Coating device

A technology of coating device and coating liquid, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc., can solve the problem of maintaining constant flow rate of difficult coating liquid, and achieve simple structure and uniform coating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

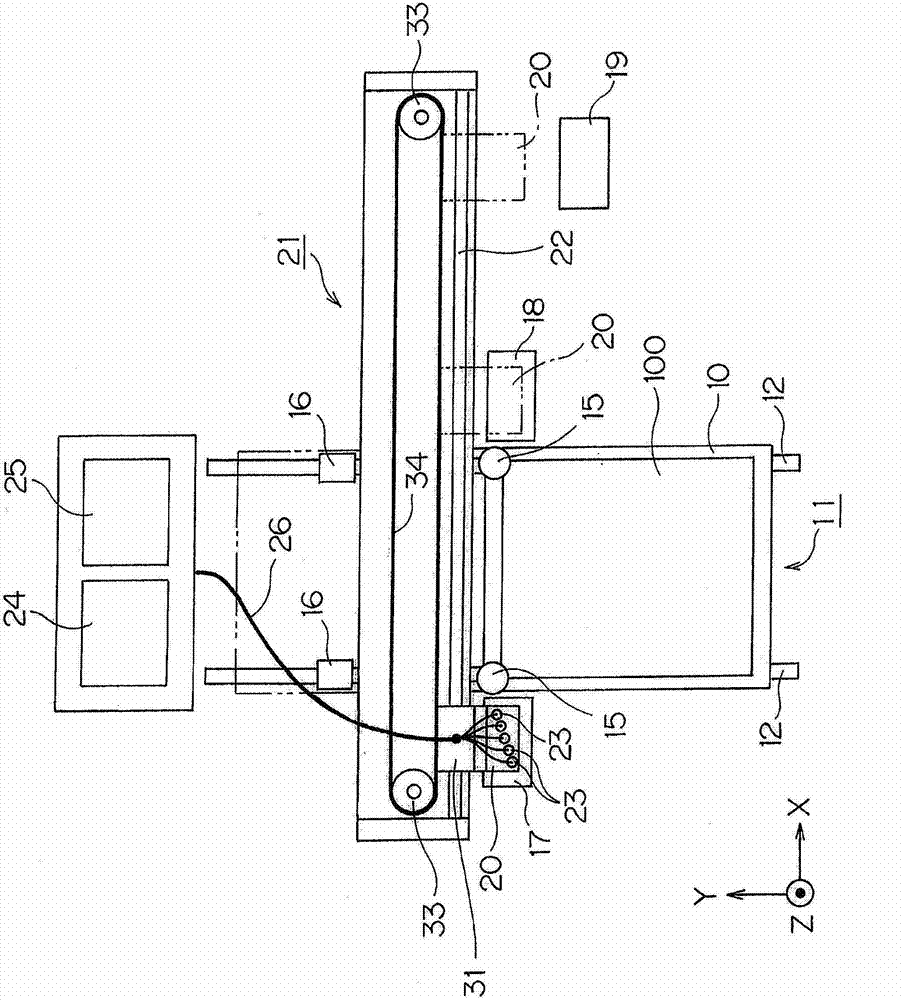

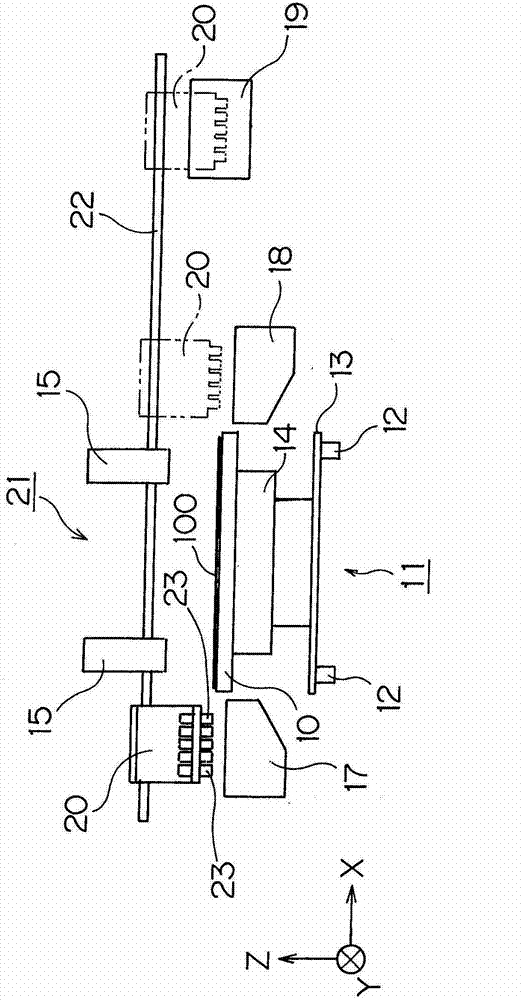

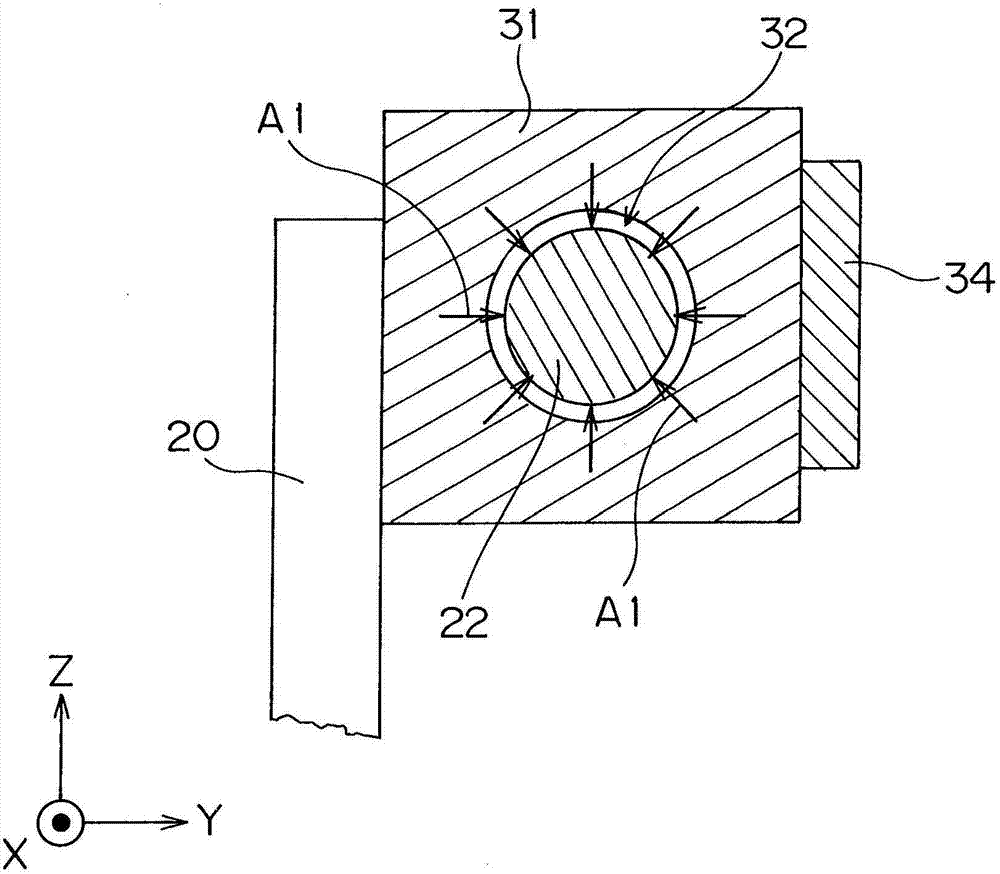

[0029] Embodiments of the present invention will be described below based on the drawings. figure 1 is a top view of the coating device of the present invention, figure 2 is the main view.

[0030] This coating device is used to coat a coating liquid on a rectangular glass substrate 100 . Specifically, the coating device is used to coat a volatile solvent (in this embodiment, one of the aromatic organic solvents) on the glass substrate 100 for the organic EL display device of the active matrix drive method. species of 4-methylanisole) and a coating solution of an organic EL material as a light-emitting material.

[0031] This coating apparatus has a substrate moving mechanism 11 for moving a glass substrate 100 . Such as figure 2 As shown, this substrate moving mechanism 11 has a substrate holding part 10 that holds the glass substrate 100 from the back surface of the glass substrate 100 . The substrate holding unit 10 is supported by a base 13 that moves along a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com