AT-cut temperature compensation crystal oscillator of comb-shaped metal film

A temperature-compensated crystal oscillator and metal film technology, applied in impedance networks, electrical components, etc., can solve problems such as crystal oscillator performance impact, load effect, and increase the overall quality of the electrode area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

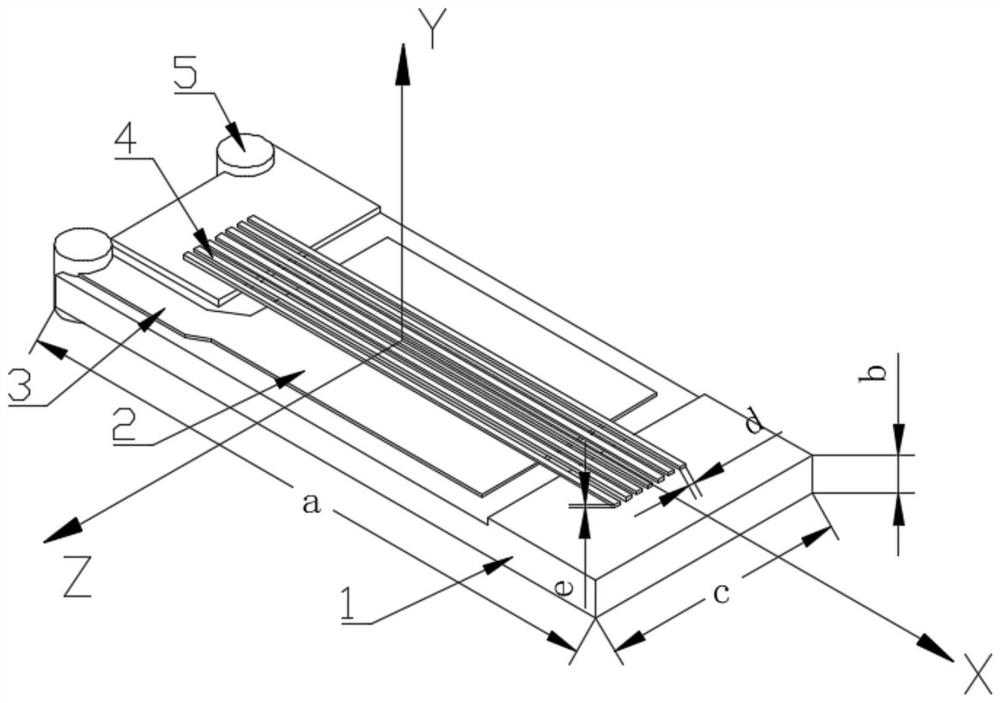

[0026] like figure 1 As shown, an AT temperature-compensated crystal oscillator of a comb-shaped metal film mainly includes a 1-quartz wafer, the quartz wafer is a cuboid, and the upper and lower surfaces are rectangular, and the upper surface (placed with a comb-shaped metal film) has two rectangular convex platform; the upper and lower surfaces of the rectangular quartz wafer are respectively plated with a center electrode 2, a corner of the center electrode 2 has an extension layer 3, and the end of the extension layer 3 is connected to the glue point 5, and the glue point 5 is the lead-out end of the center electrode 2; The vertical axis direction of the upper surface of the quartz wafer 1 is set as the X axis, the horizontal axis direction is set as the Z axis, and the direction perpendicular to the upper surface of the quartz wafer 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com