of equidistantly distributed wire harness plates 5 are provided, on which a number of sliding rods 6 are slidably installed, and a number of wire retaining plates 7 are installed on the slider rods 6, and the distance between the slide rods 6 and the wire harness plates 5 is fixedly installed. There is a first spring 8, and both sides of the wire retaining plate 7 are provided with clamping blocks 9.

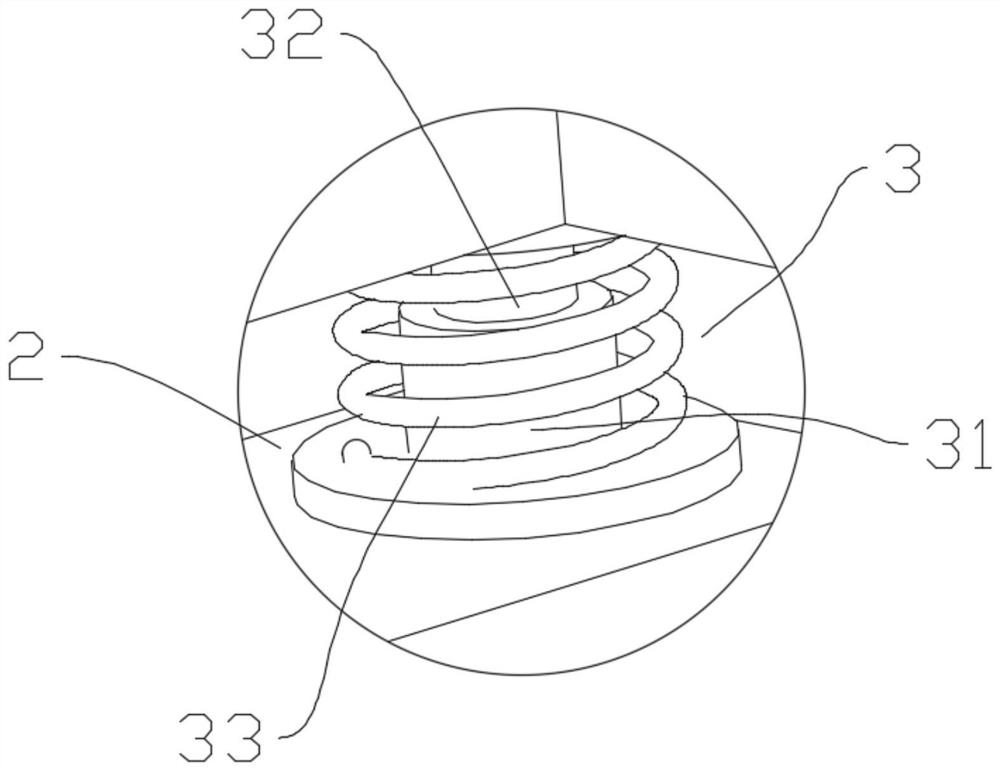

[0034] refer to image 3 , the buffer mechanism 3 includes a first buffer rod 31, a second buffer rod 32 and a second spring 33, the first buffer rod 31 is installed on the stepped groove 2, the second buffer ro...

Embodiment 2

[0041] refer to Figure 1-Figure 4, an intelligent drive-by-wire chassis, comprising a chassis body 1, a stepped groove 2 is arranged on one side of the chassis body 1, a buffer mechanism 3 is arranged on the stepped groove 2, an installation frame 4 is installed on the buffer mechanism 3, and an installation frame 4 is installed on the installation frame 4 A plurality of equidistantly distributed wire harness plates 5 are provided, on which a number of sliding rods 6 are slidably installed, and a number of wire retaining plates 7 are installed on the slider rods 6, and the distance between the slide rods 6 and the wire harness plates 5 is fixedly installed. There is a first spring 8, and both sides of the wire retaining plate 7 are provided with clamping blocks 9.

[0042] refer to figure 2 , the buffer mechanism 3 includes a first buffer rod 31, a second buffer rod 32 and a second spring 33, the first buffer rod 31 is installed on the stepped groove 2, the second buffer ro...

Embodiment 3

[0048] refer to Figure 1-Figure 4 , an intelligent drive-by-wire chassis, comprising a chassis body 1, a stepped groove 2 is arranged on one side of the chassis body 1, a buffer mechanism 3 is arranged on the stepped groove 2, an installation frame 4 is installed on the buffer mechanism 3, and an installation frame 4 is installed on the installation frame 4 A plurality of equidistantly distributed wire harness plates 5 are provided, on which a number of sliding rods 6 are slidably installed, and a number of wire retaining plates 7 are installed on the slider rods 6, and the distance between the slide rods 6 and the wire harness plates 5 is fixedly installed. There is a first spring 8, and both sides of the wire retaining plate 7 are provided with clamping blocks 9.

[0049] refer to figure 2 , the buffer mechanism 3 includes a first buffer rod 31, a second buffer rod 32 and a second spring 33, the first buffer rod 31 is installed on the stepped groove 2, the second buffer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com