Smokeless coal charging method for eliminating dust and smoke on top of coke oven

A technology of smokeless coal charging and coke oven, which is applied in the direction of furnace safety devices, coke ovens, separation methods, etc., can solve the problems of ineffective recovery of raw gas, loss of raw gas, return of raw gas, etc., and achieve good economic benefits and Environmental benefit, reduction of production cost, effect of increasing collection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The coal type used in this example is blended coal from the production plant, and the proportion of blended coal with a particle size of less than 3 mm is 85%. The coking process used is a combination of coal humidity control process and conventional coking process.

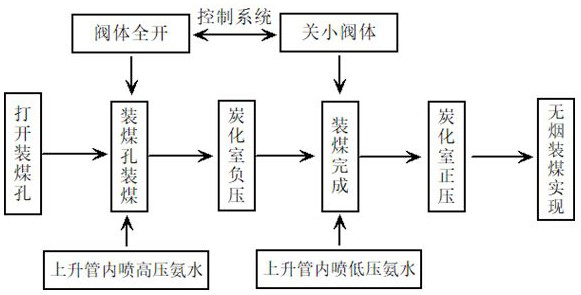

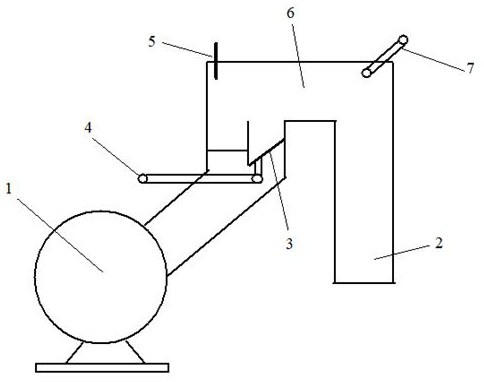

[0039] When opening the coal charging hole of the coke oven and starting coal charging, the pneumatic device 4 is used to control the valve body flap 3 to fully open, and the ammonia injection device 7 is used to spray high-pressure ammonia water at the same time. The pressure of the ammonia water is 20MPa. During the coal loading process, the opening of the valve body flap 3 is controlled by the pneumatic device 4, combined with the control of the ammonia injection pressure by the ammonia injection device 7, the pressure of the riser pipe 2 is a negative pressure of 510 Pa, that is, Ensure that the pressure in the carbonization chamber of the coke oven is a negative pressure of 510Pa, and the negative pres...

Embodiment 2

[0045] The coal type used in this example is blended coal from the production plant, and the proportion of blended coal with a particle size of less than 3 mm is 80%. The coking process used is a combination of coal humidity control process and conventional coking process.

[0046] When opening the coal charging hole of the coke oven and starting coal charging, the pneumatic device 4 is used to control the valve body flap 3 to fully open, and the ammonia injection device 7 is used to spray high-pressure ammonia water at the same time. The pressure of the ammonia water is 25 MPa. During the coal loading process, the opening of the valve body flap 3 is controlled by the pneumatic device 4, combined with the control of the ammonia injection pressure by the ammonia injection device 7, the pressure of the riser pipe 2 is negative pressure 530Pa, that is, Ensure that the pressure in the carbonization chamber of the coke oven is a negative pressure of 530Pa, and the negative pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com