Ester-flavor mould cheese and preparation method thereof

A technology of ester fragrant mold and cheese, which is applied in the field of cheese product preparation, can solve the problems of long production cycle, etc., and achieve the effect of improving rough texture, soft and dense texture, and easy control of fermentation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

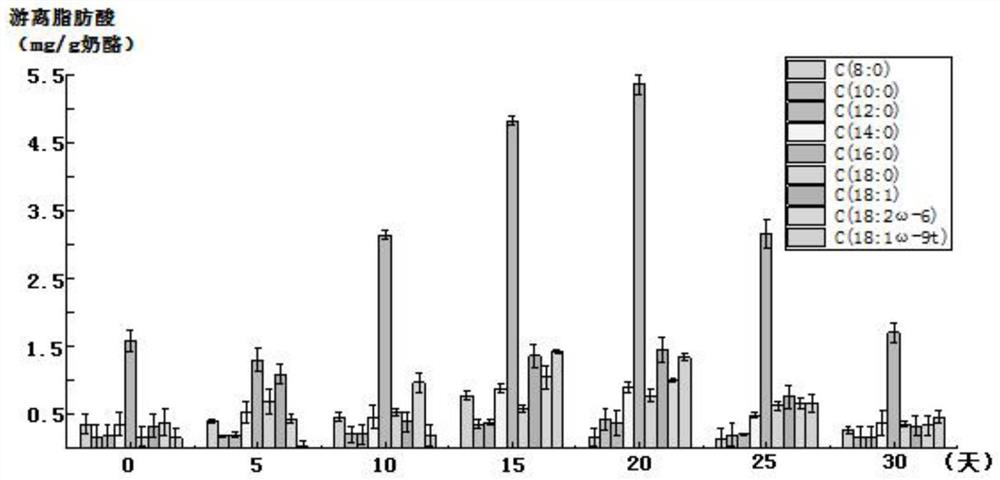

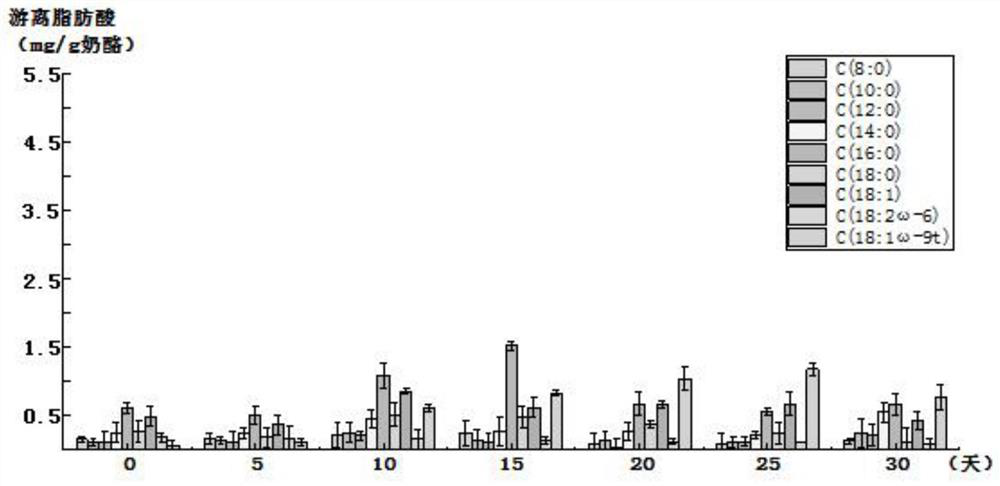

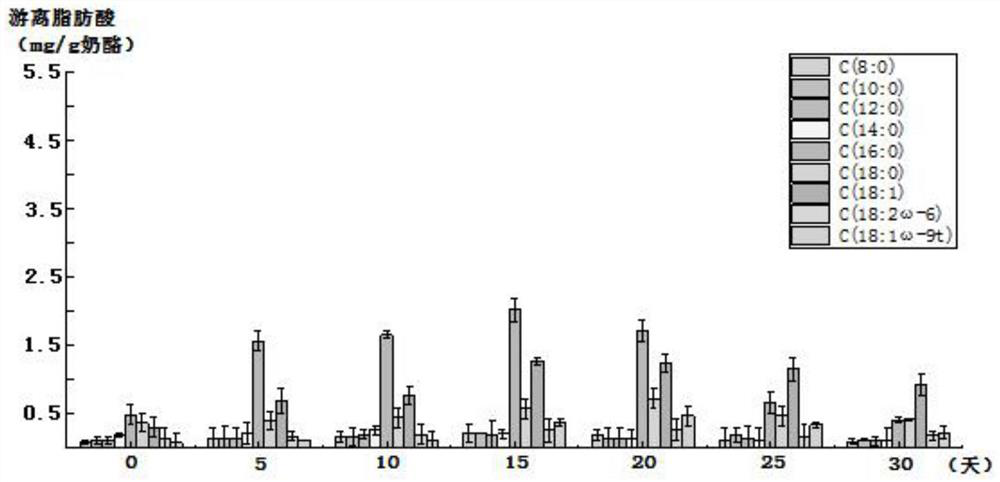

Image

Examples

Embodiment 1

[0037] A ester Fragile Macro, is prepared according to the following steps:

[0038] (1) Preparation of raw materials: 100ml of fresh milk was sterilized at 75 ° C for 15 s, cooled to 37 ° C;

[0039] (2) Add 3% white sugar by mass of fresh milk, stir well;

[0040] (3) Add 1.5% lactic acid bacteria fermentation agent, stir well, fermentation of 1.5 h at 37 ° C;

[0041] (4) Add 0.02% saturated CaCl 2 Aqueous solution, mix well;

[0042] (5) Sequentially adding alcohol yeast suspension and producing yeast suspension, and paste the yeast and the fragrant yeast are inoculated by mass ratio of 2: 1, and the total inoculation amount of the two is 0.6%, stirred evenly;

[0043] Among them, the yield yeast suspension and the fragrant yeast suspension are cultured in liquid YPD medium after passing into liquid YPD medium, at 28-30 ° C, 180 rpm in fluid YPD medium, 180 rpm in liquid YPD medium. 24h, repeated cleaning of the resulting bacterial suspension was repeatedly cleaned and adjuste...

Embodiment 2

[0056] A esteric bacteria cheese, different from Example 1 lies in the amount of yeast after the activation of 0.3%, and the yield yeast is composed of 1: 1 mass than 1: 1 mass.

Embodiment 3

[0058] A esteric bacteria cheese, different from Example 1 lies in the amount of yeast after activation at the time of preparation of 1.5%, and the wine yeast and the fragrant yeast are composed of 1: 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com