Rock drillability evaluation method based on rock debris nanoindentation

A technology of nano-indentation and evaluation method, which is applied in the direction of strength characteristics, test material hardness, instruments, etc., and can solve problems such as difficult to reflect the actual effect, not a constant, and high cost of downhole coring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementations of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific implementation manners described herein are only used to illustrate and explain the embodiments of the present invention, and are not used to limit the embodiments of the present invention.

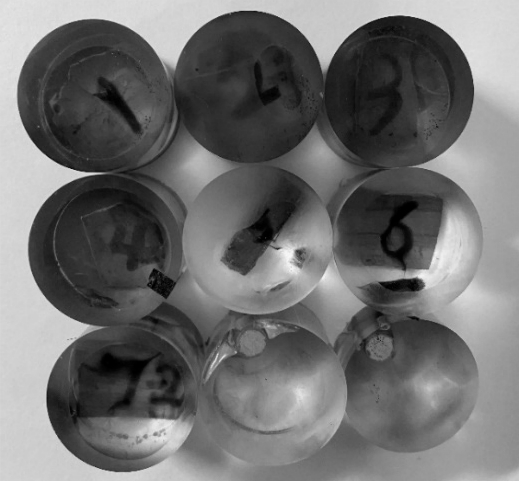

[0055] S11. Collect the target rock cuttings, grind the cuttings to the size of the mold, and test the diameter of the rock sample Φ h image 3 shown;

[0056] S12. Insert the treated cuttings into the mold, inject epoxy resin to make it fully contact with the cuttings, and let it stand for more than 24 hours. After the epoxy resin is completely consolidated, a cemented sample is obtained, and the surface of the test sample is cleaned with an organic solvent. And do drying treatment, sealed and stored after drying;

[0057] S13, demoulding the cemented rock chip sample, use a polishing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com