Staged photocureable coating, thermal transfer film, decorative device and preparation method

A technology of photocurable coating and thermal transfer film, applied in the directions of copying/marking method, coating, printing, etc., can solve the problem of not meeting the market demand, the thermal transfer film has no stretchability, and can not meet the surface of special-shaped devices decoration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

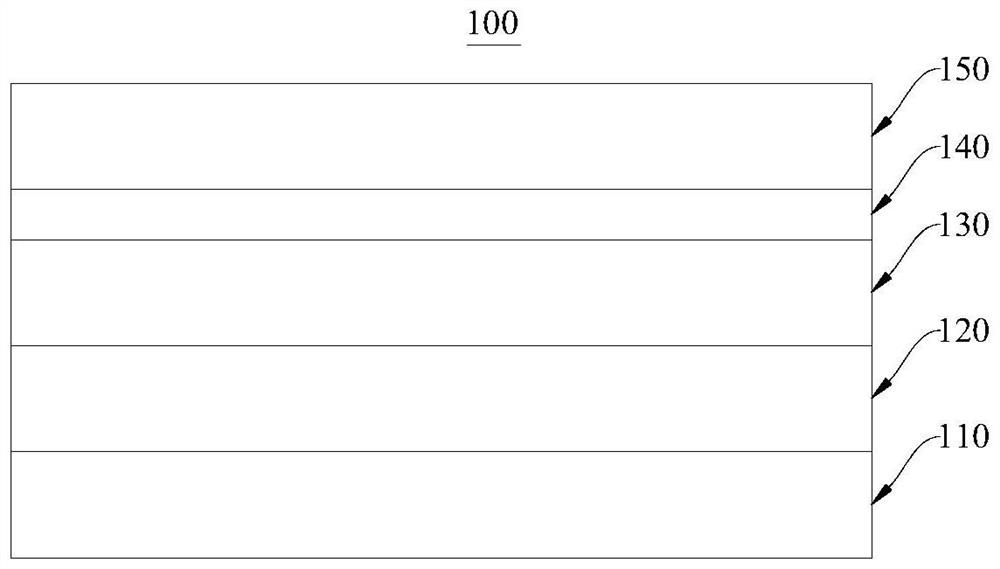

[0060] The embodiment of the present application also provides a method for preparing the above-mentioned thermal transfer film 100, which includes the following steps:

[0061] (1) Coating the release layer 120 paint on the base film layer 110 and curing naturally to form the release layer 120 .

[0062] (2) On the release layer 120, apply a step-by-step light-curing coating, and use a UV mercury lamp with a power of 40-120W / cm to irradiate and cure for 10-60s to form a semi-cured functional layer 130. The curing rate of the semi-cured functional layer 130 is 40%-80%.

[0063] (3) Print ink on the semi-cured functional layer 130 to form the graphic layer 140 .

[0064] (4) Coating the adhesive on the graphic layer 140 and curing naturally to form the adhesive layer 150 .

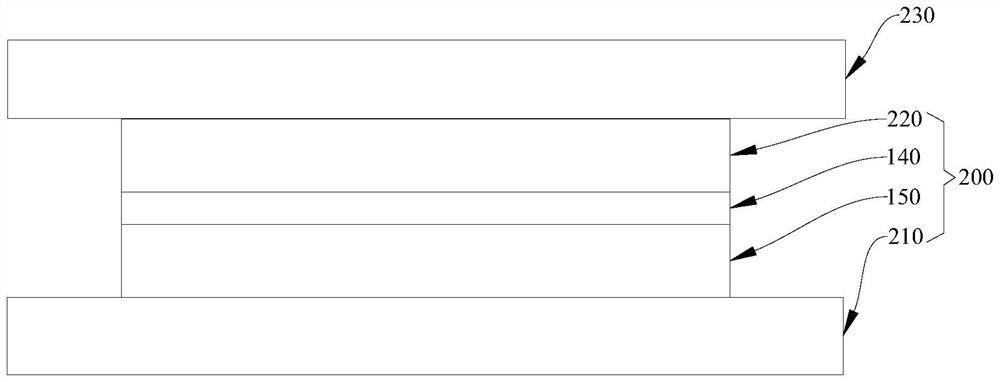

[0065] Please see figure 1 and figure 2 , the embodiment of the present application also provides a decorative device 200, which includes a device 210, and an adhesive layer 150, a graphic layer 140 an...

Embodiment 1

[0071] This embodiment provides a thermal transfer film, which is composed of a base film layer, a release layer, a functional layer, a graphic layer and an adhesive layer stacked sequentially from top to bottom, and its preparation process is as follows:

[0072] (1) Coating solvent-based release wax on a 15 μm PET base film layer to form a 2 μm thick release layer.

[0073] (2) Preparation of staged light-curing coatings: by weight, 25 parts of Xiamen Weiliang Chemical UV3540, 25 parts of Dongguan Xinyue Electronic Materials Co., Ltd. SY-5213, 50 parts of Changxing Chemical 4220, 5 parts of methyl acrylate, 8 parts of tripropylene glycol diacrylate, 1 part of 2-hydroxy-2-methyl-1-phenylacetone and 3 parts of Shin-Etsu Chemical Fluere UV-300, all the raw materials were stirred at room temperature to obtain the final product.

[0074] Apply staged light-cured coatings on the release layer to form a coating, and UV-cure for 30s under the UV mercury lamp with a power of 40-120W / ...

Embodiment 2

[0079] This embodiment provides a thermal transfer film, which is composed of a base film layer, a release layer, a functional layer, a graphic layer and an adhesive layer stacked sequentially from top to bottom, and its preparation process is as follows:

[0080] (1) Coating solvent-based release wax on a 23 μm PET base film layer to form a 5 μm thick release layer.

[0081] (2) Preparation of staged light-curing coatings: by weight, 30 parts of Xiamen Weiliang Chemical UV3542, 30 parts of Changxing Chemical 6071, 20 parts of Changxing Chemical 3508, 20 parts of Huanan Fine Chemical G21, 8 parts of methacrylic acid- 2,2,2-Trifluoroethyl ester, 4 parts of pentaerythritol triacrylate, 2 parts of 1-hydroxycyclohexyl benzophenone and 4 parts of Daikin Fluorochemical OPTOOL DAC-HP, all the raw materials were stirred at room temperature, namely have to.

[0082] Coating staged photocuring coatings on the release layer to form a coating, UV curing for 40s under UV mercury lamp ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com