Drilling tool

A technology for drilling tools and tools, which is applied in the field of drilling tools and can solve problems such as excessive rotation of the housing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

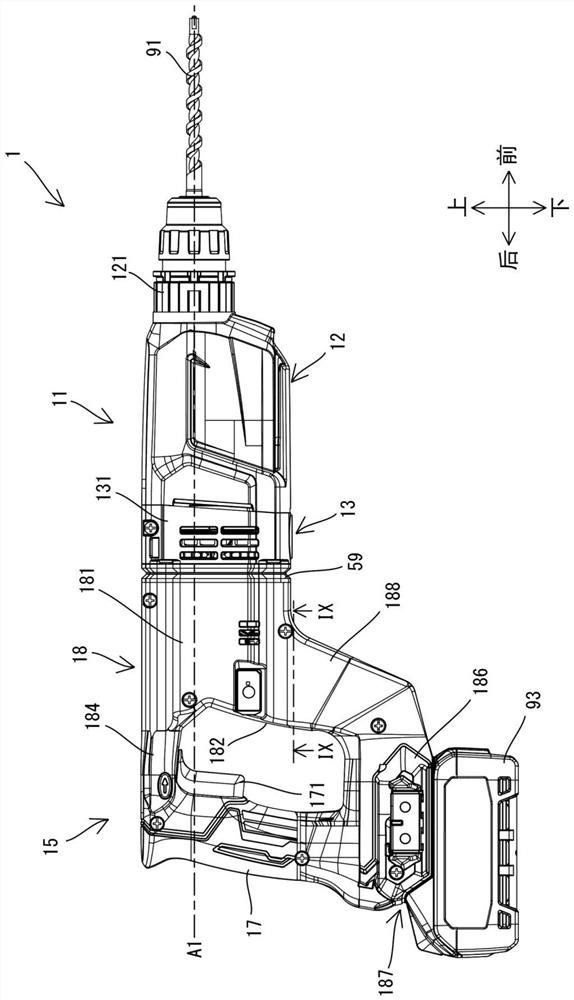

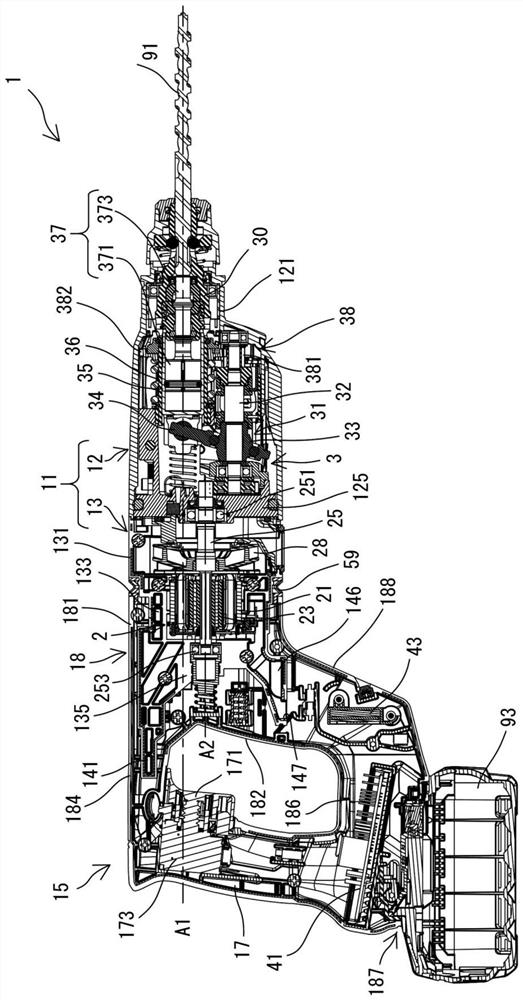

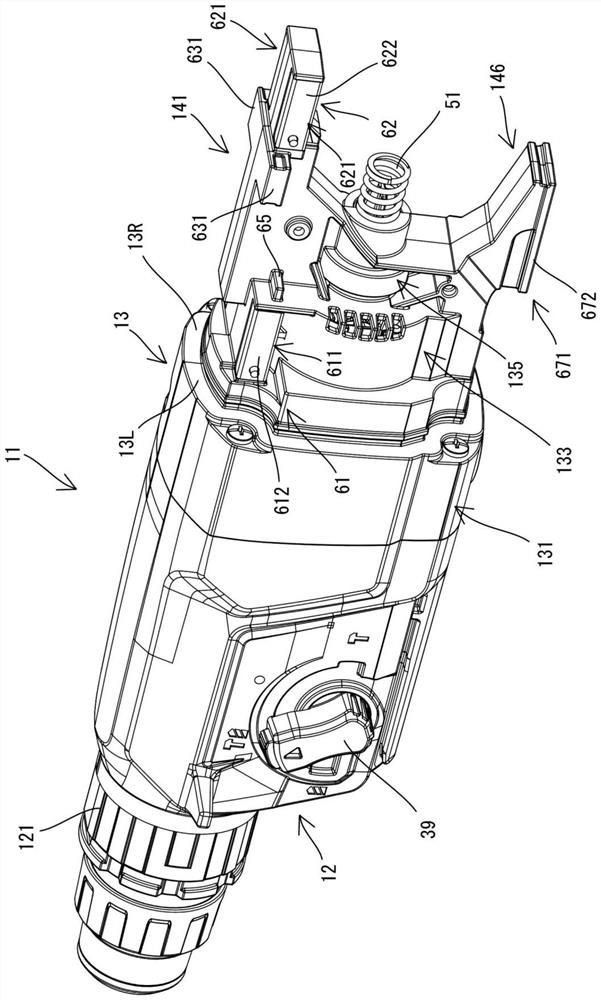

[0033] Embodiments are described below with reference to the drawings. In addition, in the following embodiments, a hand hammer drill 1 which is an example of an impact tool and an example of a drilling tool is illustrated. The hammer drill 1 is configured to be capable of performing an operation of linearly driving the tip tool 91 along a predetermined drive axis A1 (hereinafter referred to as an impact operation) and an operation of driving the tip tool 91 to rotate around the drive axis A1 (hereinafter referred to as a drilling operation). ).

[0034] First, the schematic structure of the hammer drill 1 will be described. Such as figure 1 with figure 2As shown, the external contour of the hammer drill 1 is mainly formed by the main body housing 11 and the handle housing 15 . In this embodiment, both the main body case 11 and the handle case 15 are made of synthetic resin.

[0035] The main body case 11 is a long hollow body extending along the drive axis A1. A tool h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com