A dual-fiber matrix coupling chip device

A dual optical fiber and chip technology, applied in the coupling of optical waveguide, optics, light guide, etc., can solve the problems of no coupling device and equipment, failure to effectively detect the proximity state, fragmentation of FA and CHIP, etc., and achieve the realization of the proximity state The effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

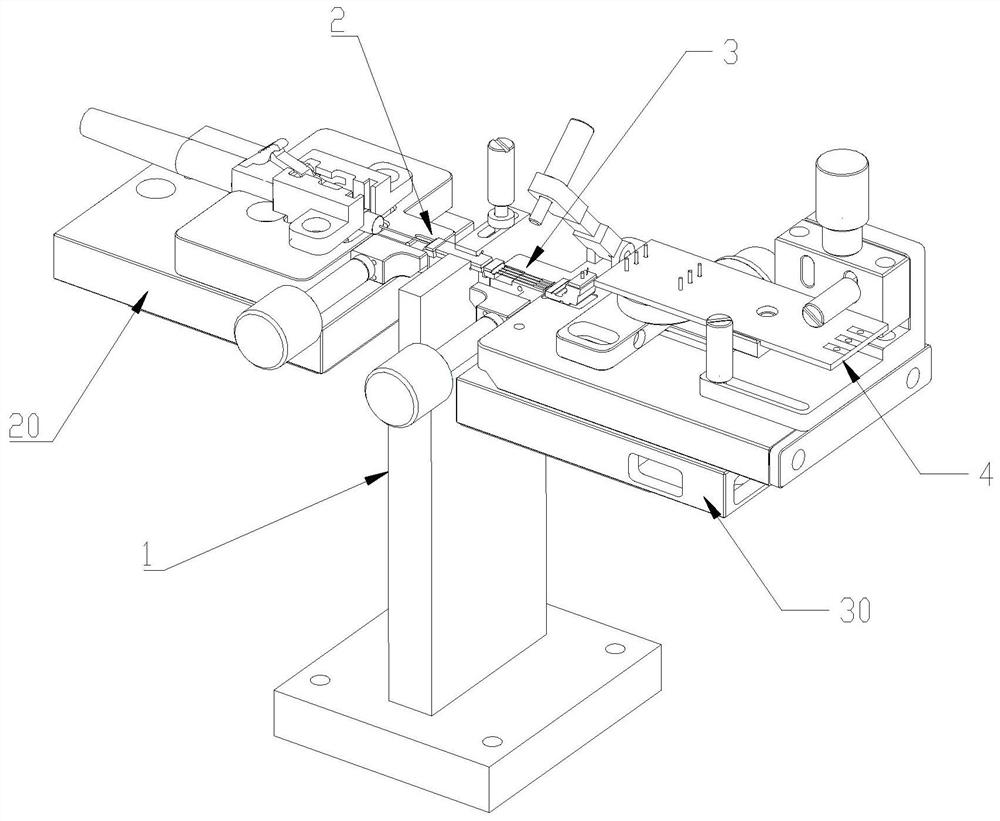

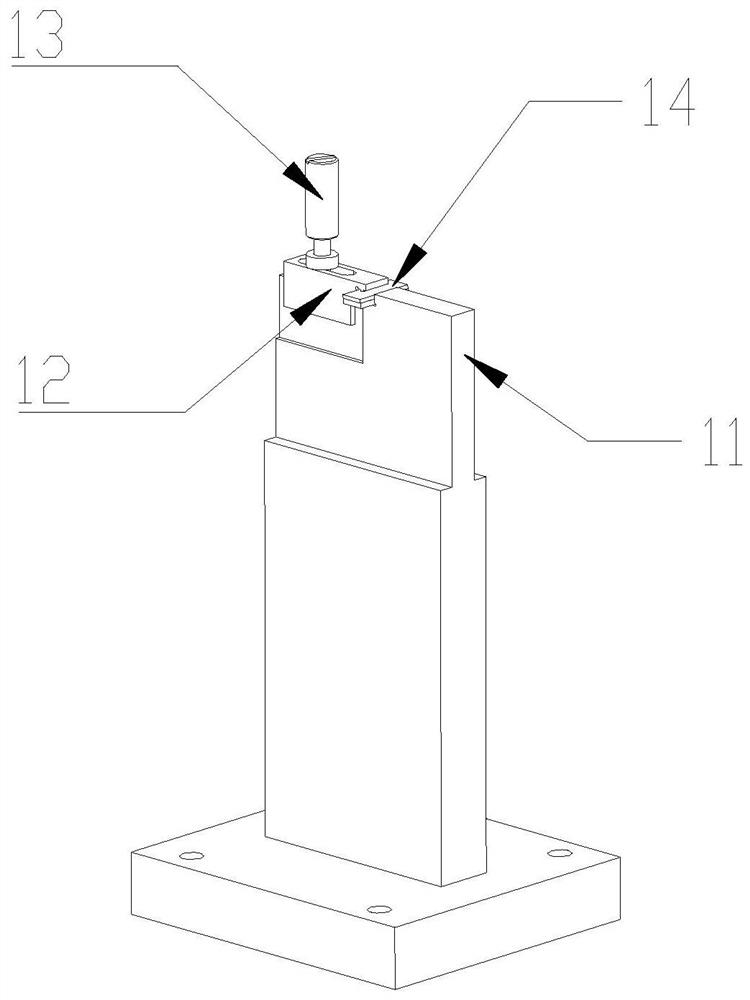

[0078] A dual-fiber matrix coupling chip device, see Figures 1 to 9 shown, including:

[0079] Chip fixing mechanism 1, which fixes the planar waveguide chip 14 thereon;

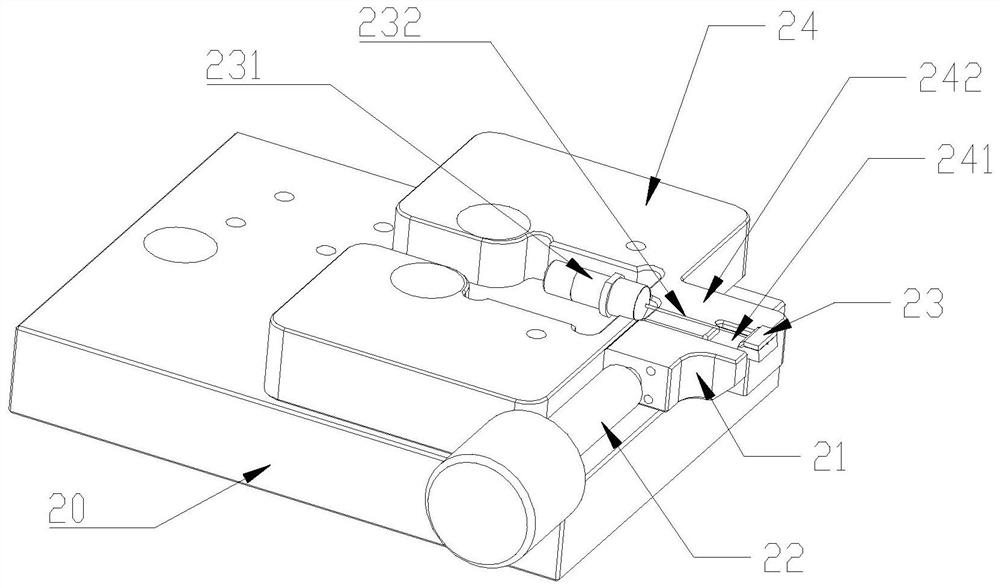

[0080] the first FA clamping mechanism 2, which is arranged on one side of the chip fixing mechanism 1, and is used for clamping the first FA 23 with the first pigtail 232;

[0081] The second FA clamping mechanism 3, which is arranged on the other side of the chip fixing mechanism 1, is used for clamping the second FA33 with the second pigtail;

[0082] Both the first FA clamping mechanism 2 and the second FA clamping mechanism 3 are provided with electric adjustment platforms at the bottom; respectively adjust the two electric adjustment platforms so that the light-transmitting surface of the first FA 23 is parallel to one end face of the chip 14, and The light-transmitting surface of the two FA33 is parallel to the other end surface of the chip 14;

[0083] A first bonding force detection member 20 an...

Embodiment 2

[0105] On the basis of Example 1, see Figure 5 As shown, it also includes an optical power detector 40 and a jumper steering buckle 332;

[0106] The jumper steering buckle 332 is arranged on the second platform 35, and is pressed on the second platform 35 through the board body 34; Turn to vertical delivery fiber. Specifically, one end of the plate body 34 is hinged to one end of the second platform 35 , and the other end of the plate body 34 is provided with a locking knob 341 penetrating through the plate body 34 . The locking knob 341 is connected to the other end of the second platform 35 . screwed. Then, the plate body 34 is pressed against the second platform 35 and the jumper steering buckle 332 is pressed against the second platform 35 at the same time.

[0107] The optical power detector 40 is arranged on the second platform 35 through the positioning connection mechanism 4;

[0108] By adjusting the positioning and connecting mechanism 4, the optical power dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com