Slaughter and meat processing industrial wastewater treatment device and operation method thereof

A technology for industrial wastewater and meat processing, which is applied in animal processing wastewater treatment, biological treatment adjustment method, aerobic and anaerobic process treatment, etc. It can solve the problems of low removal efficiency, high energy consumption, unstable operation, etc. To achieve the effect of enhanced removal removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

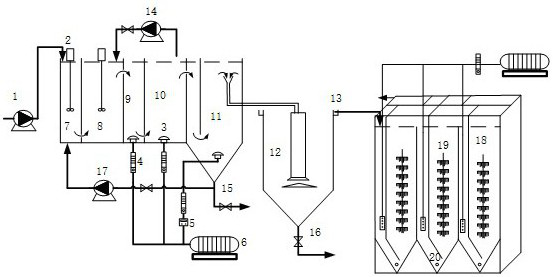

[0019] The specific content of the present invention will be described in detail with reference to the accompanying drawings. like figure 1 Shown, a slaughtering and meat processing industrial wastewater treatment plant comprising improved A 2 / O reactor and SNAD autotrophic denitrification reactor, in which modified A 2 The / O reactor is composed of a reaction tank and a sedimentation tank 12 connected by pipelines in sequence. The reaction tank is divided into anaerobic zone 7, anoxic zone 8, aerobic zone I 9, and aerobic zone II by partitions along the water inlet direction. 10 and the intermittent aeration zone 11, the upper and lower parts of the adjacent partitions are respectively provided with through holes, for realizing that the waste water reaches the baffle effect in each reaction zone of the reaction tank, and the aerobic zone II 10 is returned by the mixed liquid peristaltic pump 14 and 10. The pipeline is communicated with the anoxic zone 8 to realize the retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com