Wafer cleaning method and wafer cleaning equipment

A wafer and cleaning chamber technology, applied in the field of wafer cleaning methods and wafer cleaning equipment, can solve the problems of contamination of wafers by brush heads, waste of cleaning costs, large consumption of ultrapure water, etc., and achieves easy cleaning and breakthrough in usage Large, easy-to-float effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments.

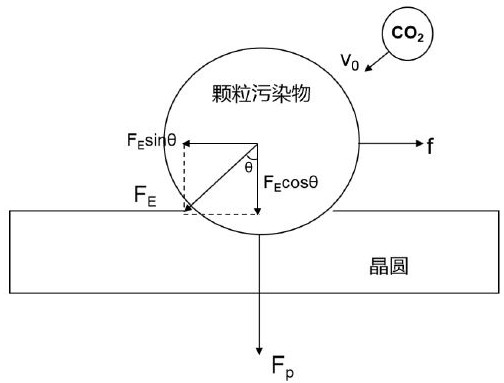

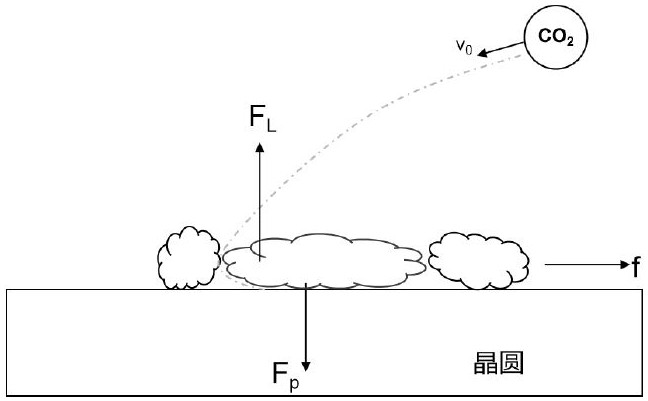

[0034] Please refer to figure 1 , is the temperature and pressure phase diagram of carbon dioxide. The carbon dioxide temperature and pressure phase diagram includes two curves of phase boundary line a and phase boundary line b and two points of the first characteristic point A and the second characteristic point B, wherein the first characteristic temperature of the first characteristic point A is t c is 304.04K and its upper and lower intervals, the first characteristic pressure p c is 7.39MPa and an interval fluctuating up and down, when the temperature of carbon dioxide is greater than or equal to the first characteristic temperature, and the pressure is greater than or equal to the first characteristic pressure, carbon dioxide is in a supercritical fluid state; when the temperature of carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com