Energy-saving assembly type building integrated system

A building and prefabricated technology, applied in the fields of heat exchange, energy saving and environmental protection, can solve the problems of large space occupancy rate of the wall, complex equipment composition, high investment cost, improve the efficiency of water and heat recovery, increase the latent heat of vaporization, The effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

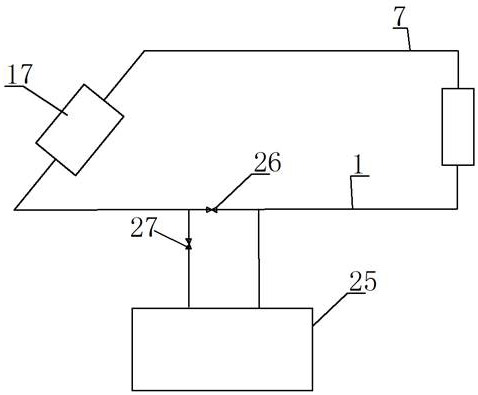

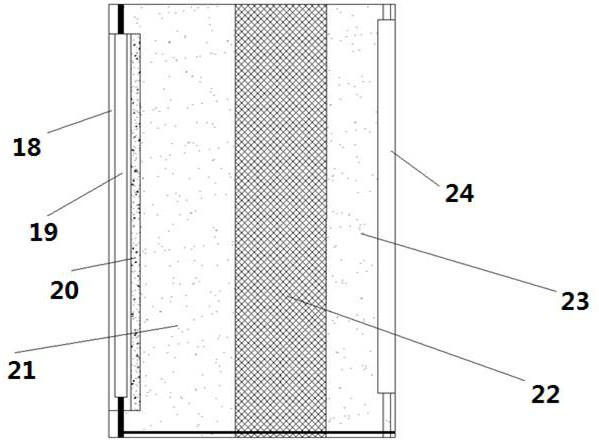

[0033] figure 1 A prefabricated building system is shown. Such as figure 1 As shown, the system includes a heater 17 and a prefabricated building 25 , the heater 17 communicates with the prefabricated building 25 , the air is heated in the heater 17 and then sent into the prefabricated building 25 . The building includes a prefabricated wall, the prefabricated wall such as diagram 2-1 , as shown in 2-2.

[0034] The heater is preferably a solar collector.

[0035] As shown in Figure 2-1, the wall body includes a transparent board 18, a preheating pipe 19, a thermal insulation layer 20, an outer load-bearing wall 21, an insulation layer 22, an inner load-bearing wall 23, and a ventilation part 24; the transparent board 18, The preheating pipe 19 and the heat insulating layer 20 are arranged on the outer surface of the outer bearing wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com