Pressure stabilizing system for accurately preparing ultrathin corneal endothelium graft

A technology with stable pressure and corneal endothelium, which is used in eye implants, ophthalmic surgery, etc., can solve the problems affecting the accuracy of corneal cutting and unstable corneal shape, and achieve the effect of maintaining shape and real-time fine-tuning of pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

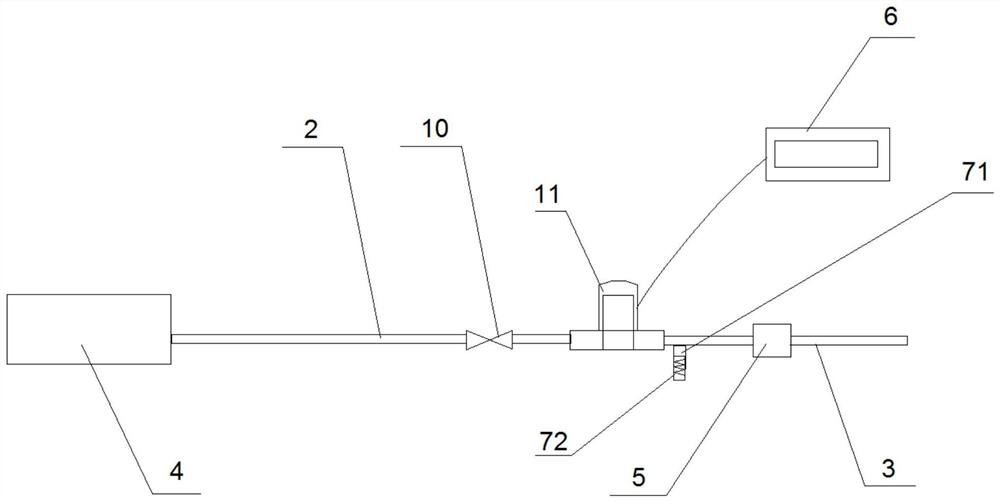

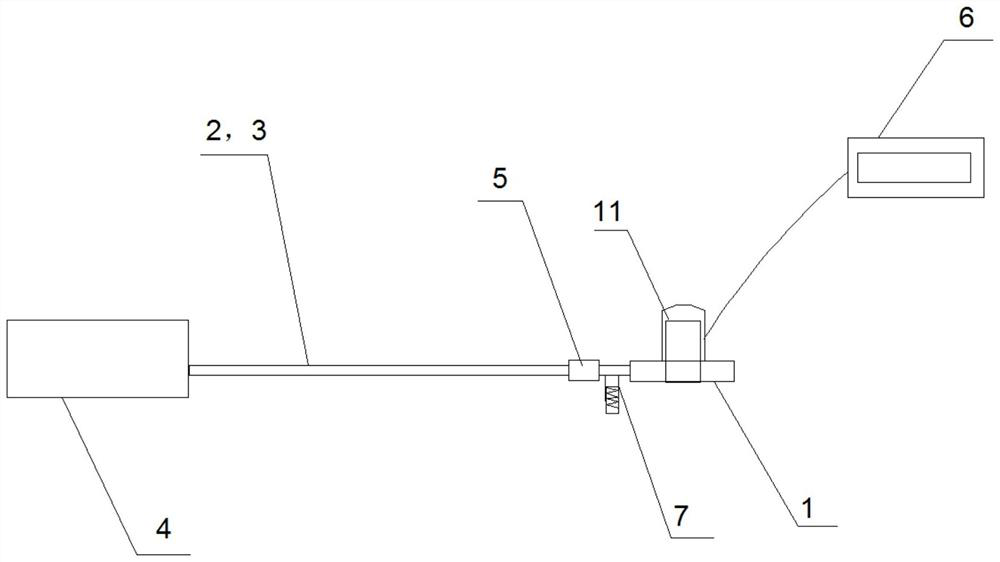

[0022] Such as figure 1 A pressure stabilization system for accurately preparing ultra-thin corneal endothelial grafts is shown, including an artificial anterior chamber stent 1 for cutting endothelial grafts from the isolated cornea (the artificial anterior chamber stent 1 used in this example is an existing technology, provided by the manufacturer of the corneal lamellar knife), the artificial anterior chamber support 1 is provided with a placement part 11 for placing the isolated cornea, and the artificial anterior chamber support 1 is provided with a flow channel (the flow channel That is, the passage between the balanced salt solution in the artificial anterior chamber stent and the upper cornea), the flow passage is connected with the placement part 11, and there is a liquid medium in the flow passage, and the liquid medium is a simulated anterior chamber Balanced salt solution of aqueous humor components, the artificial anterior chamber stent 1 is connected with a press...

Embodiment 2

[0025]The difference from Embodiment 1 is that the pressure stabilization mechanism 3 is also provided with a pressure fine-tuning device 7, and the pressure fine-tuning device includes a section of tubular buffer chamber 71, and a cock 72 is arranged in the buffer chamber , the cock 72 is provided with external threads, and the inner wall of the buffer chamber 71 is provided with internal threads, and the threaded cooperation between the cock 72 and the buffer chamber 71 realizes the fine adjustment of the space size of the buffer chamber 71 to achieve pressure stability Real-time adjustment of pressure in the piping structure of Mechanism 3. Before cutting, measure the corneal thickness and corneal curvature to adjust the position of the movable buckle. During the cutting process, the pressure change is observed, and the pressure change is controlled by adjusting the space of the buffer chamber 71 with the cock 72 of the pressure trimming device 7 .

Embodiment 3

[0027] The difference from Example 2 is that the artificial anterior chamber stent 1 is also provided with a pressure sensor and a display mechanism 6 for real-time detection of the internal pressure of the placement part 11, which can monitor the inside of the artificial anterior chamber stent and the cornea in vitro. The change and fluctuation of the medium pressure can be adjusted through the movable buckle 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com