Method for preparing sintered insulating bricks from undisturbed wet sludge

A wet sludge and thermal insulation brick technology is applied in the field of solid waste resource utilization and building materials, which can solve the problems of occupying large land, secondary environmental pollution, and low utilization rate of resources, reducing consumption and improving utilization level. , the effect of relieving treatment pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

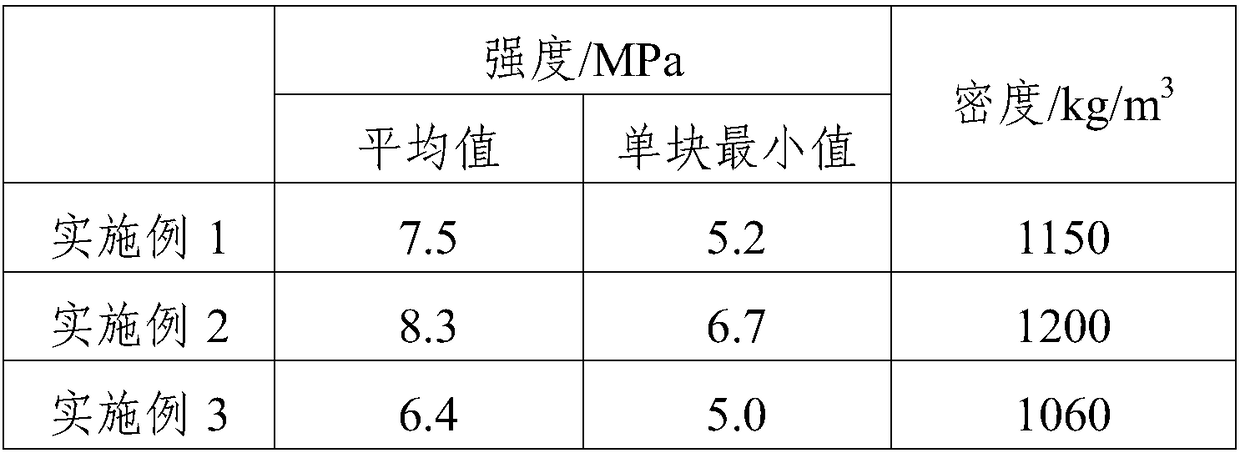

Embodiment 1

[0040] Prepare sintered insulation bricks according to the above method, and the specific process is as follows:

[0041] In step (1), the mass percentages of each component in the mixture are: the original wet sludge accounts for 25%, the foundation pit soil accounts for 55%, and the dry powder conditioning material accounts for 20%; the moisture content of the original wet sludge is 30%, and the dry powder The regulating material is dry powder material of construction waste, with an average particle size of 0.1-2.5mm.

[0042] In step (2), the aging time of the mixture is 3 days, the aging temperature is 40-45° C., and the humidity is 75%-80%.

[0043] In step (3), the semi-hard extrusion process is used for extrusion molding, and the pressure is 2.0 MPa.

[0044] In step (4), the temperature of the drying chamber is 165-175° C., and the drying time is 2.5 hours.

[0045] In step (5), the green body is sintered in a tunnel kiln at a temperature of 900-920° C. and a sinteri...

Embodiment 2

[0047] Prepare sintered insulation bricks according to the above method, and the specific process is as follows:

[0048] In step (1), the mass percentages of each component in the mixture are: the original wet sludge accounts for 30%, the foundation pit soil accounts for 55%, and the dry powder conditioning material accounts for 15%; the moisture content of the original wet sludge is 40%, and the dry powder The regulating material is dry powder material of construction waste, with an average particle size of 0.1-2.5mm.

[0049] In step (2), the aging time of the mixture is 3 days, the aging temperature is 42-45° C., and the humidity is 75%-80%.

[0050] In step (3), the semi-hard extrusion process is used for extrusion molding, and the pressure is 2.2 MPa.

[0051] In step (4), the temperature of the drying chamber is 165-175° C., and the drying time is 3 hours;

[0052] In step (5), the green body is sintered in a tunnel kiln at a temperature of 900-920° C. and a sintering...

Embodiment 3

[0054] Prepare sintered insulation bricks according to the above method, and the specific process is as follows:

[0055] In step (1), the mass percentages of each component in the mixture are: the original wet sludge accounts for 40%, the foundation pit soil accounts for 45%, and the dry powder conditioning material accounts for 15%; the moisture content of the original wet sludge is 50%, and the dry powder The regulating material is dry powder material of construction waste, with an average particle size of 0.1-2.5mm.

[0056] In step (2), the aging time of the mixture is 4 days, the aging temperature is 40-45° C., and the humidity is 70%-80%.

[0057] In step (3), the semi-hard extrusion process is used for extrusion molding, and the pressure is 2.5 MPa.

[0058] In step (4), the temperature of the drying chamber is 165-175° C., and the drying time is 3 hours.

[0059] In step (5), the green body is sintered in a tunnel kiln at a temperature of 920-950° C. and a sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com