Shaft screening device

A technology for screening equipment and shaft diameters, applied in solid separation, classification, chemical instruments and methods, etc., can solve problems such as wrong screening and complicated rework procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

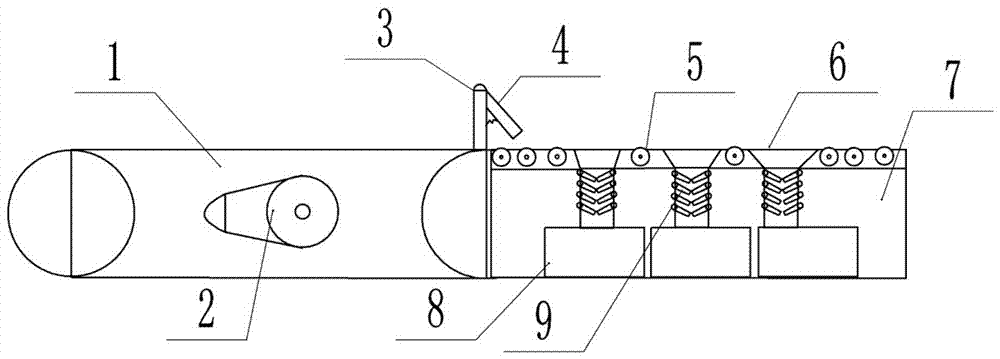

[0014] The reference signs in the drawings of the description include: conveyor belt 1, cam 2, discharge frame 3, baffle plate 4, drive roller 5, screening tank 6, base 7, material box 8, buffer plate 9.

[0015] The embodiment is basically as figure 1 Shown:

[0016] The shaft screening equipment of this embodiment includes a conveyor belt 1 for transporting shaft workpieces. A cam 2 is rotatably connected to the inside of the conveyor belt 1. The highest point of the movement of the cam 2 is higher than the upper surface of the conveyor belt 1. The output pipe of the conveyor belt 1 is fixedly connected. There is a discharge frame 3, a baffle 4 is hinged on the discharge frame 3, a spring connected to the side wall of the discharge frame 3 is provided on the baffle 4, and a screening mechanism is provided on one side of the conveyor belt 1, and the screening mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com