Automatic impurity determinator and impurity determination method

An automatic technology for impurity determination, applied in instruments, analytical materials, etc., can solve problems such as low efficiency, flying carbon black dust, environmental and personal health hazards, etc., to improve stability, facilitate replacement and cleaning, and improve sample detection efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

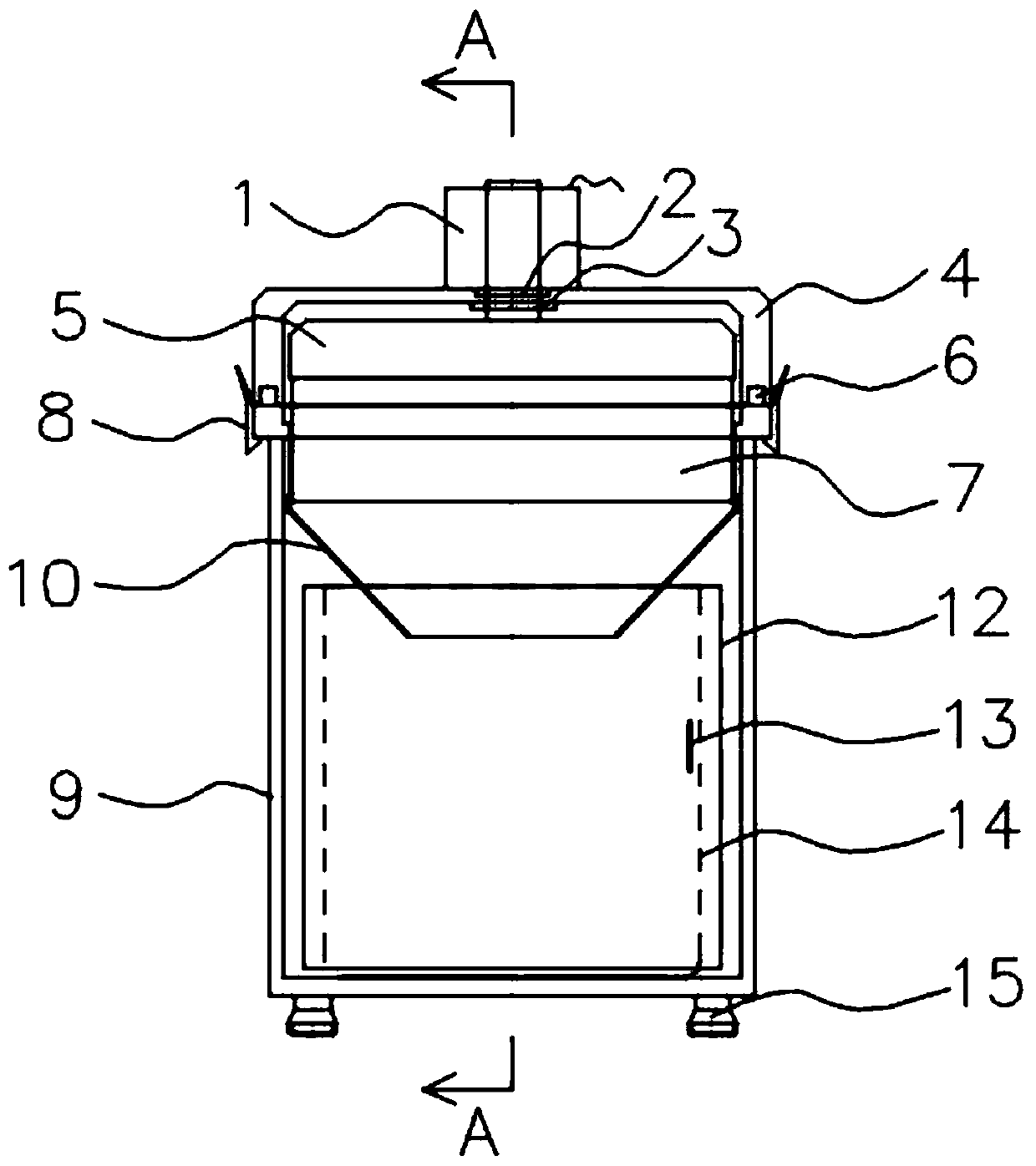

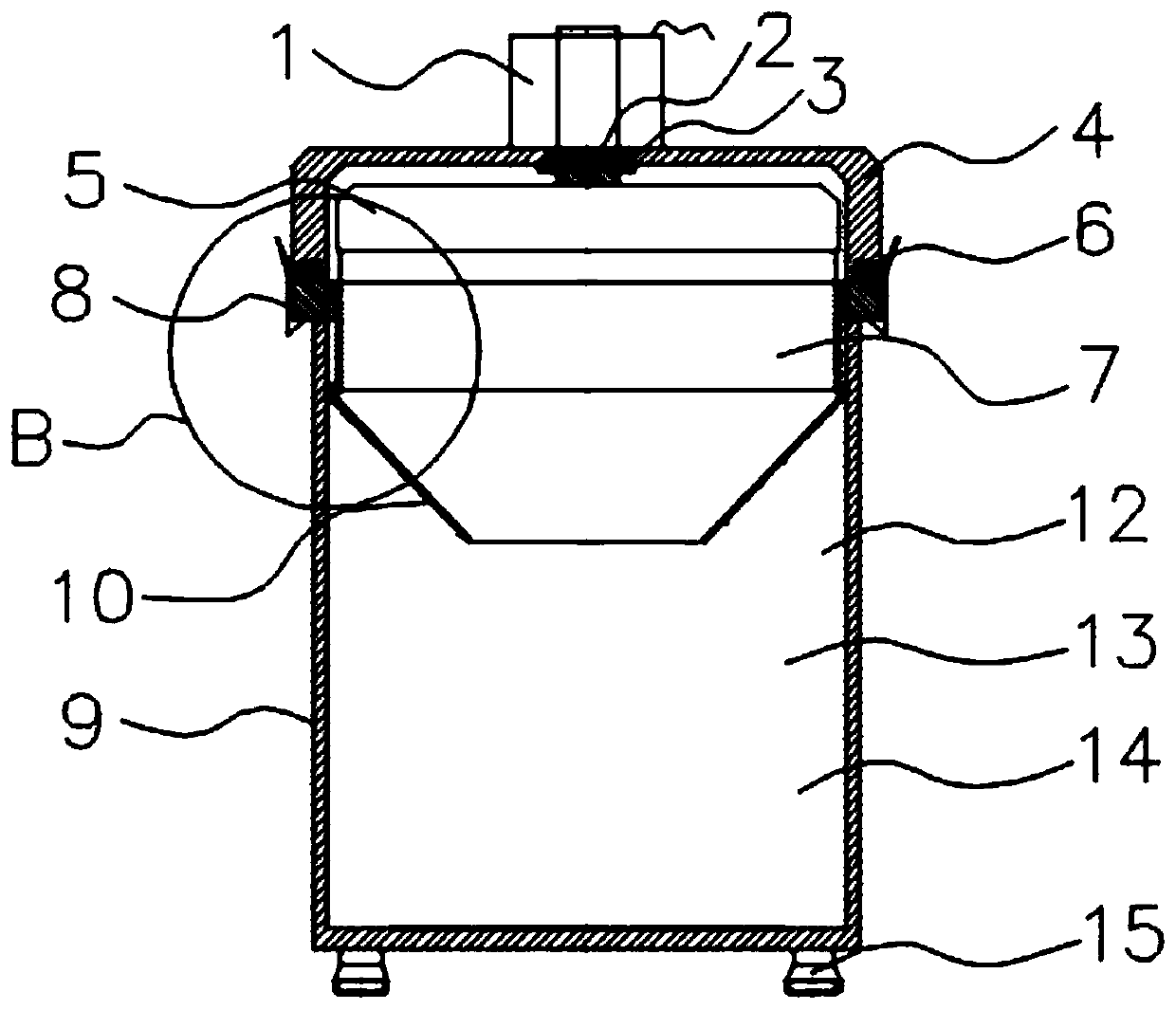

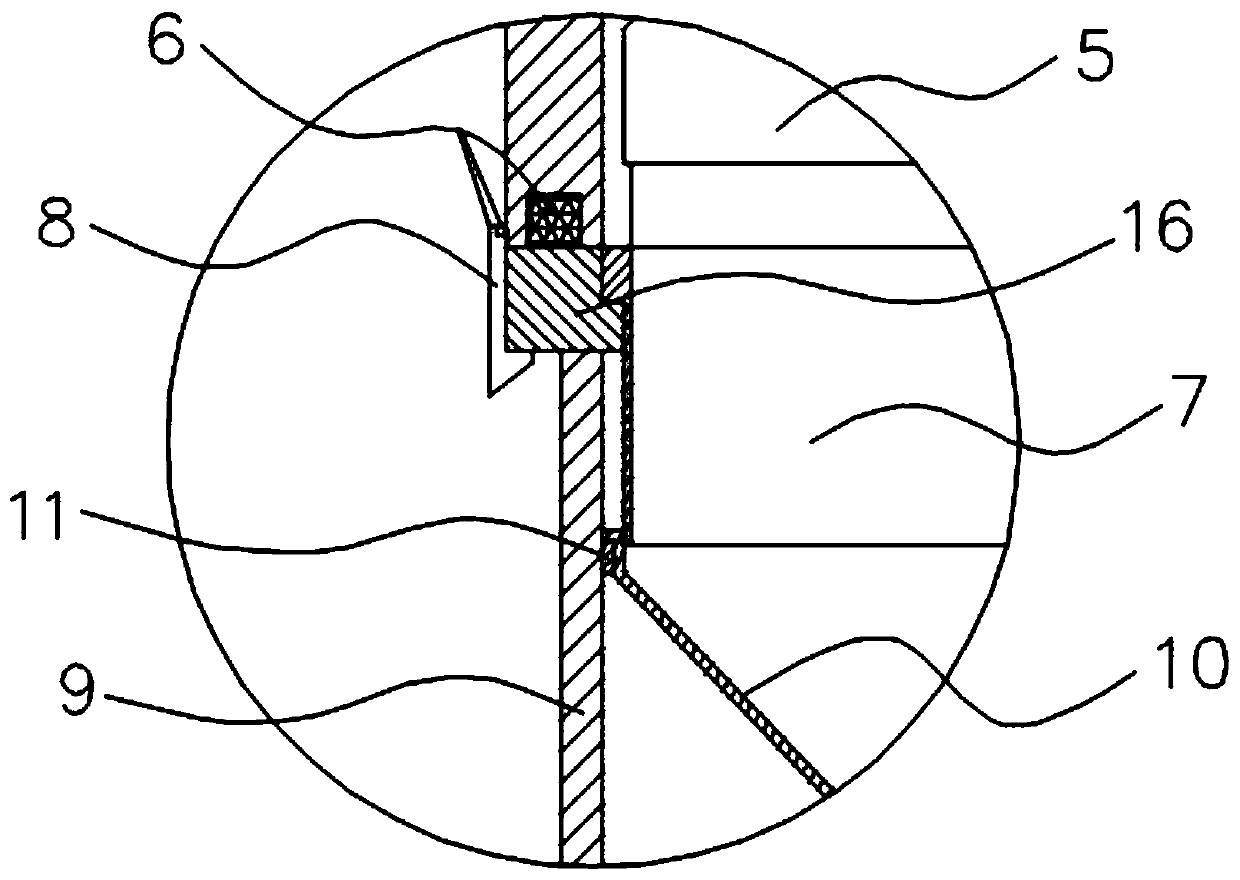

[0032] like figure 1 and figure 2 As shown, an automatic impurity analyzer includes a support cylinder 9 and a cover plate 4 arranged at the top opening of the support cylinder 9, the top of the cover plate 4 is provided with a speed regulating motor 1, and the top of the cover plate 4 is provided with Position the motor installation positioning slot 2 of the speed-regulating motor 1, the inside of the cover plate 4 is provided with a hair brush 5, and the hair brush 5 includes a connecting plate connected with the output shaft of the speed-regulating motor 1, and the bottom of the connecting plate passes through The spring is connected with a mounting plate, and the bottom of the mounting plate is provided with bristles, so that the height of the bristles of the hair brush 5 is adjustable, ensuring that the height of the hair brush 5 is greater than the distance between the screen surface of the mesh screen 7 and the cover plate 4, so that the hair brush 5 When rotating, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com