Method for sectional treatment of ammonia-containing waste gas

A segmented, waste gas technology, applied in separation methods, gas treatment, combustion methods, etc., can solve the problems of incomplete waste gas treatment and inability to treat polluted gas, and achieve the goal of improving purification effect, prolonging residence time, and improving filtration effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

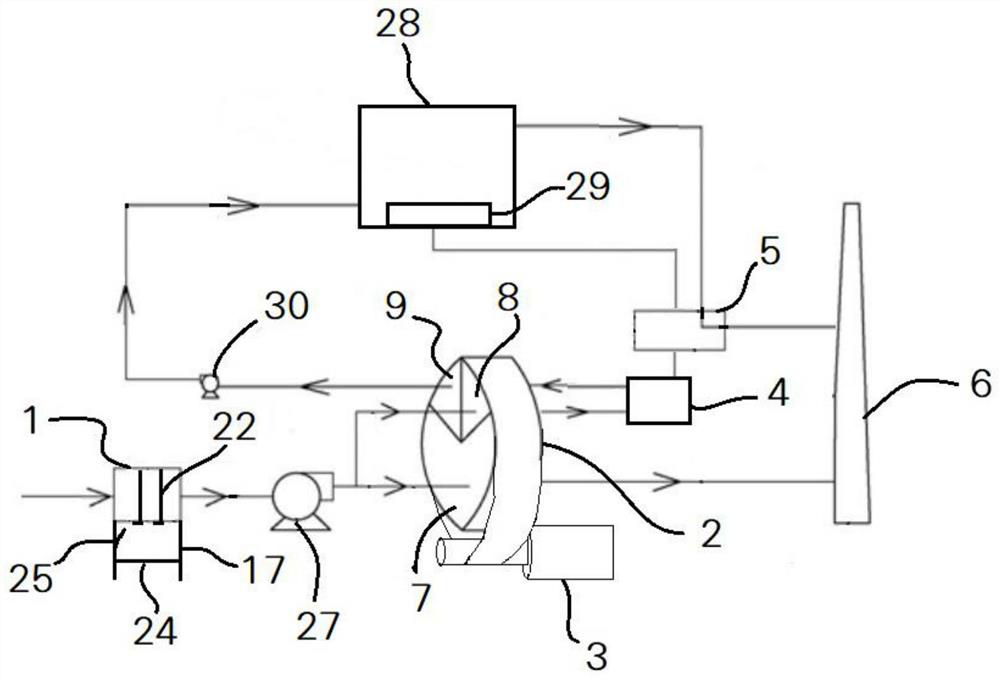

[0039] A method for segmented treatment of ammonia-containing waste gas, comprising the following steps:

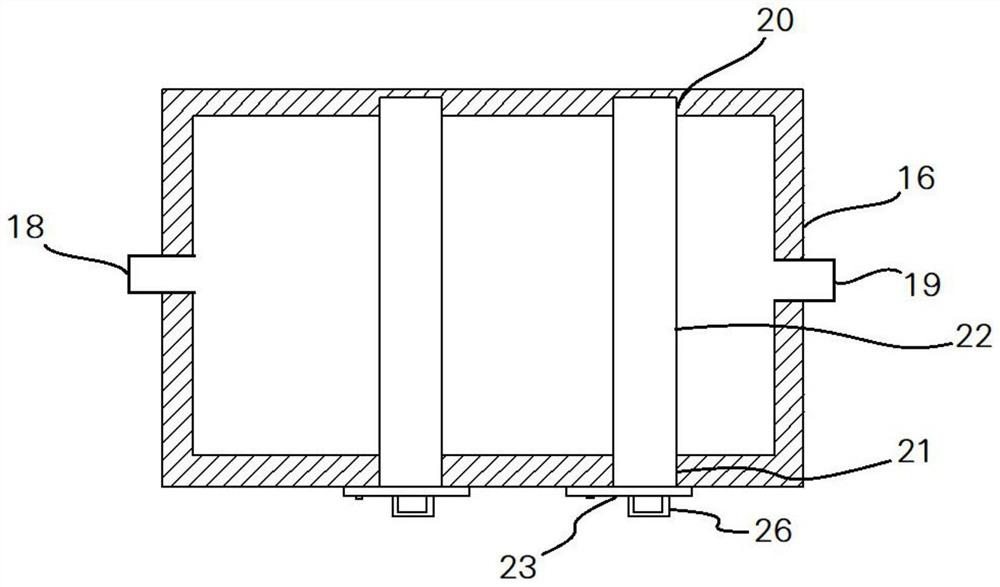

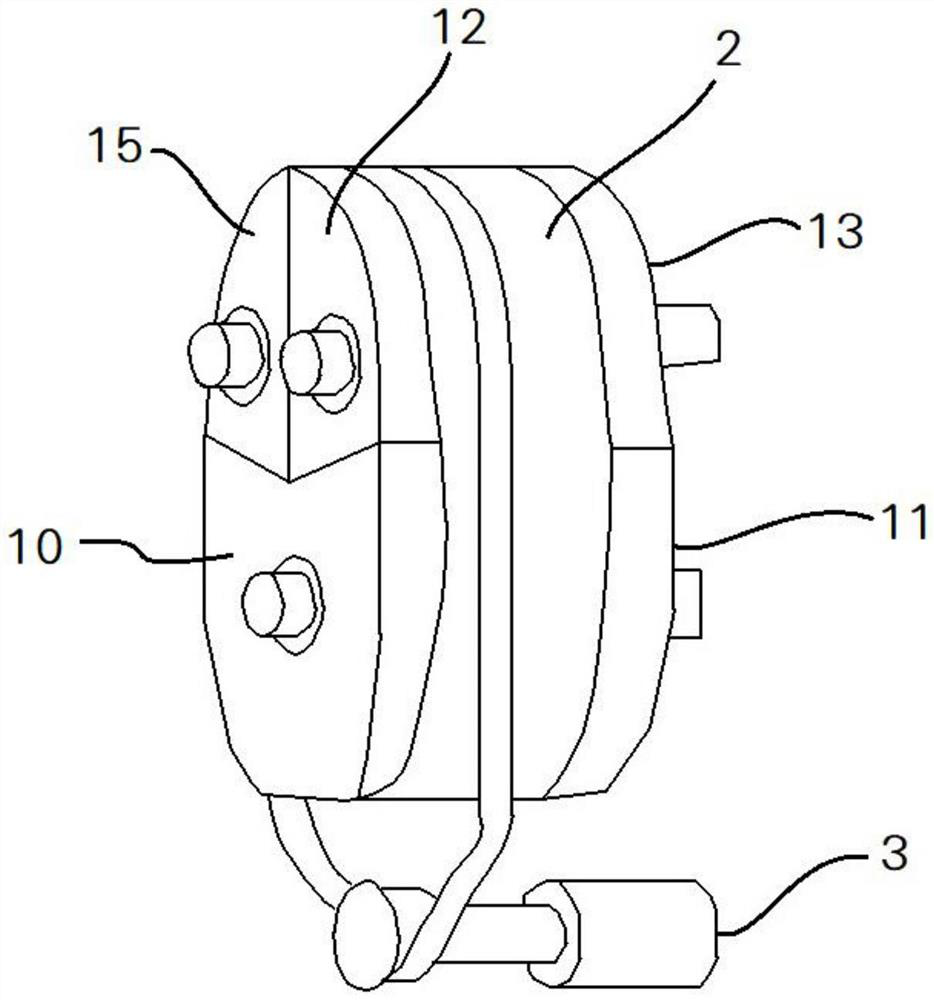

[0040] A, pre-filter treatment: pass ammonia-containing waste gas into the pre-filter device 1 for pre-filter treatment; the pre-filter device 1 includes a box body 16, a support frame 17, a filter plate assembly, a tray 24, and a water gun 25; The box body 16 is set on the support frame 17, the left side of the box body 16 is provided with an air inlet I18, and the right side is provided with an air outlet I19; the filter plate assembly includes a card slot 20, a slot 21, a filter plate 22. Card 23, pull ring 26; the card slot 20 is located at the top of the box body 16; the slot 21 is located at the bottom of the box body 16 and corresponds to the card slot 20; the filter plate 22 Insert the box body 16 from the slot 21, insert its upper end into the card slot 20, and its lower end surface is flush with the bottom of the box body 16; , the card 23 can rotate based on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com