Preparation method of 3-methylthiopropionaldehyde

A technology for the crude product of methionaldehyde and methionaldehyde, which is applied in the field of preparation of 3-methylthiopropionaldehyde, can solve the problems of resource waste, impact on yield, and ineffective recovery, and achieve cost savings and enhanced Degree of dissociation, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

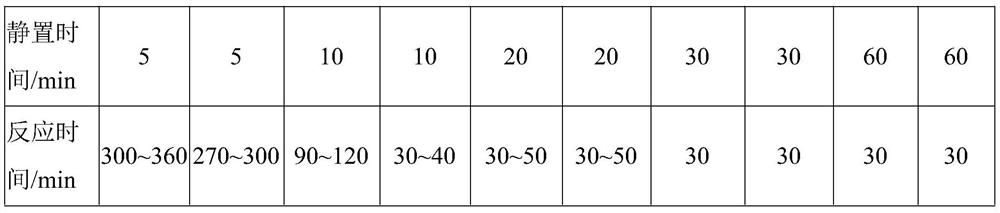

[0028] Take 1000g of crude MMP prepared by conventional production methods, add 100g of water, keep warm at 30°C, prepare 10 groups, and stir for 10 minutes until the system is white, start timing from the stop of stirring, and take out at 5, 10, 20, 30, and 60 minutes The lower MMP of the two groups of samples, a total of 10 groups, each with a mass of 400g; the remaining 10 groups of upper samples were respectively added with 100g of 99wt% AC and 88.6g of 97.6wt% MC to react at 30°C. When the sum of the mass fractions of MC and AC in the system is less than 1%, the timing is stopped, and the standing separation time and addition reaction time of each group are recorded, see Table 1.

[0029]

[0030] Table 1

Embodiment 2

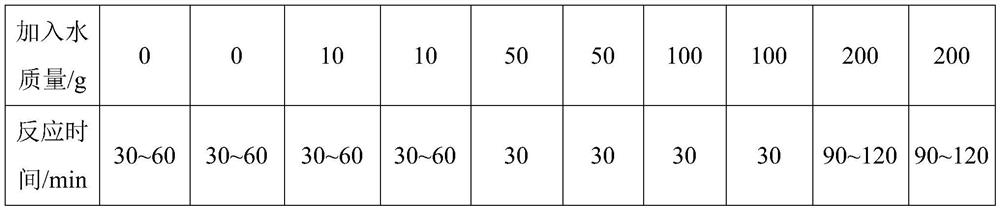

[0032] Take 1000g of refined MMP (the content of MMP is 99.4wt%, the content of methyl mercaptan is 0.13wt%, and the content of acrolein is 0.05wt%), add 1g of glacial acetic acid and 0.67g of pyridine, prepare 10 groups, and add water to each group 0, 10, 50, 100, 200g, then add 100g 99wt% AC, 88.6g 97.6wt% MC, react at 30°C, the stirring speed is 500r / min, start timing from the addition of MC, until the MC in the system When the sum of the mass fractions of AC and AC is less than 1%, the timing is stopped, and the standing separation time and addition reaction time of each group are recorded, see Table 2.

[0033]

[0034] Table 2

Embodiment 3

[0036] Take MMP10 groups prepared by conventional methods, each group has a mass of 1000g, add 0, 50, 100, 150, and 200g of water to each group, keep stirring at 30°C for 15min until emulsified, let stand for 30min, remove all MMP in the lower layer, and heat at 90°C , Under the relative pressure of -0.01bar, remove the low-boiling point substances until their total mass fraction is less than 1wt%, and detect the heavy component content of the residue. The low-boiling point substances are detected by gas chromatography, and the substances with boiling points lower than MMP are all classified as light components. The test results are shown in Table 3.

[0037]

[0038] table 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com