Airtight waveguide-microstrip transition structure

A transition structure and waveguide technology, applied in the microwave field, can solve problems such as the inability to guarantee the air tightness of the waveguide and the components, and achieve the effect of avoiding signal leakage and ensuring electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

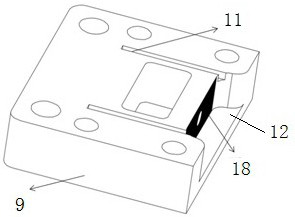

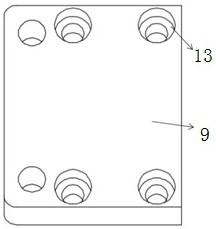

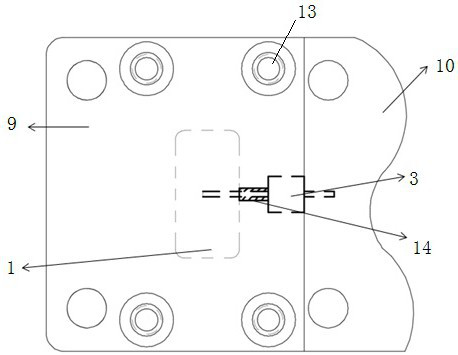

[0037] Such as Figure 1-4 As shown, the airtight waveguide-microstrip transition structure disclosed in this implementation includes a waveguide cavity 1 and an airtight cavity 2 for installing a microstrip circuit. The waveguide cavity 1 and the microstrip circuit are electrically connected through glass beads 3 . specific:

[0038] The waveguide cavity 1 includes an upper cavity 9 and a lower cavity 10, the bottom of the upper cavity 9 is open, the top of the lower cavity 10 is open, the bottom of the upper cavity 9 is attached to the top of the lower cavity 10, and the lower cavity 10 The side wall of the glass bead 3 is connected to the side wall of the airtight cavity 2, and the glass bead 3 is located between the upper cavity 9 and the airtight cavity 2, and one end of the pin of the glass bead 3 passes through the side wall of the upper cavity 9, and the pin The other end passes through the side wall of the airtight chamber 2 .

[0039] As a preferred matching method...

Embodiment 2

[0042] Such as Figure 5 As shown, in this embodiment, on the basis of Embodiment 1, in order to avoid the influence of the existence of the air cavity on the performance of the waveguide-microstrip transition structure, when designing the pin hole of the glass bead 3, its diameter should be 50Ω Impedance matching design, therefore, the air cavity 14 here will not affect the transition structure.

Embodiment 3

[0044] Such as Figure 6 , Figure 7 As shown, on the basis of Embodiments 1 and 2, the lower cavity 10 of this embodiment is manufactured integrally with the airtight chamber 2 and processed separately as part A15. The bottom of the airtight chamber 2 is provided with a window, and the window is provided with a cover plate 8; Process the upper cavity 9 as part B.

[0045] When the present invention is assembled, the glass bead 2 is first sintered into the prefabricated glass bead mounting hole of the part A, and then the part B is fixed on the part A with screws; since the inner conductor of the glass bead 3 needs to enter the inside of the waveguide, as The probe is used to receive the signal transmitted by the waveguide port, so the two parts that make up the waveguide cannot be assembled from the vertical direction, but can only be assembled from the horizontal direction.

[0046] In order to ensure the accuracy of assembly and eliminate the errors caused by assembly, two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com