A kind of multidirectional forging method of nickel-rich nickel-titanium intermetallic compound

An intermetallic compound, multi-directional forging technology, applied in metal processing equipment and other directions, can solve the problems affecting the service life of materials and market promotion, material bonding defects, powder oxidation pollution, etc., to reduce stress, solve difficult, organizational problems uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

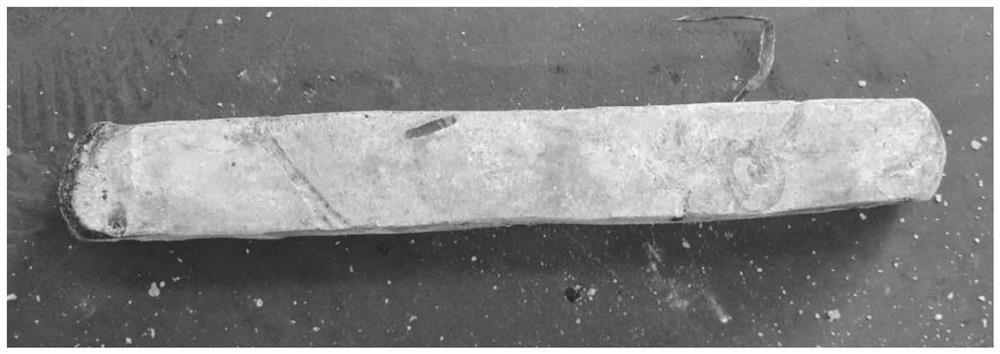

Image

Examples

Embodiment 1

[0022] This embodiment includes the following steps:

[0023] Step 1, coating the surface of a 60NiTi round ingot with a diameter of 160mm with KBC-12 anti-oxidation coating, and then drying and dewatering treatment at 100° C. for 2h; the mass content of Ti in the 60NiTi round ingot is 41.0%;

[0024] Step 2, heating the 60NiTi round ingot after drying and dewatering treatment in step 1 to 1050 °C for 5 hours, then furnace cooling to 800 °C for 5 hours, and then furnace cooling to 400 °C for air cooling;

[0025] Step 3: Coating the surface of the 60NiTi round ingot after air cooling in step 1 with asbestos with a thickness of 1mm, then heating to 1000°C for 160min;

[0026] Step 4: Preheat the hammer head of the hydraulic forging machine to 200° C., then place the 60NiTi round ingot after heating and heat preservation in step 3 in the hydraulic forging machine for upsetting and axial deformation to obtain a 60NiTi billet; The first reduction of upsetting is 8%, the second re...

Embodiment 2

[0030] This embodiment includes the following steps:

[0031] Step 1, coating the surface of a 60NiTi round ingot with a diameter of 100mm with KBC-12 anti-oxidation paint, and then drying and dewatering at 200° C. for 1 hour; the mass content of Ti in the 60NiTi round ingot is 39.0%;

[0032] Step 2, heating the 60NiTi round ingot after drying and dewatering treatment in step 1 to 900 °C for 8 hours, then furnace cooling to 800 °C for 4 hours, and then furnace cooling to 450 °C for air cooling;

[0033] Step 3: Coating the surface of the 60NiTi round ingot with air cooling in step 1 with asbestos with a thickness of 2mm, then heating to 950°C for 100min;

[0034] Step 4: Preheat the hammer head of the hydraulic forging machine to 300° C., then place the 60NiTi round ingot after heating and heat preservation in step 3 in the hydraulic forging machine for upsetting and axial deformation to obtain a 60NiTi billet; The first reduction of upsetting is 10%, the second reduction is...

Embodiment 3

[0038] This embodiment includes the following steps:

[0039] Step 1. Coat the surface of the 60NiTiHf raw material bar with a side length of 70 mm with KBC-12 anti-oxidation coating, and then perform drying and dewatering treatment at 150 ° C for 1.5 hours; the mass content of Ni in the 60NiTiHf raw material bar is 56.0 %, the mass content of Hf is 10.0%;

[0040] Step 2, heating the 60NiTiHf raw material bar after drying and dewatering treatment in step 1 to 930°C for 10h, then furnace cooling to 800°C for 2h, and then furnace cooling to 350°C for air cooling;

[0041] Step 3: Coating the surface of the 60NiTiHf raw material bar with a thickness of 3mm after being air-cooled in step 1, and then heating it to 900°C for 70min;

[0042] Step 4: Preheat the hammer head of the hydraulic forging machine to 350°C, and then place the 60NiTiHf raw material bar after heating and heat preservation in step 3 in the hydraulic forging machine for upsetting and axial deformation to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com