Self-thickening multicolor paint and application thereof

A self-thickening technology for multi-color coatings, applied in the field of coatings, can solve the problems of whitening of coatings when exposed to water, affecting the water resistance of multi-color coatings, and foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

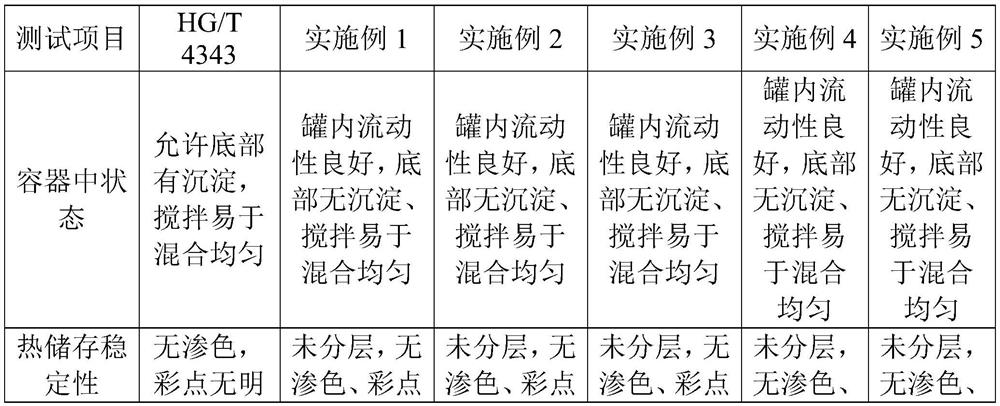

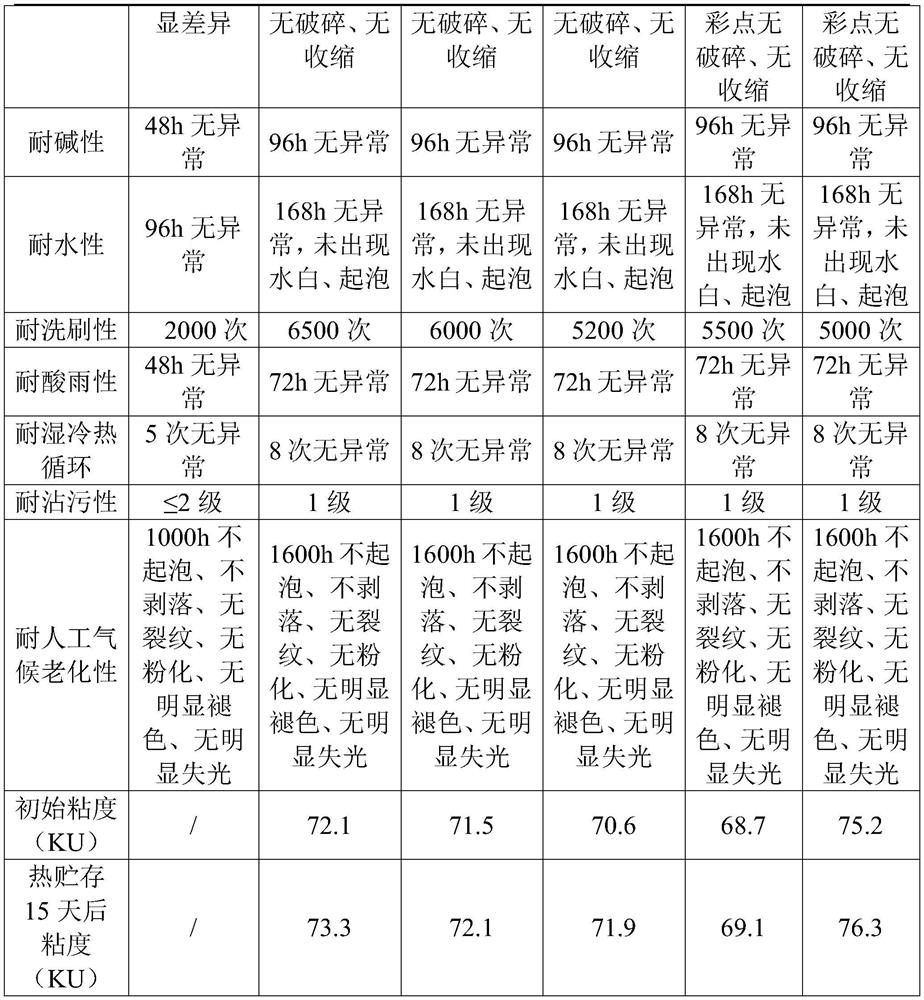

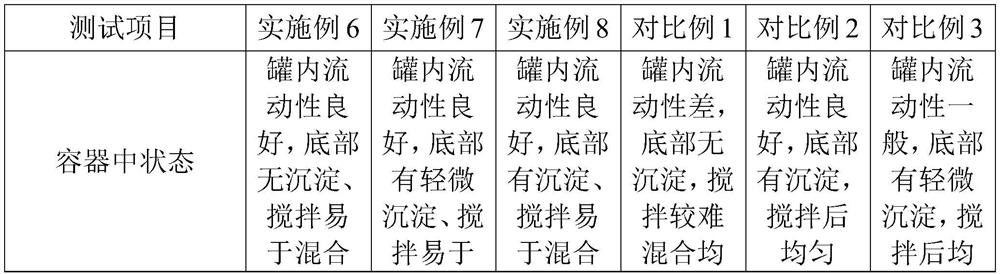

Examples

preparation example Construction

[0059] The preparation method of the self-thickening colorful paint includes the following steps S100-S300.

[0060] Step S100: Mix and granulate the base paint and the granulation solution to prepare color dots.

[0061] Step S200: thickening the colored dots by mixing with the self-thickening continuous phase.

[0062] Step S300: mixing the inactive continuous phase with the colored dots thickened by mixing and the self-thickening continuous phase.

[0063] The above-mentioned self-thickening colorful paint includes base paint, granulation liquid, self-thickening continuous phase and inactive continuous phase, and the color dots are mixed with self-thickening continuous phase and inactive continuous phase step by step, and the protective glue can be formed with the continuous phase Directional and controllable self-thickening reaction, controllable viscosity of coating, good storage stability. The matting powder and talcum powder in the self-thickening continuous phase and...

Embodiment 1

[0105] The raw material of the self-thickening colorful paint of the present embodiment is made up of following components:

[0106] Granulation liquid: 93 parts of deionized water, 7 parts of protective gel and 0.1 part of fungicide.

[0107] Base paint: 46.6 parts of deionized water, 1 part of cellulose, 0.3 parts of the first dispersant, 0.1 part of AMP-95, 0.1 part of defoamer, 0.1 part of fungicide, 1 part of titanium dioxide, 7 parts of calcined kaolin, hollow glass 1 part of microbeads, 35 parts of the first emulsion, 1.5 parts of film-forming aid, 1 part of antifreeze, 0.28 parts of protective glue and 1 part of water-based color paste.

[0108] Self-thickening continuous phase: 26.05 parts of deionized water, 3 parts of film-forming aids, 2 parts of antifreeze, 3.5 parts of second dispersant, 0.2 parts of substrate wetting agent, 0.7 parts of silane coupling agent, 3.5 parts of matting powder , 0.8 parts of talcum powder, 60 parts of the second emulsion, 0.15 parts o...

Embodiment 2

[0122] The raw material of the self-thickening colorful paint of the present embodiment is made up of following components:

[0123] Granulation solution: 94 parts of deionized water, 6 parts of protective gel and 0.1 part of fungicide.

[0124] Base paint: 40.22 parts of deionized water, 1.1 parts of cellulose, 0.35 parts of the first dispersant, 0.1 parts of AMP-95, 0.2 parts of defoamer, 0.08 parts of fungicide, 1 part of titanium dioxide, 7.2 parts of calcined kaolin, hollow glass 0.8 parts of microbeads, 40 parts of the first emulsion, 2 parts of film-forming aids, 1 part of antifreeze, 0.29 parts of protective glue and 1 part of water-based color paste.

[0125] Self-thickening continuous phase: 16.5 parts of deionized water, 3.5 parts of film-forming aid, 2 parts of antifreeze, 3 parts of second dispersant, 0.15 part of substrate wetting agent, 0.5 part of silane coupling agent, 3 parts of matting powder , 1 part of talcum powder, 60 parts of the second emulsion, 0.2 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com