Electrolytic hydrogen production system and temperature control method and device thereof

A temperature control method and technology of a temperature control device, which are applied to electrolysis components, electrolysis processes, cells, etc., can solve the problems of changes in the input power of electrolyzers, affecting the effect of temperature regulation, and delaying the action of regulating valves, so as to improve the safety performance of the system. and operation reliability, improve temperature regulation effect, and improve the effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

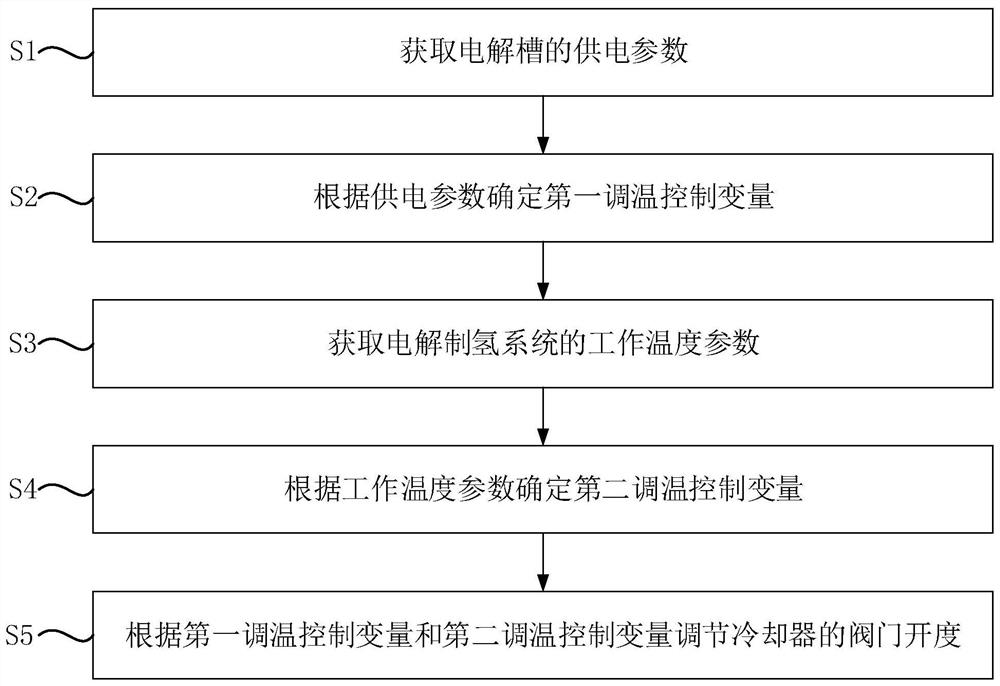

[0049] figure 1 It is a flow chart of a temperature control method for an electrolytic hydrogen production system provided in Embodiment 1 of the present invention. This embodiment is applicable to an electrolytic hydrogen production system that uses a new energy power supply as a hydrogen production power supply. The hydrogen production power supply is used for electrolysis The electrolyzer of the hydrogen production system supplies power, and the electric energy provided by the hydrogen production power supply fluctuates, and the method can be performed by a temperature control device configured with corresponding functional modules and / or software programs.

[0050] In this embodiment, the electrolytic hydrogen production system includes an electrolytic cell, a hydrogen-oxygen-liquid separator, a cooler, a circulating pump, and a control unit. A valve is set at the inlet end of the cooling liquid of the cooler, and the control unit adjusts the cooling liquid by adjusting the...

Embodiment 2

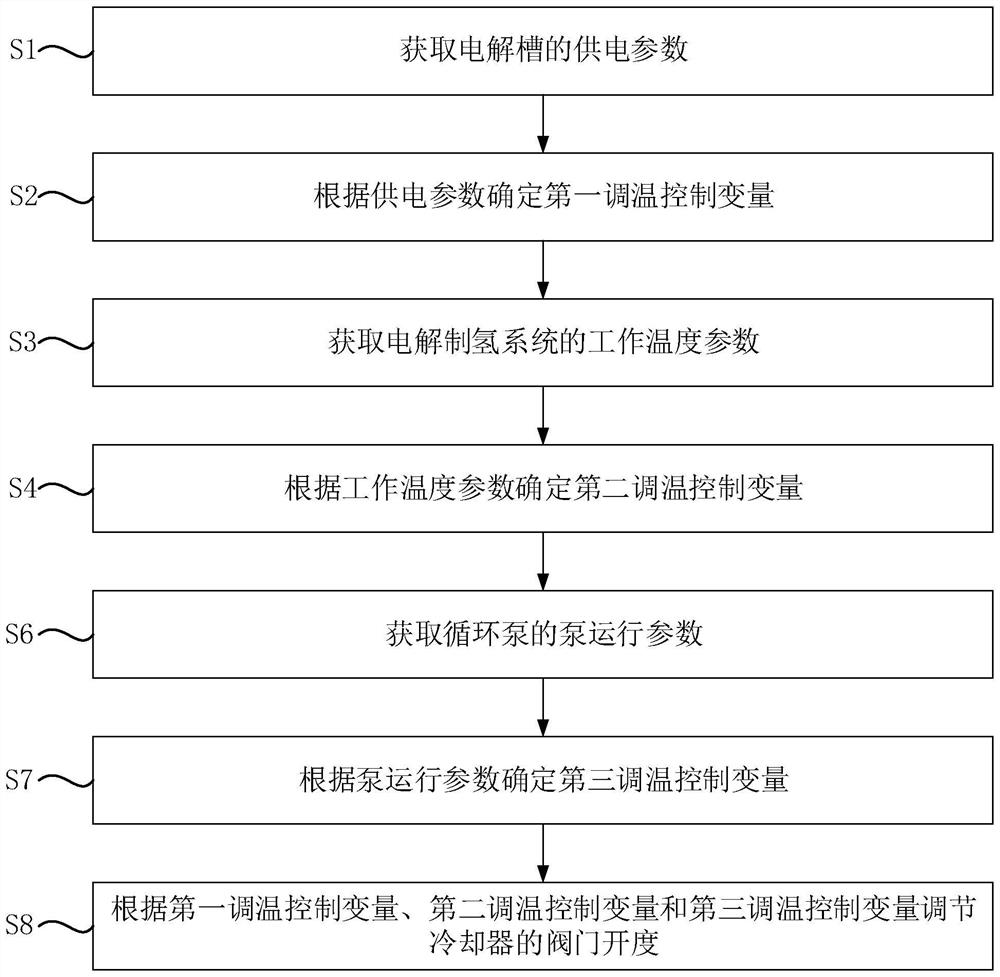

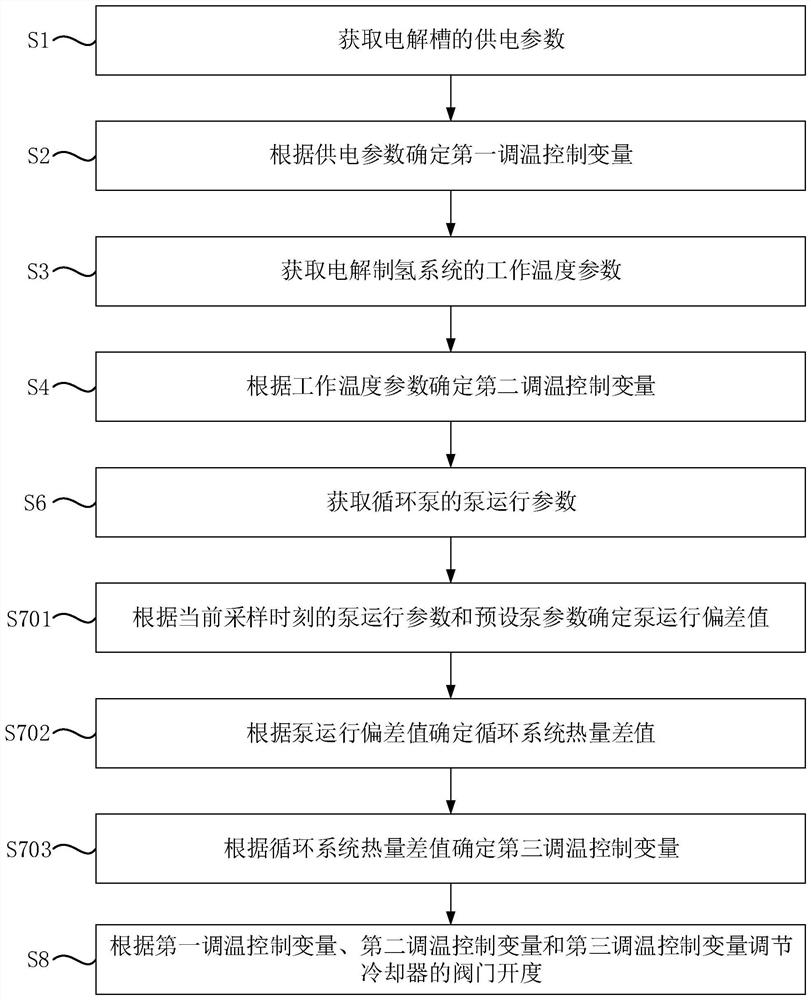

[0072] figure 2 It is a flow chart of a temperature control method for an electrolytic hydrogen production system provided in Embodiment 2 of the present invention. exist figure 1 On the basis of the illustrated embodiment, this embodiment adds a technical solution of detecting the pump operation parameters of the circulating pump and calculating the feedforward compensation control variable.

[0073] Such as figure 2 As shown, the temperature control method specifically includes the following steps:

[0074] Step S1: Obtain the power supply parameters of the electrolyzer.

[0075] Step S2: Determine the first temperature adjustment control variable according to the power supply parameters.

[0076] Step S3: Obtain the operating temperature parameters of the electrolytic hydrogen production system.

[0077] Step S4: Determine the second temperature regulation variable according to the working temperature parameter.

[0078] Step S6: Obtain the pump operating parameters...

Embodiment 3

[0101] Based on any of the above-mentioned embodiments, Embodiment 3 of the present invention provides a temperature control device for an electrolytic hydrogen production system. The temperature control device provided in the embodiment of the present invention can execute the temperature control method provided in any embodiment of the present invention. It has the corresponding functional modules and beneficial effects of the execution method.

[0102] Figure 4 It is a schematic structural diagram of a temperature control device for an electrolytic hydrogen production system provided in Embodiment 3 of the present invention.

[0103] Such as Figure 4 As shown, the temperature control device 00 includes: a power supply parameter acquisition unit 10 , a temperature detection unit 20 and a control unit 30 . Among them, the power supply parameter acquisition unit 10 is used to acquire the power supply parameters of the electrolyzer; the temperature detection unit 20 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com