Planar parallel mechanism device driven by double five-bar mechanisms, and control method thereof

A mechanism device, five-bar mechanism technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of the influence of the transmission accuracy of the mechanism, the energy loss of the reducer, etc., to achieve smooth and fast motion, reduced precision, drive and control good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

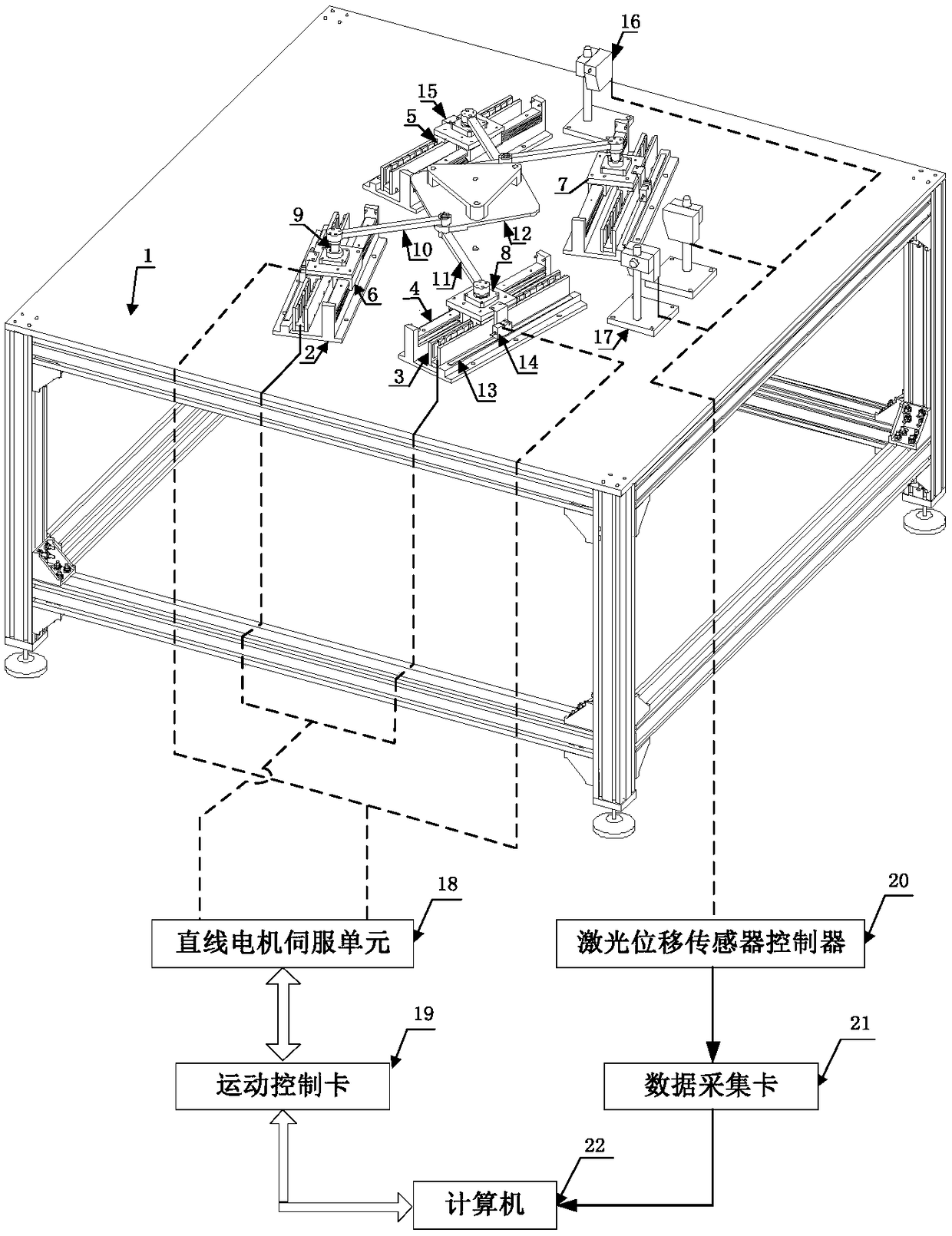

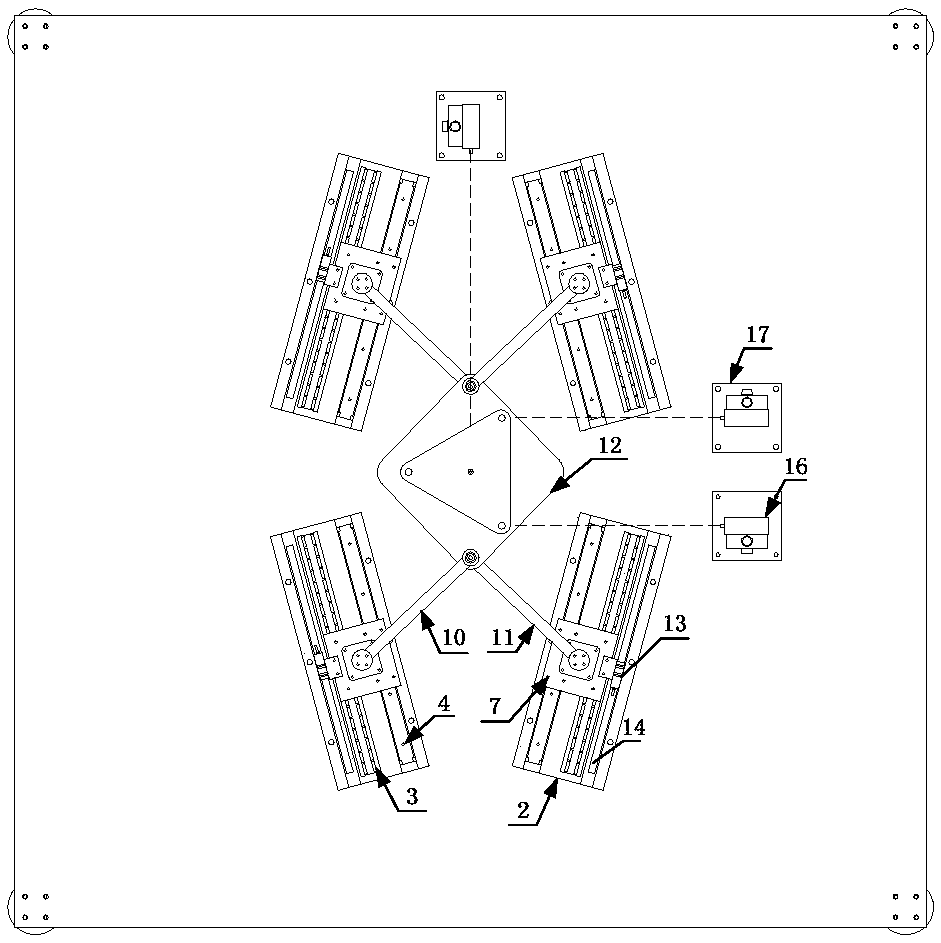

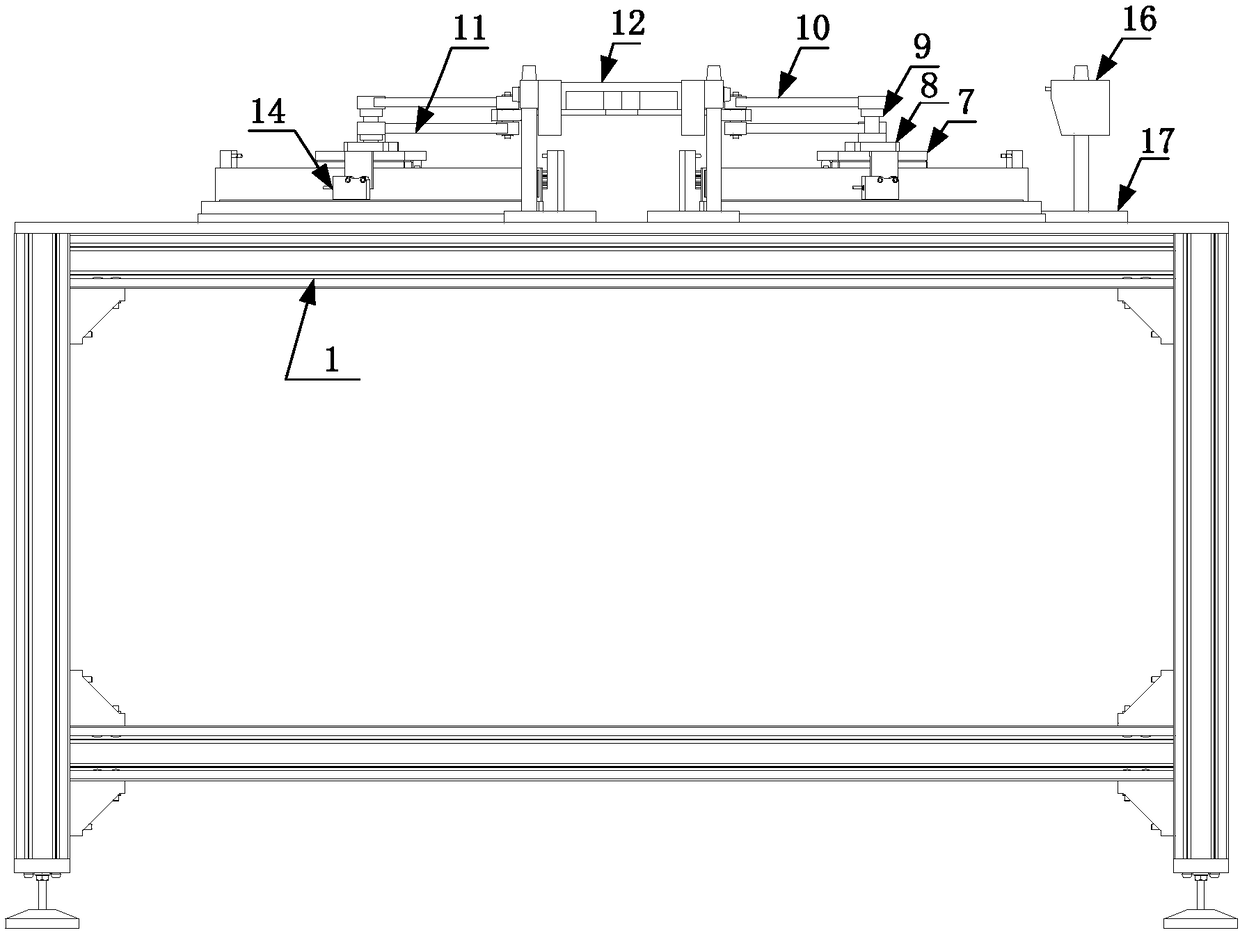

[0049] Such as Figure 1-Figure 6 As shown, a planar parallel mechanism device and control method driven by a double five-bar mechanism, its hardware equipment includes a parallel mechanism body part, a detection part and a control part;

[0050] The body part of the parallel mechanism includes two planar five-bar mechanisms, a moving platform 12 and a static platform 1, and the static platform 1 is a square profile seat, which is used as a test bench to support the whole device. The moving platform 12 is divided into two parts, the lower part is a parallelogram platform, wherein two bearing holes are arranged at the upper and lower diagonal positions, and is connected with each driving branch chain through a rotating shaft, and the upper part is an equilateral triangle platform.

[0051]The two planar five-bar mechanisms have the same structure, both including two rigid driven rod body units, and the two rigid driven rod body units have the same structure, both including a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com