Rapid food drying machine

A fast drying and food technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of food moisture regain, incomplete drying, food pollution, etc., and achieve high drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

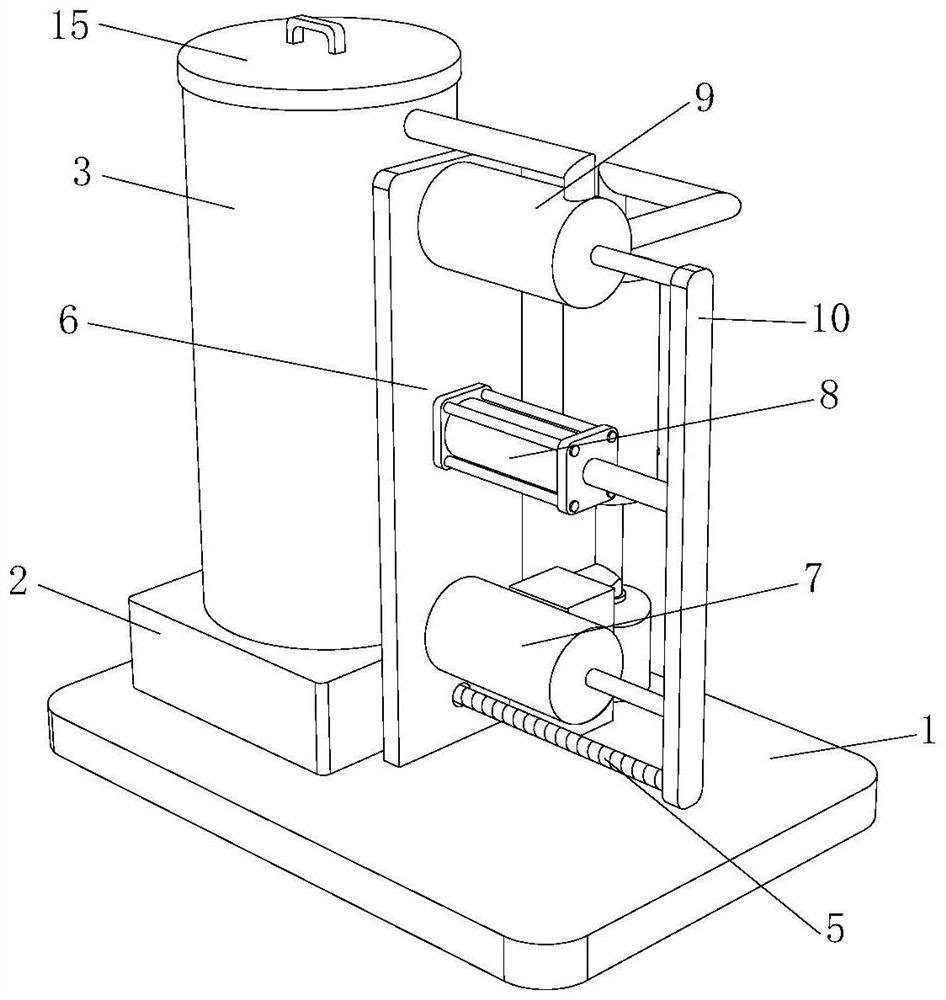

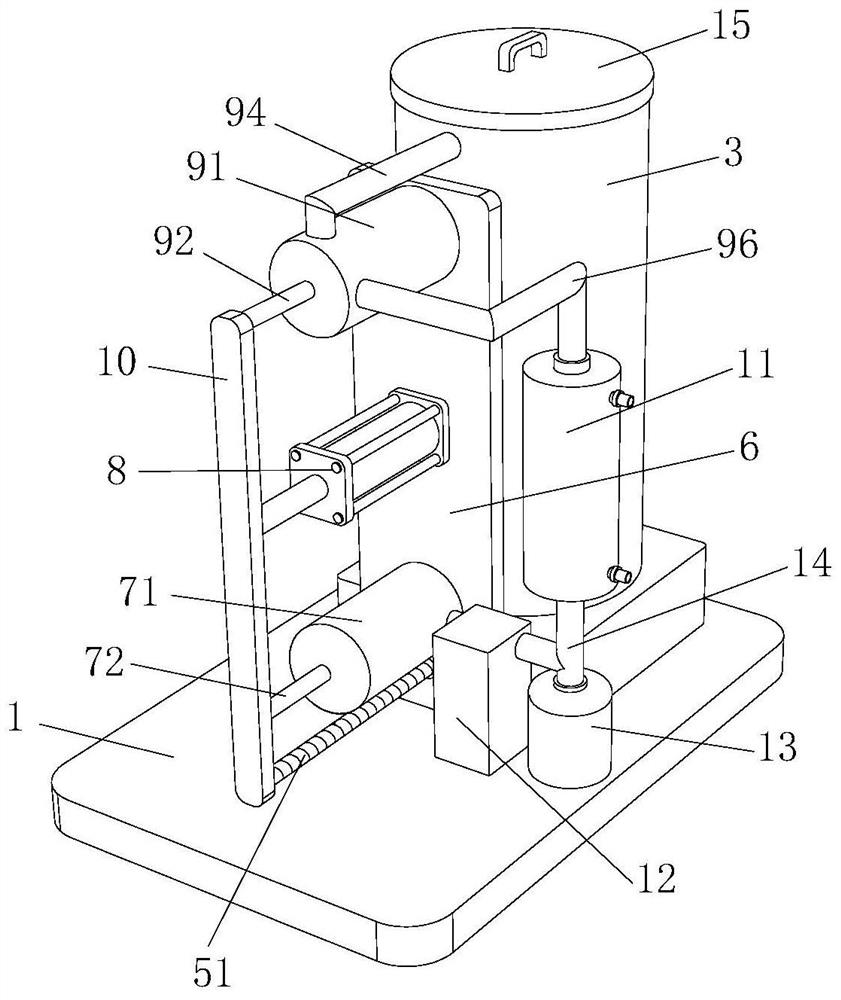

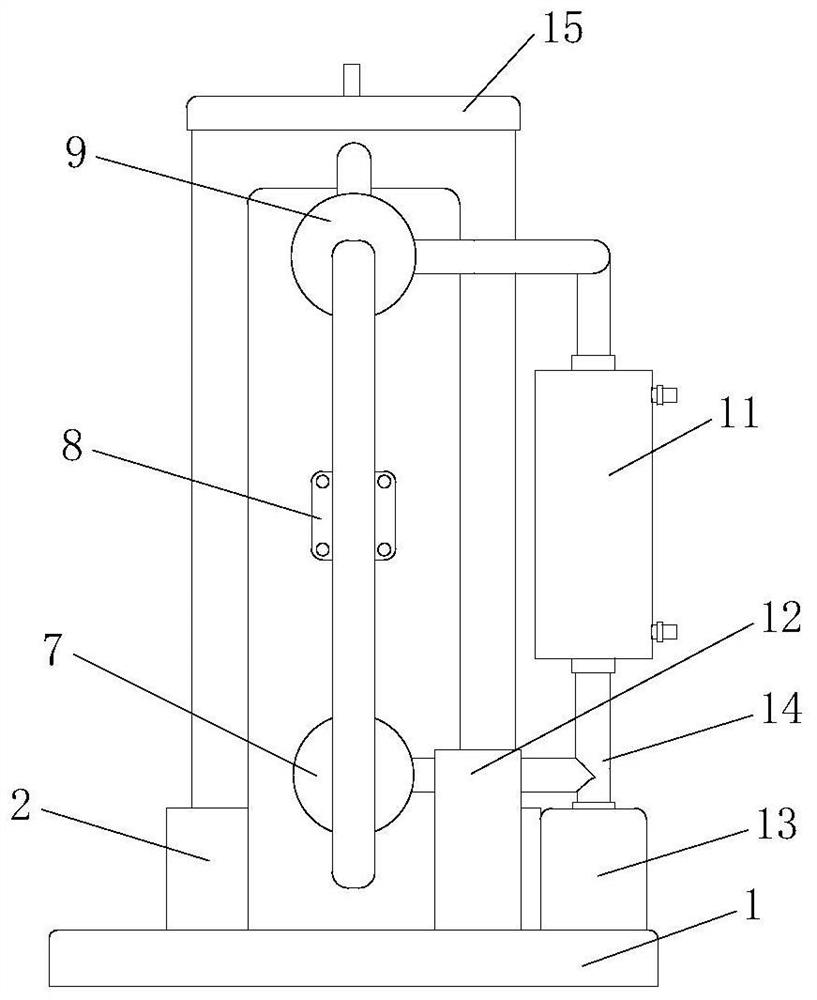

[0039] Such as Figure 1 to Figure 4 As shown, a food quick drying machine includes a base 1, a transmission box 2 is fixedly installed on one side of the top of the base 1, a tank body 3 is fixedly installed on the top of the transmission box 2, and the inside of the tank body 3 The cavity is rotated and installed with a drying barrel 4, the barrel wall of the drying barrel 4 is a porous structure, so that the gas can enter and exit the drying barrel 4, and the inner cavity of the transmission box 2 is provided with a transmission mechanism 5 for driving the drying barrel 4 to rotate. The bottom of the outer wall of the tank body 3 is fixedly connected with an air injection device 7 for blowing hot air, the air inlet end of the air injection device 7 is fixedly connected with a heating device 12 for providing hot air, and the top of the outer wall of the tank body 3 is fixedly connected with a useful Air extraction device 9 for extracting moisture.

[0040] During specific u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com