Boiler thermal efficiency online calculation method of household garbage incineration boiler

A technology for domestic waste incineration and boiler thermal efficiency, which is applied in the directions of calculation, computer-aided design, design optimization/simulation, etc., can solve the problem of inability to accurately obtain the thermal efficiency of domestic waste incineration boilers with external steam-air preheaters in real time, etc. Achieve the effect of improving the level of domestic waste resource utilization, improving the offline and intermittent situation, and promoting the unification of safety and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

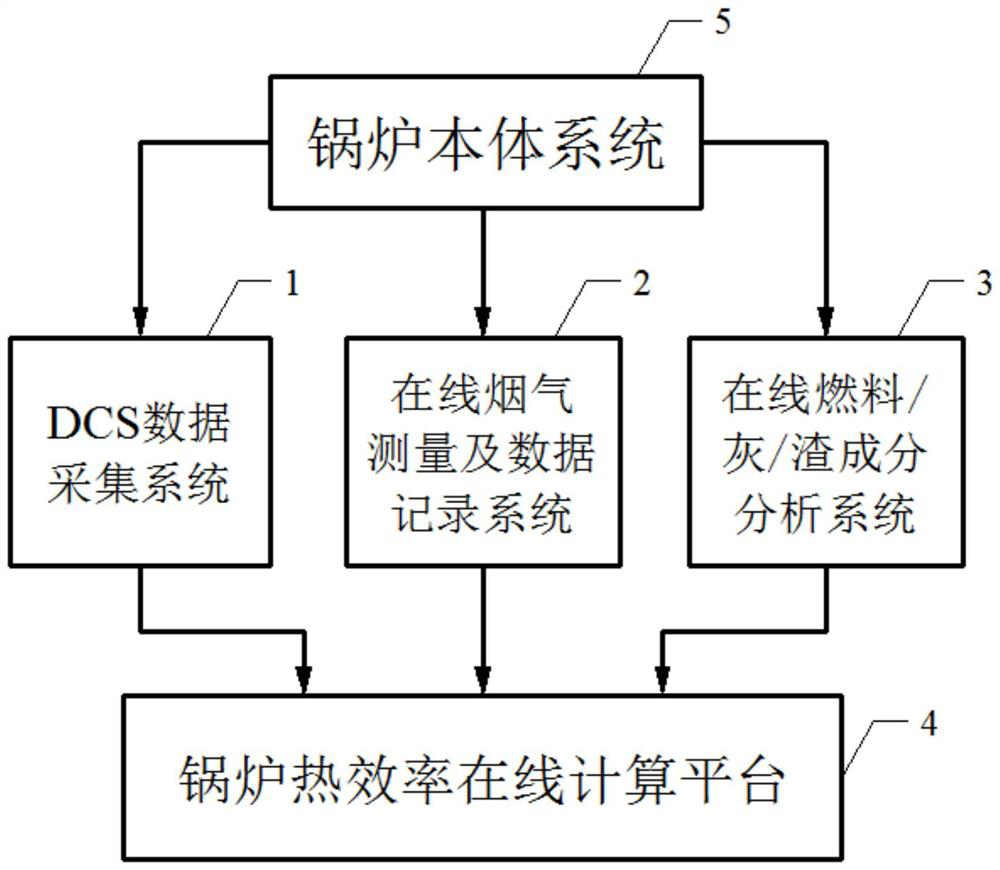

[0020] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the boiler thermal efficiency online calculation method of the domestic waste incineration boiler described in this embodiment, the calculation method is realized based on the boiler thermal efficiency online calculation system of the domestic waste incineration boiler, the domestic waste incineration boiler is an external Domestic waste incineration boiler with steam air preheater, the calculation system includes DCS data acquisition system 1, online flue gas measurement and data recording system 2, online fuel / ash / slag composition analysis system 3 and boiler thermal efficiency online calculation platform 4;

[0021] The calculation method includes the following steps:

[0022] S1. Use DCS data collection system 1, online flue gas measurement and data recording system 2 and online fuel / ash / slag composition analysis system 3 to collect data from the boiler body system 5, and ...

specific Embodiment approach 2

[0030] Specific embodiment 2: The difference between this embodiment and the boiler thermal efficiency online calculation method of domestic waste incineration boiler described in specific embodiment 1 is that in step S1, the DCS data acquisition system 1 and the online flue gas measurement and data recording system 2 are used and the online fuel / ash / slag component analysis system 3 carry out data collection to the boiler body system 5, and all the collected data are:

[0031] The data collected by DCS data acquisition system 1 includes D out , t zgs ,p zgs , t zzq ,p zzq ,p bh 、D bh , t bh.out ,p bh.out , t cq.in ,p cq.in 、D cq , t cq.out ,p cq.out ,q a1 , t a1 ,q a2 and t a2 ;

[0032] The data collected by the online flue gas measurement and data recording system 2 include t ds 、C O2 、C CO2 and C CO ;

[0033] The data collected by the online fuel / ash / slag composition analysis system 3 include Car 、H ar , O ar , S ar , N ar 、A ar , M ar , Q net....

specific Embodiment approach 3

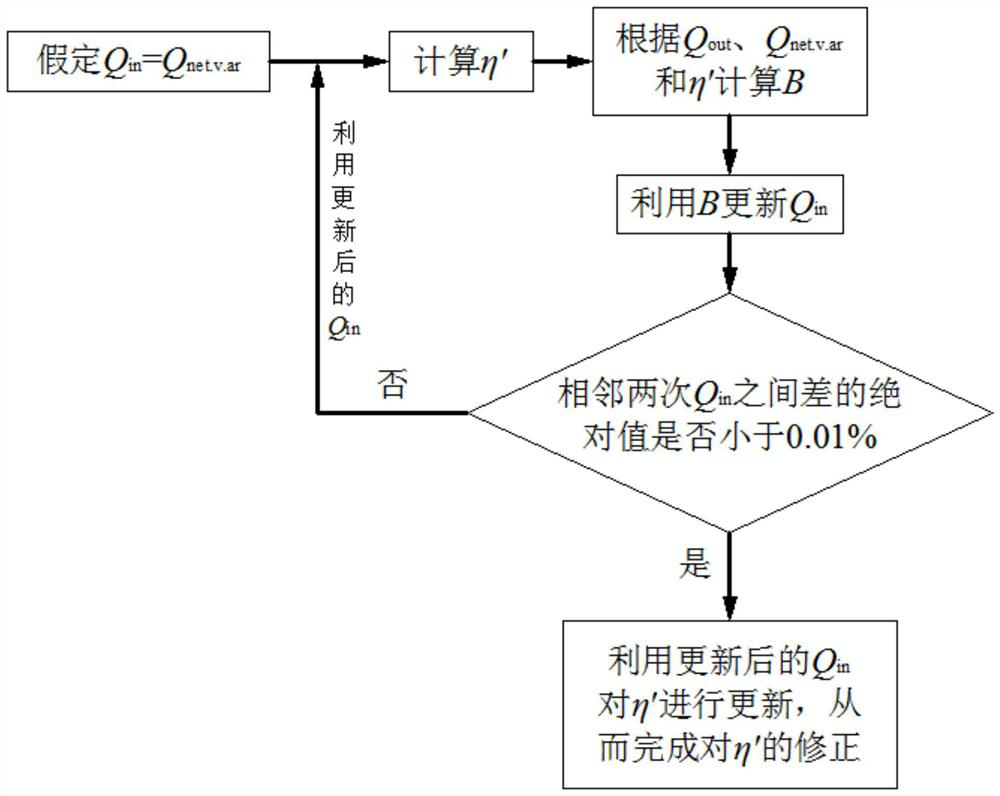

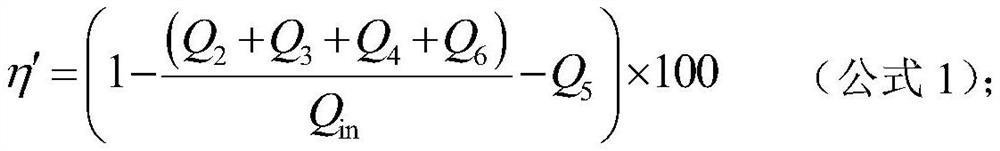

[0038] Specific embodiment three: the difference between this embodiment and the boiler thermal efficiency online calculation method of domestic waste incineration boiler described in specific embodiment two is that in step S1, the boiler thermal efficiency online calculation platform 4 uses the received data to obtain the exhaust heat loss Calorie Q 2 , Gas incomplete combustion heat loss heat Q 3 , Solid incomplete combustion heat loss heat Q 4 , Boiler heat dissipation loss Q 5 , Ash physical heat loss heat Q 6 and heat input Q in The implementation method includes the following steps:

[0039] S11. Obtain the input heat Q in The implementation method is: let Q in =Q net.v.ar ;

[0040] S12. Obtain heat loss Q of incomplete combustion heat of solid 4 The implementation method is:

[0041]

[0042] Among them, α s is the mass fraction of the ash content in the slag in the total ash content of the furnace fuel (dimensionless);

[0043] alpha as is the mass fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com