Antistatic fading-free rubber and preparation method thereof

An antistatic and antistatic agent technology, which is applied in the field of antistatic and non-fading rubber and its preparation, can solve the problems of serious dyeing, restrictions on the conductivity of carbon black, and the use of antistatic rubber, so as to achieve stable antistatic performance and improve use performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] In order to solve the problems in the prior art, the current conventional rubber products usually use carbon black materials in the case of permanent antistatic. This material is seriously dyed and will leave black marks on the contacted substances during the contact and friction process. Problem, the present invention provides an antistatic non-fading rubber and its preparation method.

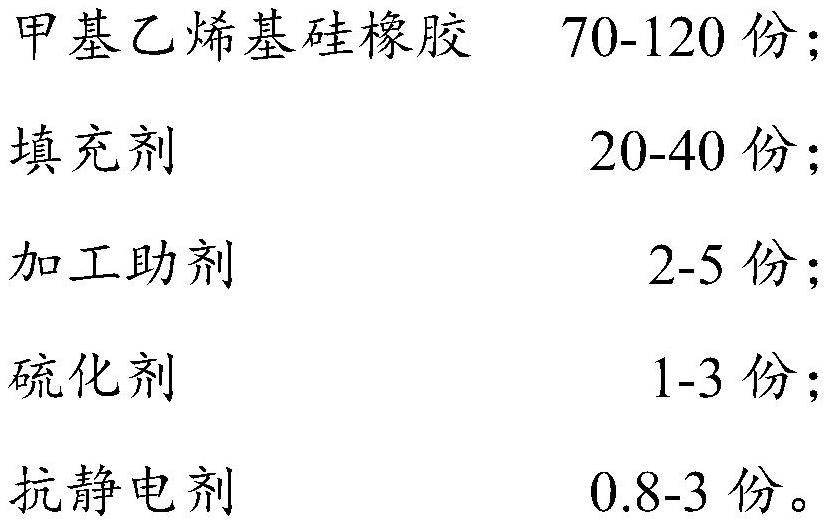

[0022] The invention provides an antistatic and non-fading rubber. The raw material of the rubber includes the following components in parts by weight:

[0023]

[0024] The methyl vinyl silicone rubber selected in the present invention has excellent anti-aging, low-temperature resistance and high-temperature resistance, can be used normally in the range of -60°C to 250°C, and does not produce sulfur-containing substances, and is not harmful to copper-like metal materials. Will produce corrosion phenomenon, can be widely used in the electronics industry.

[0025] In order to adjust...

Embodiment 1

[0039] This embodiment provides an antistatic and non-fading rubber. The raw material of the rubber includes the following components in parts by weight: 100 parts of methyl vinyl silicone rubber, 40 parts of silicon dioxide, 3 parts of methyl silicone oil, 2 parts of 2, 5-Dimethyl-2,5-bis(tert-butylperoxy)hexane, 2 parts of graphene (average particle size is 2nm, specific surface area is 1000m 2 / g).

[0040] This embodiment also provides a preparation method of antistatic and non-fading rubber, comprising the following steps,

[0041] Weigh 100 parts of methyl ethyl silicone rubber, 40 parts of silicon dioxide, 3 parts of methyl silicone oil, 2 parts of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane , 2 parts of graphene (average particle size is 2nm, specific surface area is 1000m 2 / g) Mix in an open mill so that the components are evenly dispersed, and then vulcanized to obtain antistatic and non-fading rubber.

Embodiment 2

[0043] This embodiment provides an antistatic and non-fading rubber, which is basically the same as in Embodiment 1, except that the raw material of the rubber includes the following components in parts by weight: 100 parts of methyl vinyl silicone rubber, 30 parts of di Silicon oxide, 5 parts of methyl silicone oil, 1 part of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 2 parts of graphene (average particle size is 2nm, specific surface area is 1000m 2 / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com