Full-automatic double-head wafer testing machine

A wafer test, fully automatic technology, applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., to achieve the effect of improving accuracy and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

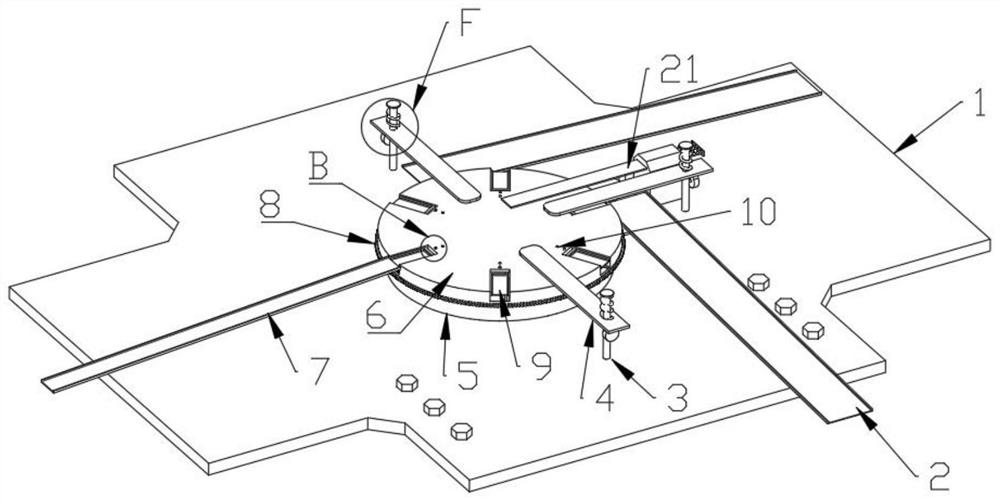

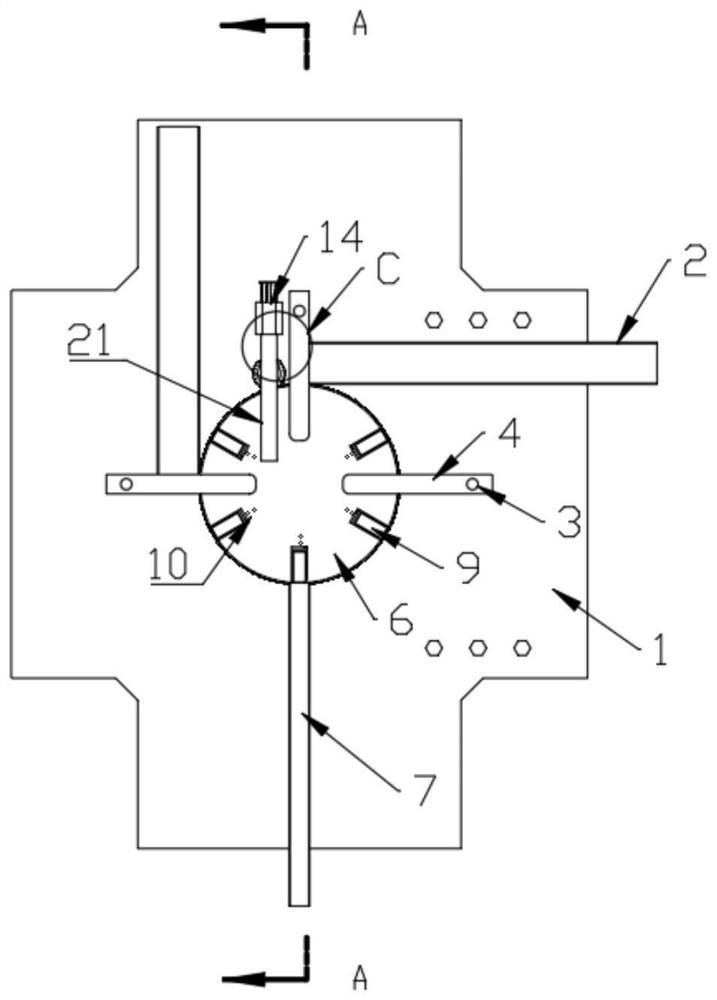

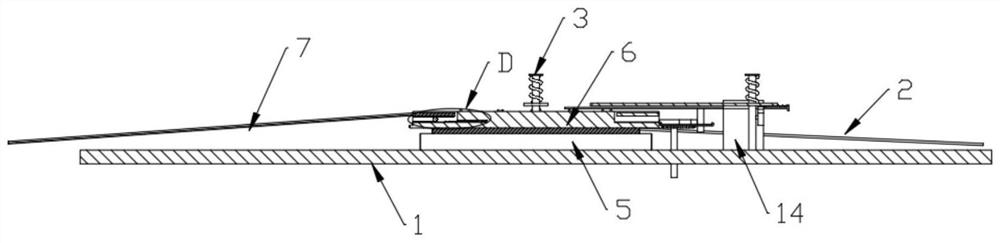

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0029] refer to Figure 1-10 , a fully automatic double-head wafer testing machine, including a test platform 1 and an electric turntable 5 installed on the upper end of the test platform 1. The rotating end of the electric turntable 5 is fixedly connected to a test disc 6. There are multiple equidistant distributions on the edge of the upper end of the test disc 6. The mounting groove 11 of the mounting groove 11 is slidably connected with a receiving plate 9 adapted to the wafer. The surface of the receiving plate 9 is provided with a groove, one side of which is open, and its size is adapted to the wafer, and the wafer can be positioned within it to limit For detection, different receiving plates 9 can be replaced according to the size of the wafer, so that different wafers can be detected.

[0030] The upper end of the test board 6 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com