System and method for treating sludge through cooperation between thermal hydrolysis and cement kiln

A technology of thermal hydrolysis and cement kiln, which is applied in the direction of pyrolysis treatment of sludge, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., and can solve the problems affecting the process stability and reduction of incineration Effect discount, general dehydration effect, etc., to avoid the risk of leakage and pollution of the environment, enhance market competitiveness, and improve dehydration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

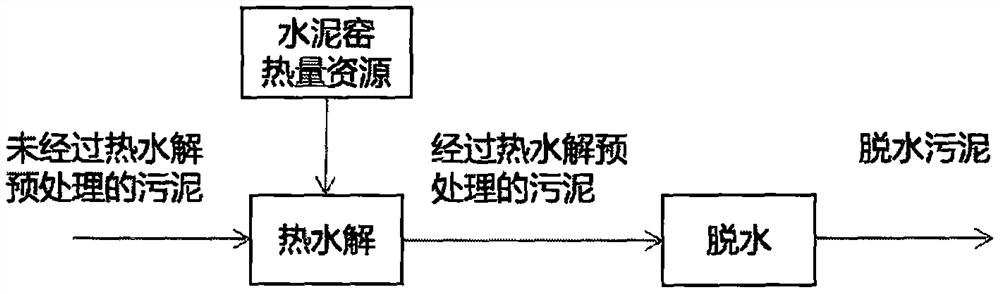

[0052] A method for thermal hydrolysis pretreatment in cooperation with cement kiln waste heat utilization for sludge disposal, the method comprising the following steps:

[0053] Step S1. Waste heat recovery, the cement kiln waste heat utilization device collects waste heat resources of the cement kiln, the cement kiln waste heat utilization device is a cement kiln, and the kiln tail flue gas of the cement kiln is used as the heat preservation heat source of the thermal hydrolysis treatment device, and is supplied to the thermal hydrolysis treatment use of the device;

[0054] Step S2. Thermal hydrolysis pretreatment. The sludge thermal hydrolysis pretreatment device performs thermal hydrolysis pretreatment on the sludge. The moisture content of the sludge is 85%. During the thermal hydrolysis pretreatment, the sludge enters the heat In the hydrolysis treatment device, the sludge is thermally hydrolyzed in the thermal hydrolysis treatment device 1 for 30 minutes to carry out ...

Embodiment 2

[0058] The difference from Example 1 is that the step of collecting sludge is also included.

[0059] A method for thermal hydrolysis pretreatment in conjunction with cement kiln waste heat utilization and disposal of sludge, specifically comprising the following steps:

[0060] Step S1. Collect the sludge, collect the sludge from the primary sedimentation tank and the secondary sedimentation tank of the sewage treatment plant. The sludge not only contains a large amount of organic matter and plant nutrients such as nitrogen and phosphorus, but also has a certain amount of pathogenic microorganisms, heavy metals and Poisonous and harmful substances that are difficult to degrade;

[0061] Step S2. Waste heat recovery, the cement kiln waste heat utilization device collects the waste heat resources of the cement kiln, the cement kiln waste heat utilization device is a cement kiln, and the kiln head flue gas of the cement kiln is used as the heat source of the sludge thermal hydro...

Embodiment 3

[0066] A method for thermal hydrolysis pretreatment in cooperation with cement kiln waste heat utilization for sludge disposal, the method comprising the following steps:

[0067] Step S1. Waste heat recovery, the cement kiln waste heat utilization device collects waste heat resources of the cement kiln, the cement kiln waste heat utilization device is a cement kiln waste heat boiler, and the steam of the waste heat boiler is used as the heat source of the thermal hydrolysis treatment device for use by the thermal hydrolysis treatment device ; Step S2. Thermal hydrolysis pretreatment, the sludge thermal hydrolysis pretreatment device performs thermal hydrolysis pretreatment on the collected sludge, the water content of the sludge is 85%, during the thermal hydrolysis pretreatment process, the sludge The sludge enters the sludge thermal hydrolysis pretreatment device, and the sludge is thermally hydrolyzed in the sludge thermal hydrolysis pretreatment device for 30 minutes to ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com