MFI molecular sieve and preparation method and application thereof

A technology of molecular sieve and tetraethyl silicate, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of insufficient catalytic activity of active center skeleton titanium and insufficient catalytic activity of TS-1 molecular sieve, etc. Achieve the effect of shortening the reaction time and improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

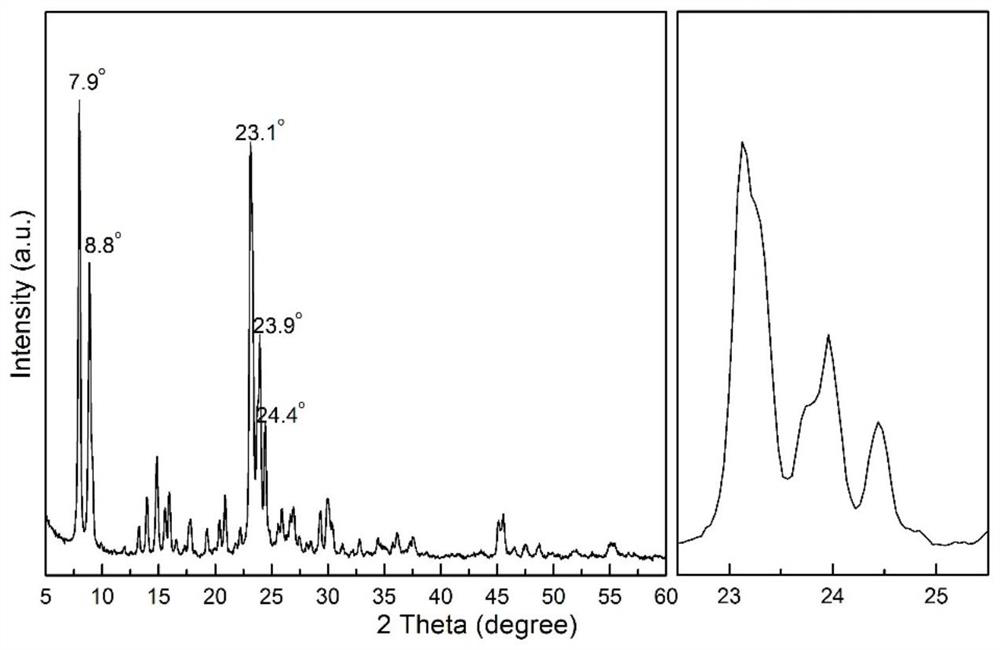

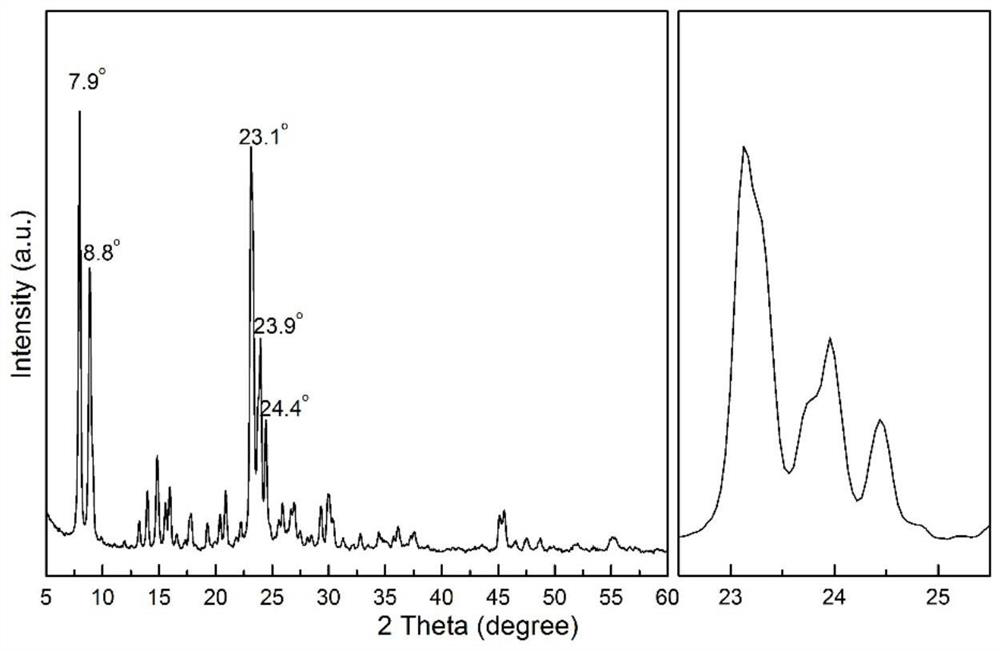

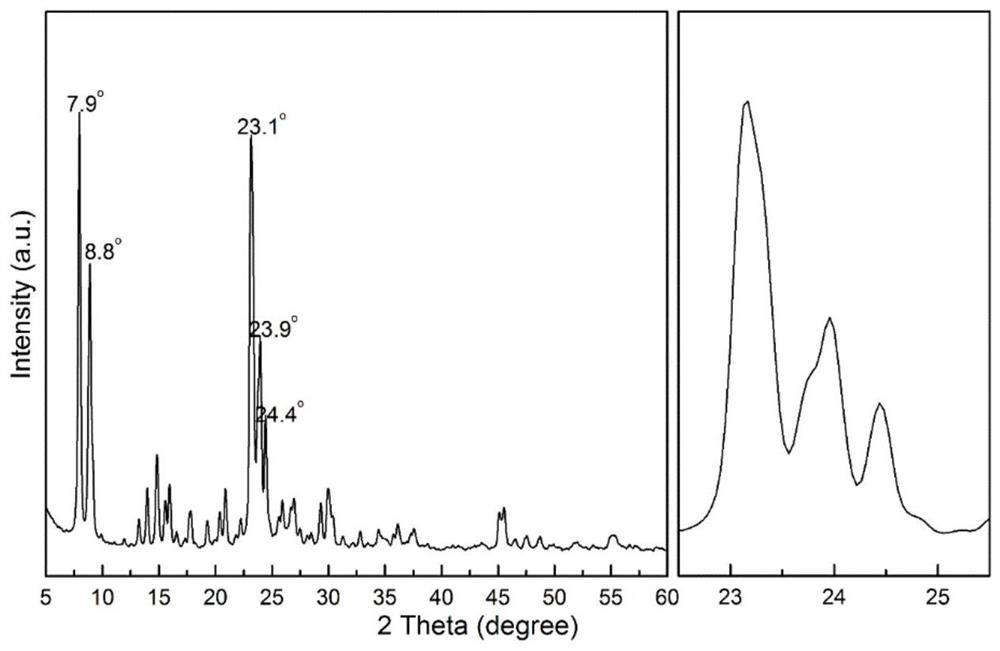

Image

Examples

Embodiment 1

[0030] (1) Add tetraethyl silicate dropwise to the tetrapropylammonium hydroxide solution with a mass fraction of 20%. The molar ratio of tetrapropylammonium hydroxide to tetraethyl silicate is 0.3:1. Stir for 6h to obtain a clear and transparent solution;

[0031] (2) Add titanium sulfate and vanadyl sulfate to the clear and transparent solution successively, the molar ratio of titanium sulfate to tetraethyl silicate is 0.03:1, and the molar ratio of vanadyl sulfate to tetraethyl silicate is 0.03:1 , stirred at room temperature for 6h until colorless;

[0032] (3) Add the structure regulator ammonium carbonate to the colorless solution, the molar ratio of ammonium carbonate to tetraethyl silicate is 0.05:1, stir at room temperature for 6h to obtain a uniform precursor solution, transfer it to a hydrothermal kettle for crystallization The crystallization temperature is 100°C and the crystallization time is 48h;

[0033] (4) The product in the hydrothermal kettle is separated...

Embodiment 2

[0036] (1) Tetraethyl silicate is added dropwise to a tetrapropylammonium hydroxide solution with a mass fraction of 22%. The molar ratio of tetrapropylammonium hydroxide to tetraethyl silicate is 0.3:1. Stir for 6h to obtain a clear and transparent solution;

[0037] (2) Add titanyl sulfate and vanadium trichloride successively to the clear transparent solution, the molar ratio of titanyl sulfate and tetraethyl silicate is 0.03:1, the molar ratio of vanadium trichloride and tetraethyl silicate 0.03:1, stirred at room temperature for 6h until colorless;

[0038] (3) Add the structure regulator ammonium sulfate to the colorless solution, the molar ratio of ammonium sulfate to tetraethyl silicate is 0.05:1, stir at room temperature for 6h to obtain a uniform precursor solution, transfer it to a hydrothermal kettle for crystallization The crystallization temperature is 100°C and the crystallization time is 48h;

[0039] (4) The product in the hydrothermal kettle is centrifuged,...

Embodiment 3

[0042] (1) Tetraethyl silicate is added dropwise to a tetrapropylammonium hydroxide solution with a mass fraction of 22%. The molar ratio of tetrapropylammonium hydroxide to tetraethyl silicate is 0.4:1. Stir for 6h to obtain a clear and transparent solution;

[0043] (2) Titanyl sulfate and vanadyl isopropoxide are successively added to the clear transparent solution, the molar ratio of titanyl sulfate and tetraethyl silicate is 0.04:1, the ratio of vanadyl isopropoxide to tetraethyl silicate The molar ratio is 0.04:1, stirred at room temperature for 6h until colorless;

[0044] (3) Add the structure regulator ammonium citrate to the colorless solution, the molar ratio of ammonium citrate to tetraethyl silicate is 0.1:1, stir at 40°C for 6 hours to obtain a uniform precursor solution, transfer to a hydrothermal kettle Crystallization was carried out in the middle, the crystallization temperature was 100°C, and the crystallization time was 48h;

[0045] (4) The product in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com