Double-floating sealing test device for simulating muddy water working condition

A sealing test, double floating technology, applied in the direction of measuring the increase and decrease rate of the fluid, using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the shaft deformation, the difficulty of installing the double floating seal with large shaft diameter, and the axial force Unbalance and other problems can be solved to reduce the test error, avoid the shafting movement and the increase of the main shaft deflection, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] For ease of understanding, the specific structure and working method of the present invention are further described as follows:

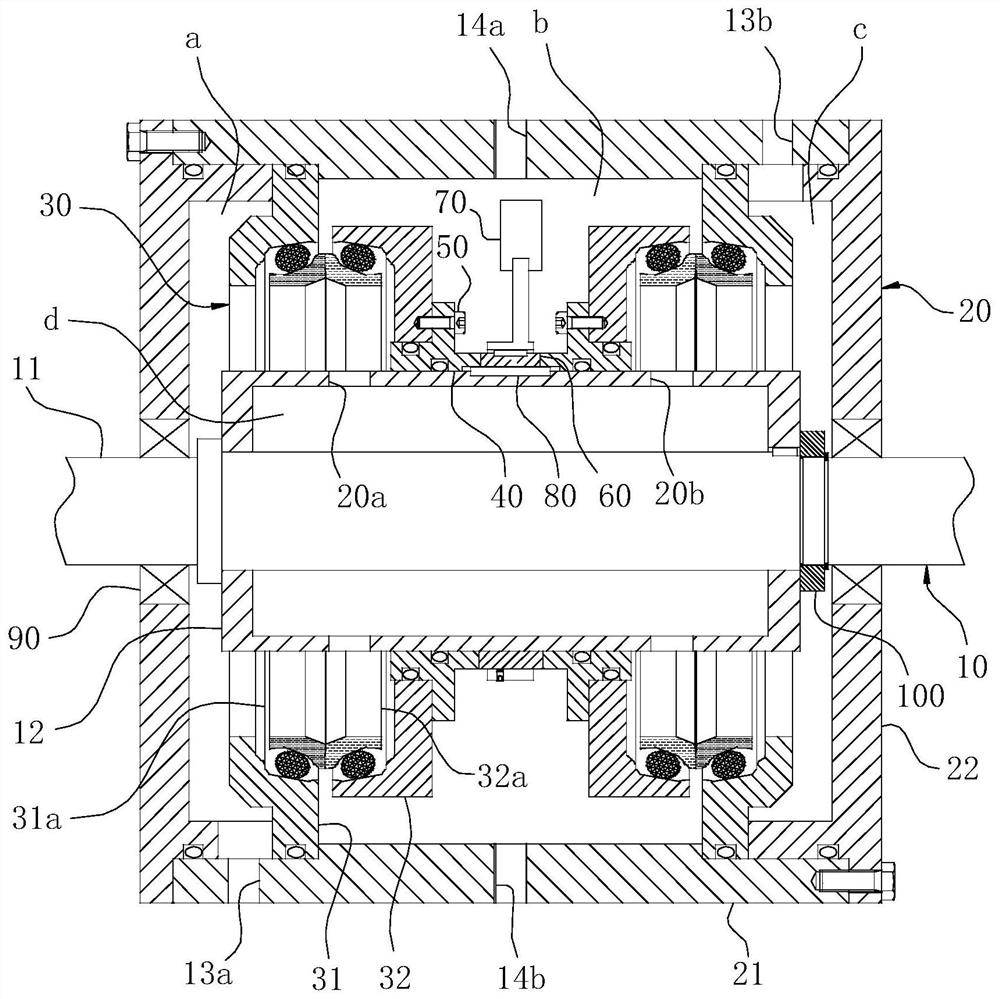

[0033] The concrete implementation structure of the present invention refers to Figure 1-3 As shown, the main structure includes a housing 20 and two sets of symmetrically distributed double floating seals 30 located in the inner cavity of the housing 20, wherein:

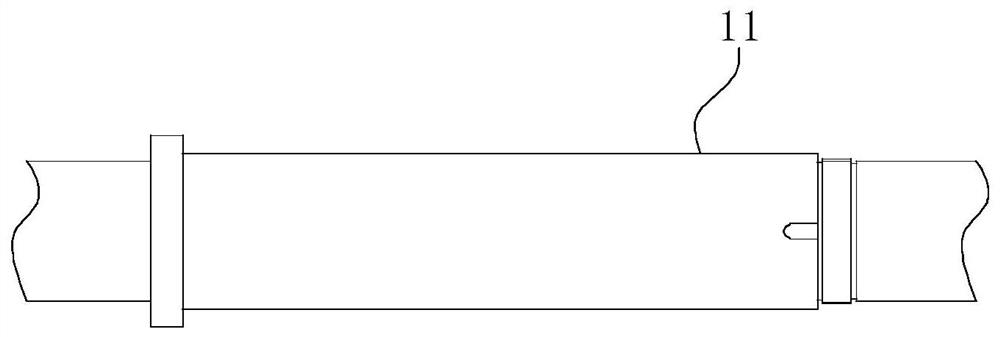

[0034] The main shaft 10 is composed of a shaft body 11 and a shaft sleeve 12 keyed on the shaft body 11. The shaft sleeve 12 is sleeved and pressed against the figure 2 After the shaft shoulder of the shaft body 11 shown, rely on the tightening action of the axial nut 100 to axially compress the shaft sleeve 12 on the shaft shoulder; if necessary, additional Arrange snap rings or snap rings, etc., to play the anti-loosening function; of course, other fixed fit methods can also be used in actual operation. The housing 20 includes an outer cylinder 21 and a left-right symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com