Foamable composite material composition, foamed composite material and preparation method and application thereof

A composite material and composition technology, applied in the field of composite materials, can solve the problems of uncontrollable expansion ratio and low compressive strength of composite materials, and achieve the effect of ensuring uniformity, mechanical strength and excellent compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

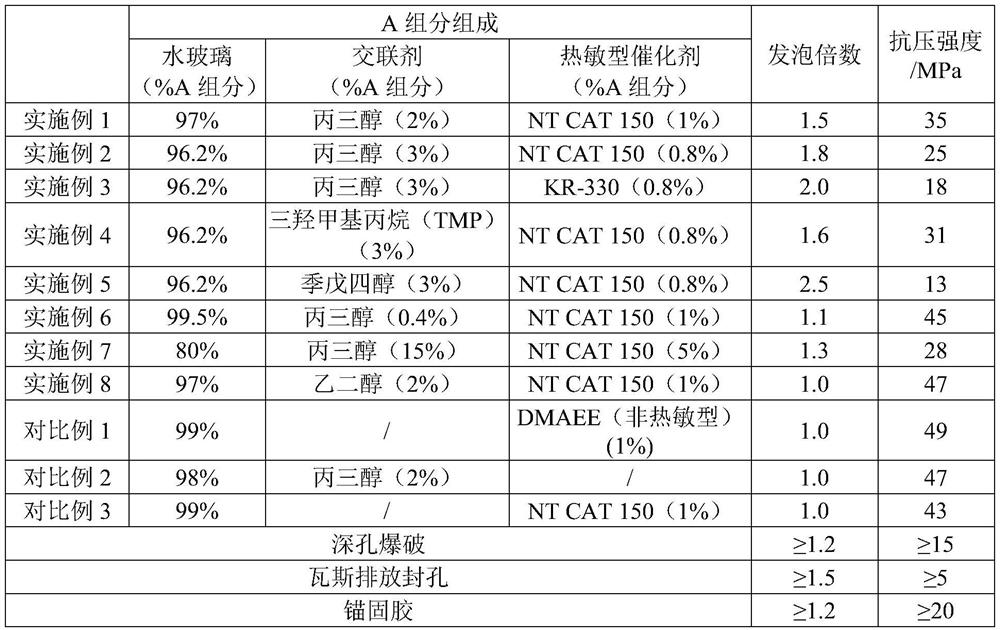

Examples

Embodiment 1-8

[0097] (1) Preparation of component A

[0098] According to the ratio shown in Table 1, sodium silicate solution (content 47%, modulus 2.6) was sequentially added to the reactor, and a crosslinking agent and a heat-sensitive catalyst were added during stirring. Stir for 30 minutes to obtain a clear and transparent component A product.

[0099] (2) Preparation of polyisocyanate prepolymer

[0100] Add 80 parts by weight of polyphenyl polymethylene polyisocyanate into the reaction kettle, add 20 parts by weight of polyether polyol during stirring, and stir for 60 minutes to obtain a brown polyisocyanate prepolymer.

[0101] (3) Preparation of B component

[0102] Add 93 parts by weight of polyisocyanate prepolymer into the reaction kettle, add 7 parts by weight of diethylene glycol butyl ether acetate during stirring, and stir for 30 minutes to obtain a brown transparent component B product.

[0103] (4) C component is fly ash, comes from Guohua Sanhe Power Plant, and it is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com