Preparation method of biological foaming agent based on microbial fermentation

A foaming agent and bio-based technology, applied in the field of foam, can solve the problems of corrosiveness of personnel and equipment, environmental pollution of the surrounding environment, insufficient foaming efficiency, etc., and achieve good environmental protection, low gas diffusion rate, and uniform foam and fine effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

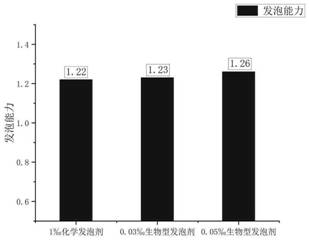

Image

Examples

Embodiment example 1

[0022] Implementation Case 1: Foaming Basic Material for Mine Dust Suppression Foam Technology

[0023]First, prepare a 10ml test tube containing 5ml of liquid activation medium and two solid activation medium, pipette 0.5ml of liquid activation medium into the freeze-drying tube, mix thoroughly, and pour the bacterial solution back into the solid-state activation culture base, mix evenly, absorb the bacterial solution, and evenly spread it on the solid-state activated medium plate, each plate is coated with 0.2ml of the bacterial solution, and the whole process should be completed on a sterile operating table. Place the liquid activation medium and the solid activation medium in a constant temperature incubator at 37°C for 24 hours; if the colonies in the liquid activation medium are pale pink, round, with irregular edges, wrinkled, opaque, and turn from wet to dry The flat colony shape, and the solid-state activation medium microscopic colony is obvious, it shows that the st...

Embodiment example 2

[0028] Implementation case 2: Foaming base material for mine fire foam technology

[0029] First, prepare a 10ml test tube containing 5ml of liquid activation medium and two solid activation medium, pipette 0.5ml of liquid activation medium into the freeze-drying tube, mix thoroughly, and pour the bacterial solution back into the solid-state activation culture base, mix evenly, absorb the bacterial solution, and evenly spread it on the solid-state activated medium plate, and apply 0.3ml of the bacterial solution on each plate. The whole process should be completed on a sterile operating table. Place the liquid activation medium and the solid activation medium in a constant temperature incubator at 37°C for 36 hours; if the colony in the liquid activation medium is pale pink, round, with irregular edges, wrinkled, opaque, and turns from wet to dry The flat colony shape, and the solid-state activation medium microscopic colony is obvious, it shows that the strain can be used as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com