Equipment capable of sorting construction waste for multiple times based on environmental protection industry

A construction waste and industrial technology, applied in the field of equipment that can sort construction waste multiple times, can solve the problems of low screening efficiency of construction waste, pollution of surrounding surface water and groundwater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

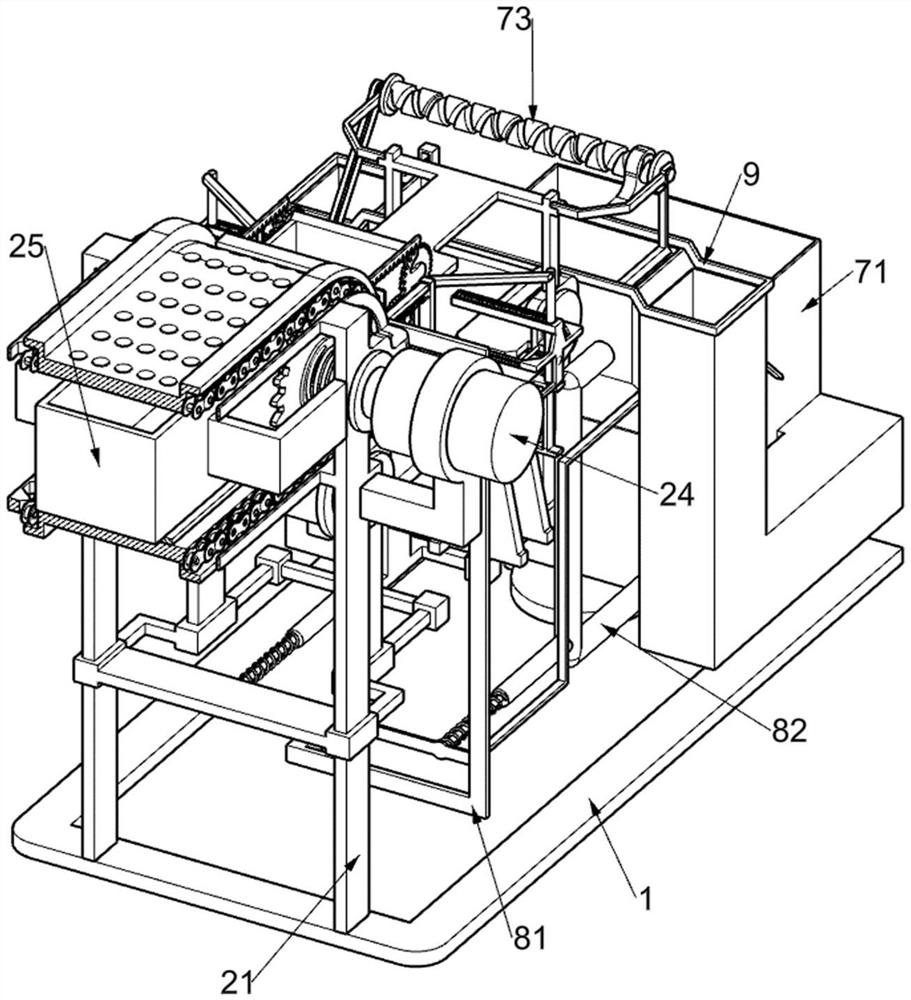

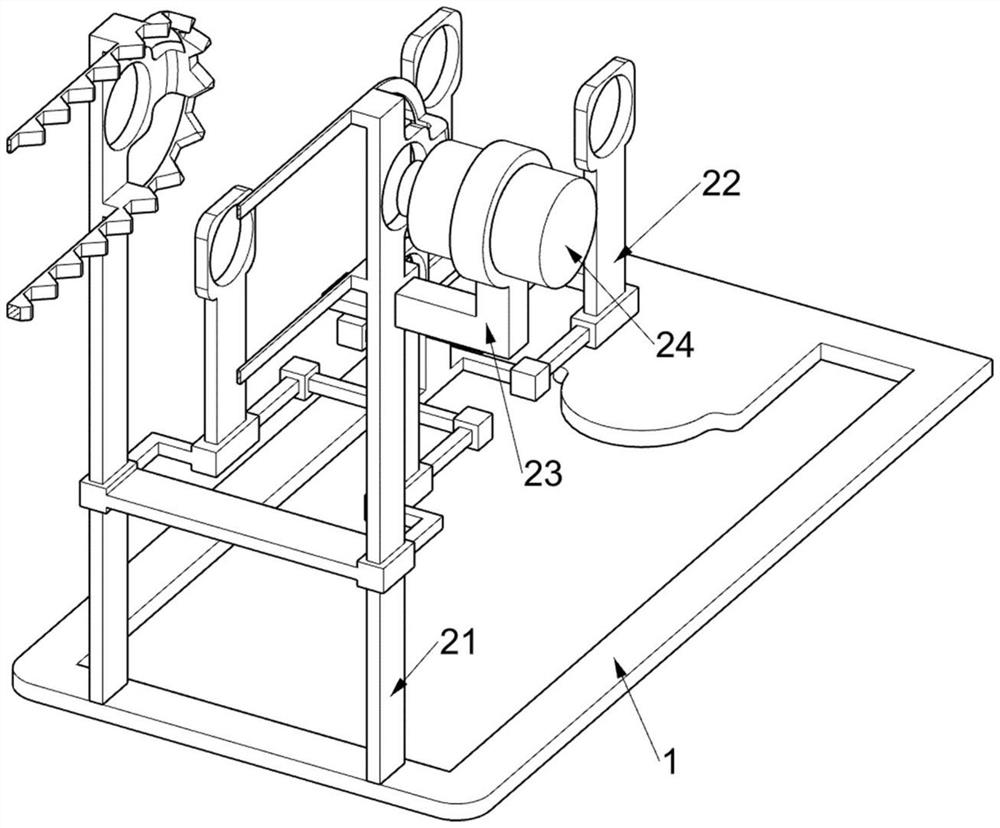

[0046] A device based on the environmental protection industry that can sort construction waste multiple times, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, it includes a bottom plate 1, a special-shaped support frame 21, a four-corner opening frame 22, a motor support seat 23, a servo motor 24, a waste soil storage frame 25, a waste soil sieving assembly 3, a crushing assembly 4 and an intermittent transportation assembly 5. A special-shaped support frame 21 is fixedly installed on the top surface of the bottom plate 1, and a four-corner opening frame 22 is fixedly installed on the special-shaped support frame 21. A motor support base 23 is fixedly installed on the special-shaped support frame 21, and a servo motor 24 is fixedly installed on the motor support base 23. , the waste soil receiving frame 25 is fixedly installed on the special-shaped support frame 21, and the special-shaped suppo...

Embodiment 2

[0053] On the basis of Example 1, such as Figure 8 , Figure 9 with Figure 10 As shown, it also includes a magnetic separation assembly 6. The magnetic separation assembly 6 is symmetrically arranged on the four-corner opening frame 22. The magnetic separation assembly 6 is used to screen the metal materials in the construction waste. The magnetic separation assembly 6 includes special-shaped materials Frame 61, special-shaped slotting frame 62, special-shaped gear 63, sliding rack frame 64, second return spring 65, driving rod sliding frame 66, third returning spring 67, driving rod slotting frame 68, fourth returning spring 69, Control switch 610, electromagnet piece 611 and the 5th back-moving spring 612, the special-shaped material frame 61 that is used to place metal material is symmetrically arranged on the four corners opening frame 22, is fixedly installed with special-shaped slotting frame 62 on the special-shaped material frame 61, and special-shaped bottom Symme...

Embodiment 3

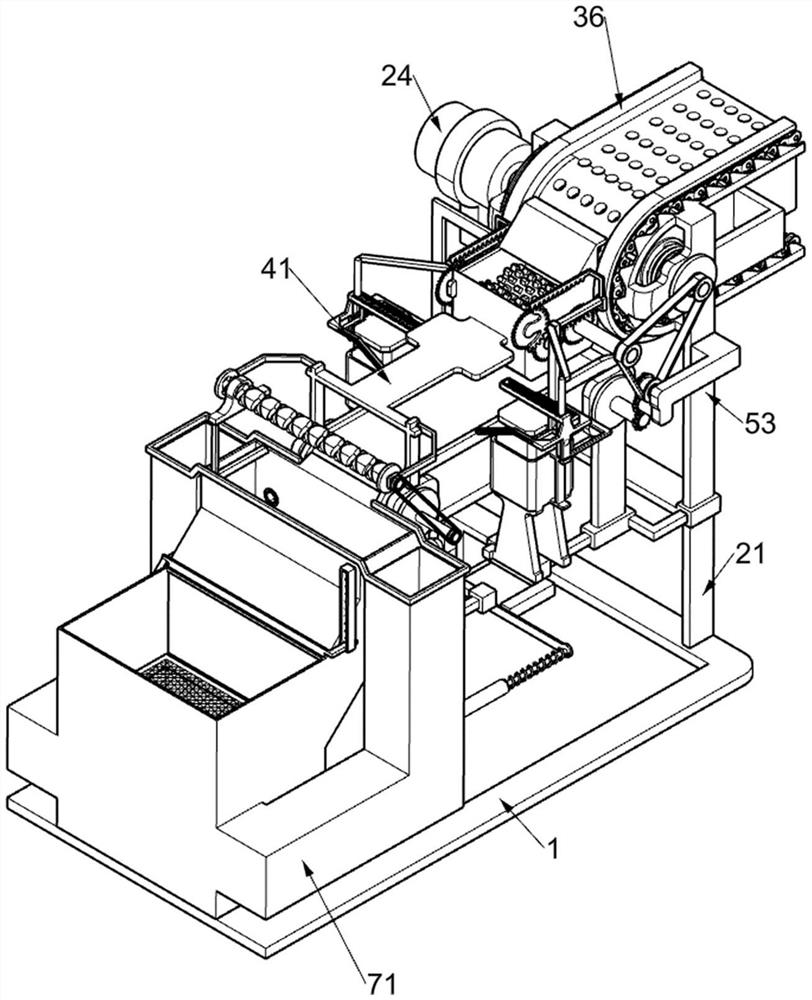

[0056] On the basis of Example 2, such as Figure 11 , Figure 12 , Figure 13 , Figure 14 with Figure 16 As shown, a water separation assembly 7 is also included. The top surface of the bottom plate 1 is provided with a water separation assembly 7. The water separation assembly 7 is used to screen out plastic waste. The water separation assembly 7 includes a special-shaped drainage box 71 and an N-shaped support frame. 72. Reciprocating lead screw 73, push plate 74, pulley two 75, belt two 76, small filter screen 77, large filter screen 78, sliding plate 79, rectangular slotted frame 710 and sixth return spring 711, bottom plate 1 top surface A special-shaped drainage box 71 for water storage is fixedly installed, and the special-shaped drainage box 71 is in contact with the conveyor belt 52. An N-shaped support frame 72 is symmetrically arranged on the special-shaped blanking frame 41, and two N-shaped support frames 72 are jointly rotated. Leading screw 73, on the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com